It's always good to try early prototypes of new technology, because although some fall by the wayside, plenty don’t. One such clever device is the electrically powered supercharger, generally used in conjunction with a traditional turbocharger to banish turbo lag, initially on diesel engines but now on petrol, too.

With the current trend towards down-speeding of engines (lower revs to reduce friction losses), they’re even more relevant. Low revs equal reduced exhaust energy – worse on diesels because the exhaust is cooler in the first place. The trend to engine downsizing has a similar effect.

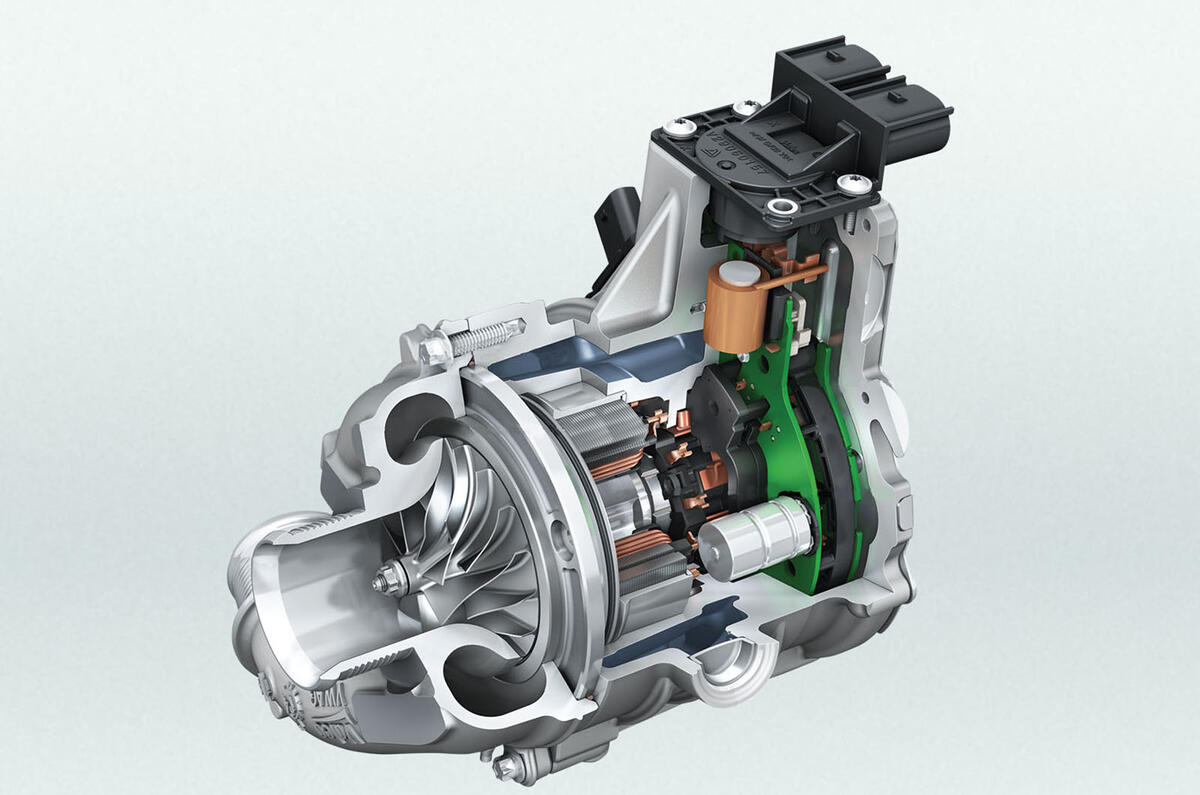

One of the first major manufacturers out of the traps with production electric supercharging was Audi, which showed a prototype Audi A6 with an electric supercharger system in 2013. Positioned between the turbo and engine, the electric supercharger was bypassed most of the time until the engine management system detected exhaust pressure was too low to deliver decent response from the turbo. At that point, valves in the exhaust would open to bring the electric supercharger on stream, giving almost instantaneous boost.

It was pretty cool and the engineer riding shotgun could switch the system on and off to show how laggy the engine felt without the electrical assistance. At the time, the 48V system needed to drive the compressor motor was still a few years off, but now electric superchargers are in production with several manufacturers, including Audi, Mercedes-Benz and, as of earlier in 2019, Jaguar Land Rover (JLR) with a new straight six petrol Ingenium engine.

Audi’s system positions the electric supercharger close to the engine intake and downstream of the intercooler. The charge air isn’t cooled, but on the Audi SQ5, for example, it makes only 1.4 bar of boost, the compressor instantly spooling to 65,000rpm when it’s needed. Beyond that, the conventional turbo takes over and the electric supercharger is dialled out of the equation with valves and turned off. On bigger engines, the spec gets busier and more expensive, the Audi SQ8 getting an electric booster in addition to its bi-turbos.

There’s yet to be an example of electric supercharging on small-capacity engines of, say, 1.0-litre or less in production. That’s not to say the idea of extreme downsizing hasn’t been explored, though.

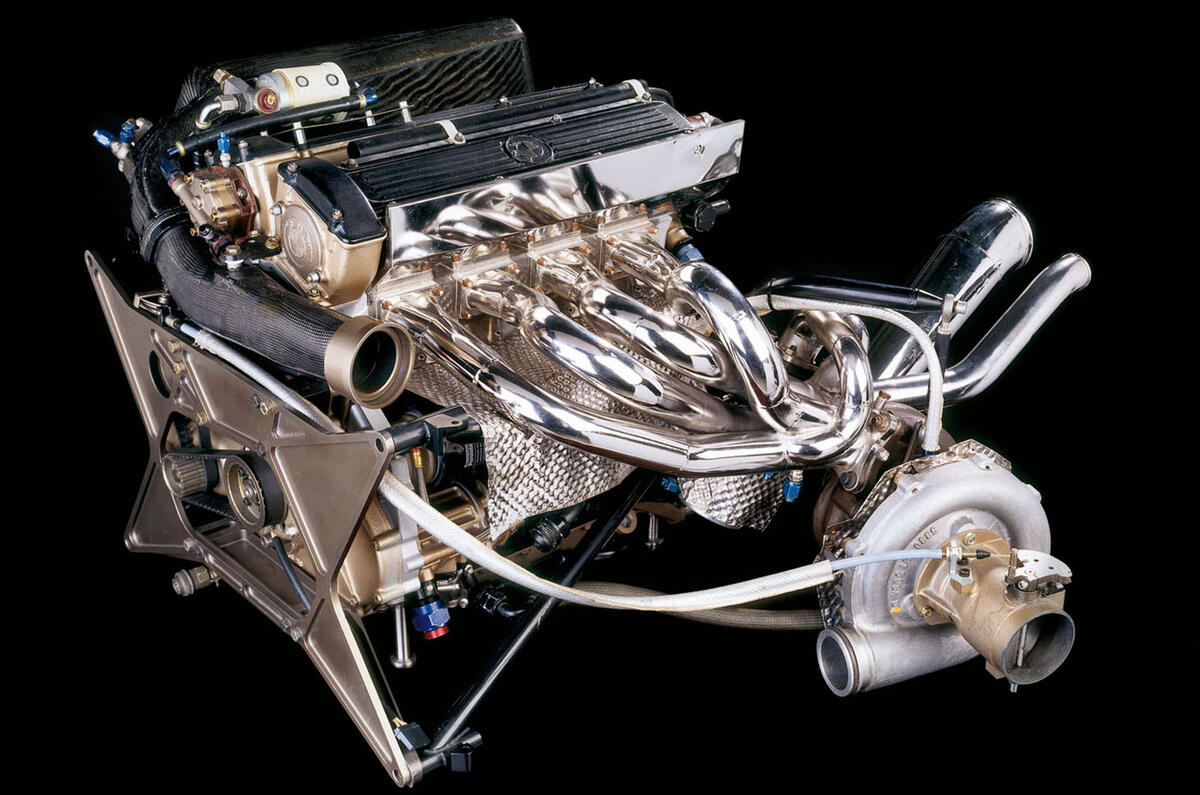

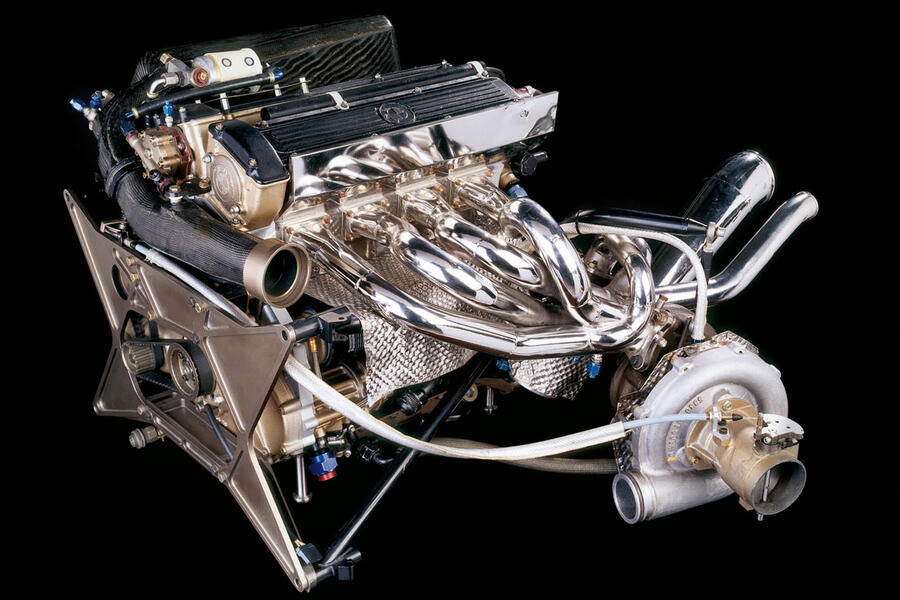

The Hyboost project masterminded by a consortium including Ricardo and Ford a few years ago did just that, aiming to emulate the power, torque and drivability of a baseline Ford Focus 2.0-litre model using a 1.0-litre Ecoboost engine. So, too, did the Ultraboost with Supergen project in which both JLR and Lotus Engineering were involved. The aim there was to produce the power and drivability of a 5.0-litre V8 from a 2.0-litre four-cylinder engine. The Hyboost project used the electric supercharger in the normal way, but also for “exhaust energy recapture by electric turbo-compounding”, which means using the turbo as an exhaust-driven generator to convert unwanted heat energy in the exhaust into electricity to be stored in the battery.

Join the debate

Add your comment

There's yet to be an example

It's a supercharger

I'm pretty sure they are right. A turbo is driven directly by exhaust gases. If ir's electrically powered then it's a supercharger, even if the electrical power is derived from an exhaust-driven turbine.

That's a turbo.

It's a supercharger

Since the article is about a compressor powered by a motor (there is no turbine), it would be totally wrong to call it a 'turbo'.

Electric supercharger is as good name as any.