Relax: a quarter of a century from now, those of us who enjoy driving will still be turning the steering wheel, pressing the pedals and shifting the gearlever with our own limbs, via inputs from our brains and feedback from our senses.

At least, we hope we will, because we’re not quite ready to change the masthead of this website to ‘Autonomouscar’. That doesn’t have a good ring to it at all.

It isn’t getting any easier to be a keen driver or a maker of performance cars. As the years grind on, manufacturers are coming under increasingly intense legislative pressure to improve safety and efficiency and reduce pollution while at the same time facing pressure from their own executive boards to sell more cars and make them more cheaply.

Rest assured that car makers are not hell bent on forcing us to let the machines do all the work all of the time, though. Most manufacturers rely on a strong emotional link with drivers to sell their latest models. As drivers, we connect with our cars for myriad reasons: the way they look, smell and feel, how they save us time and money, but also how they drive.

We’d wager that Autocar readers aren’t interested in getting into an anonymous, autonomous box-on-wheels and emerging at the other end of their journey without having had any input into the process.

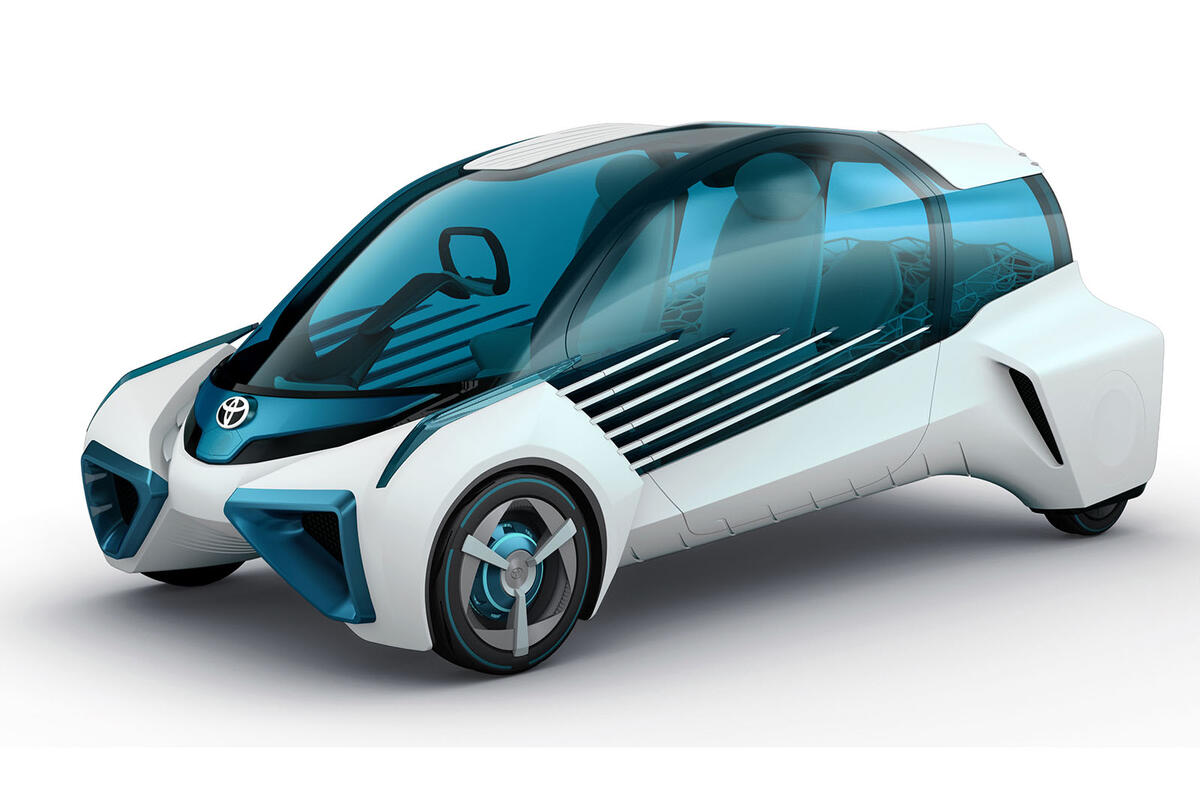

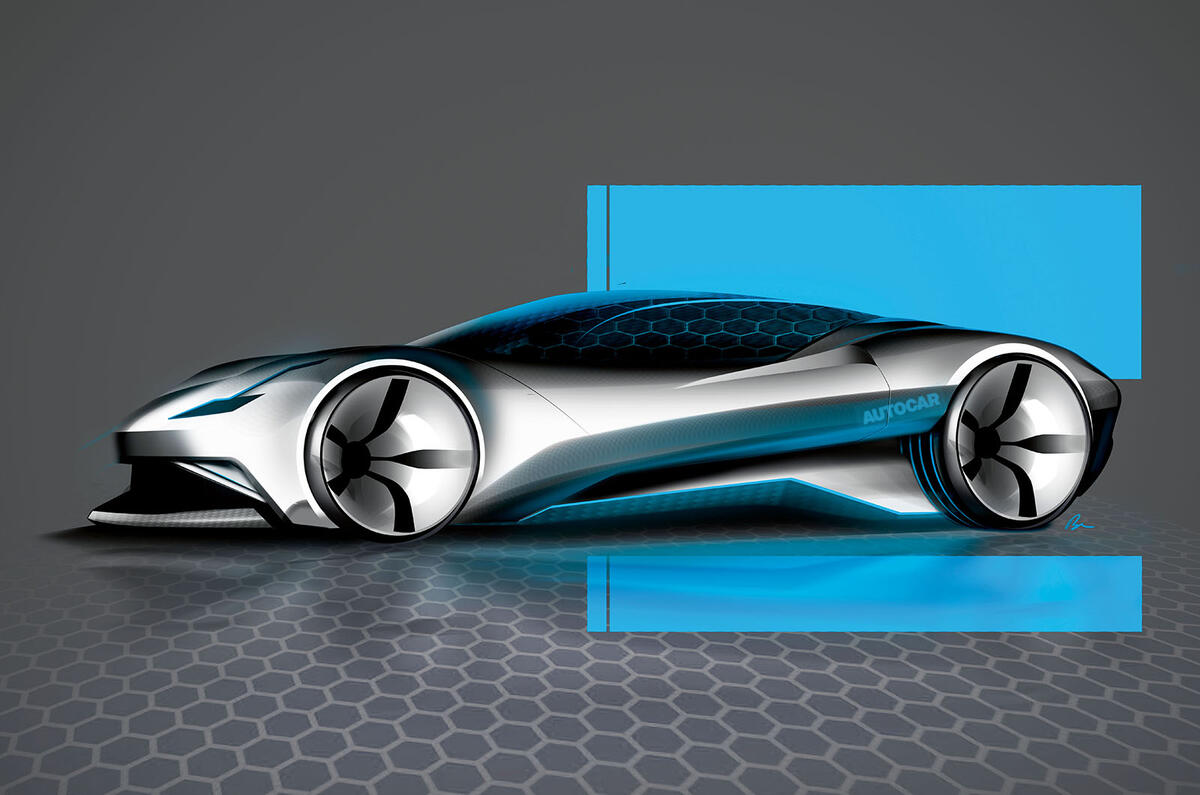

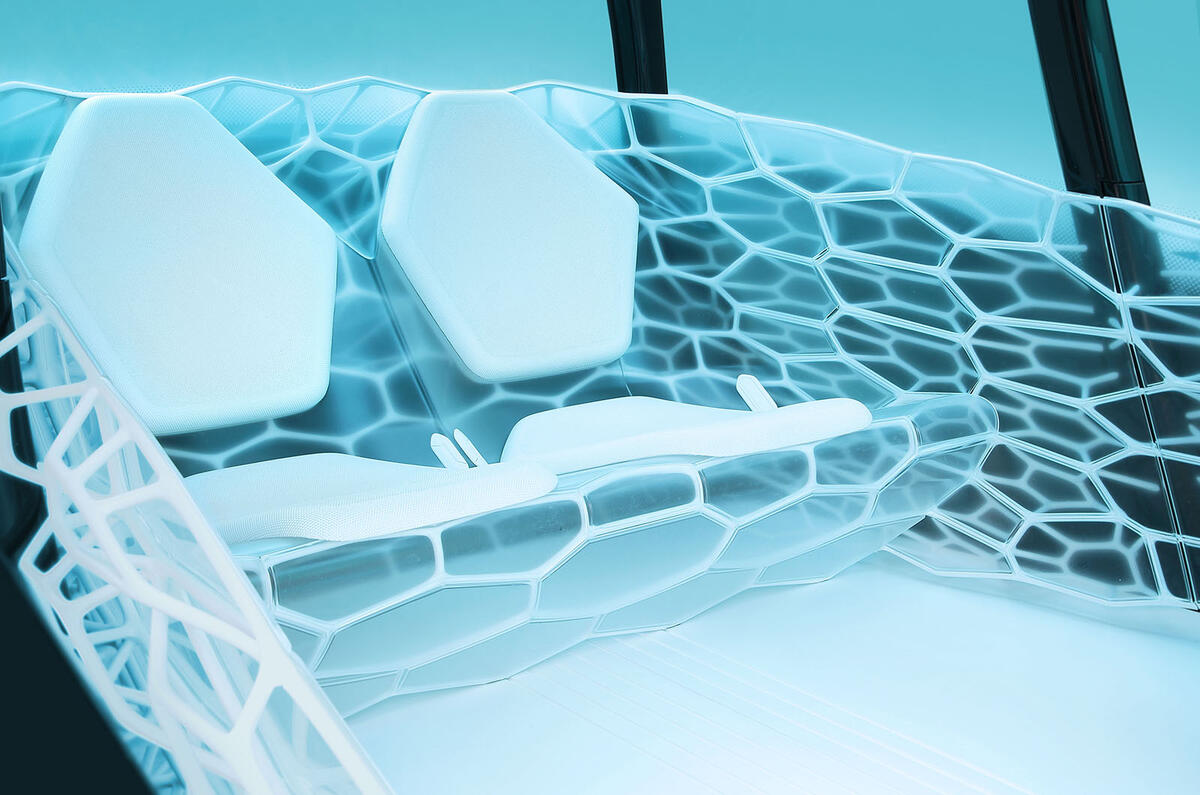

So although the sports car of the future might look a little different from today’s – perhaps it could be similar to our artist’s impression on this page – and might be packed with the kind of technology that is only now appearing on the radar of manufacturers’ R&D teams, we’re laying our cards on the table and saying there will still be a time and place for driver engagement in 2040.

It might only be on a track day or a desolate stretch of the B4425, but the motor car’s powerful ability to excite, entertain and engage won’t be altogether confined to the history books. Truth be told, gauging the direction of the car industry is a challenge rendered nigh on impossible by the sheer pace and intensity of change and development.

We’ve had a good go, but if you have your own vision of the future, or disagree with us, we’d love to hear about it in the comments section below (or via mind meld).

What sort of engine will my car have?

As we move closer to 2040, “the majority of cars will be electrified in some way and the engine may no longer be the primary drive; its role would be to support an electric motor”, says Ricardo’s chief technical and innovation officer, Neville Jackson. In that case, the engine is likely to be smaller, highly boosted by turbocharger or an electrical boost system and redefine the idea of high efficiency.

Today, only about 20-30% of the fuel burned in an engine is converted to power and Ricardo has many ideas for devices to recover heat energy that is normally wasted through the exhaust and cooling system. One idea is to use it to drive a small Stirling engine (originally invented in 1816 as a rival to the steam engine).

The Stirling engine relies on an external heat source to develop mechanical energy, which in this case would be fed back into the driveline. Another idea is to use thermo-electric materials, turning heat into electricity to help power the electric traction motor of a hybrid.

An engine of 2040 might not be the four-stroke engine all cars use today. It may, for example, be a split-cycle engine where cylinders work in pairs, one for intake and compression, the other for power and exhaust.

Alternatively, engines may become a hybrid between a petrol and a diesel engine, switching between spark and compression ignition and possibly burning a future cocktail of fossil and synthetic fuel. “The technical opportunities are immense,” says Jackson, “and for the average motorist, cars will just get better and more efficient.”

Will hydrogen power take off?

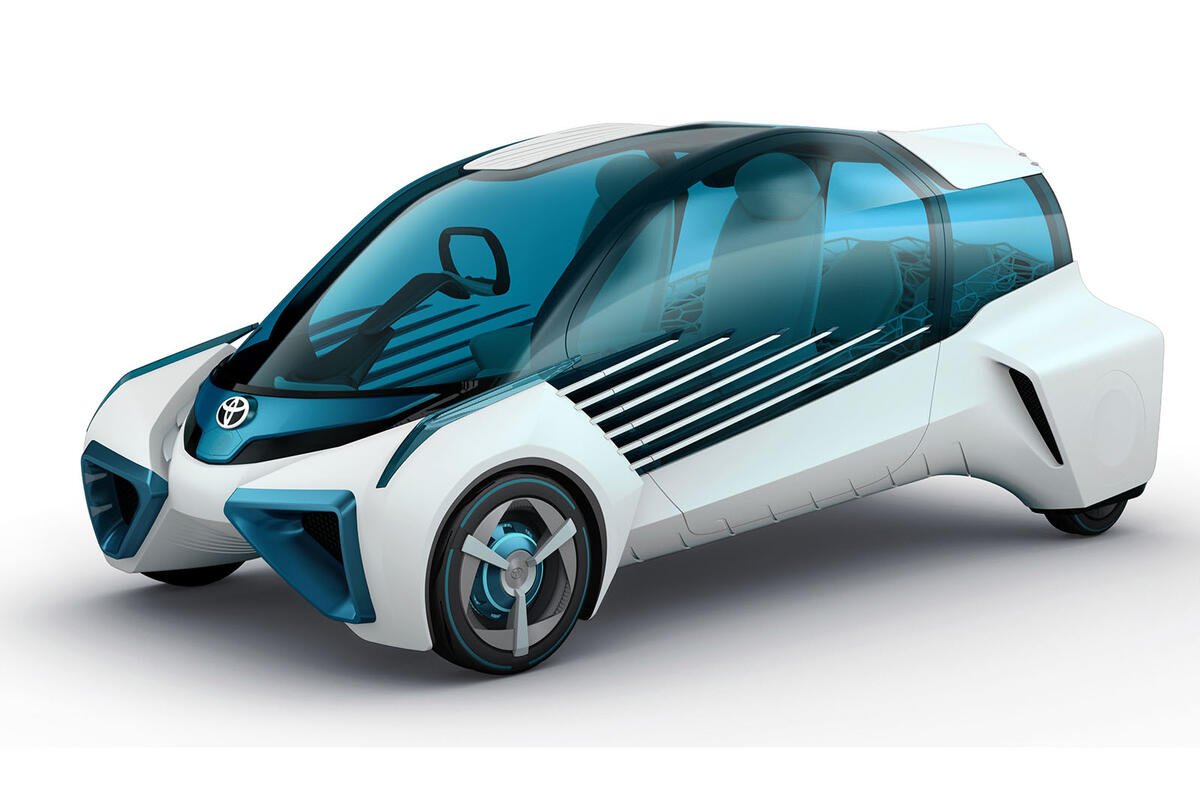

For almost two decades, the world has been tantalised by the idea of hydrogen fuel cell electric vehicles (FCEVs), with ample range and no tailpipe emissions except water and heat. Now the chances of the hydrogen fuel cell car gaining a major foothold by 2040 are improving.

“If the hydrogen infrastructure business model works and the car manufacturers become serious, there could be a significant ramp-up after 2020. You could be looking at millions to tens of millions of cars by 2040,” says David Hart of sustainable energy consultant E4Tech and former head of fuel cells at Imperial College.

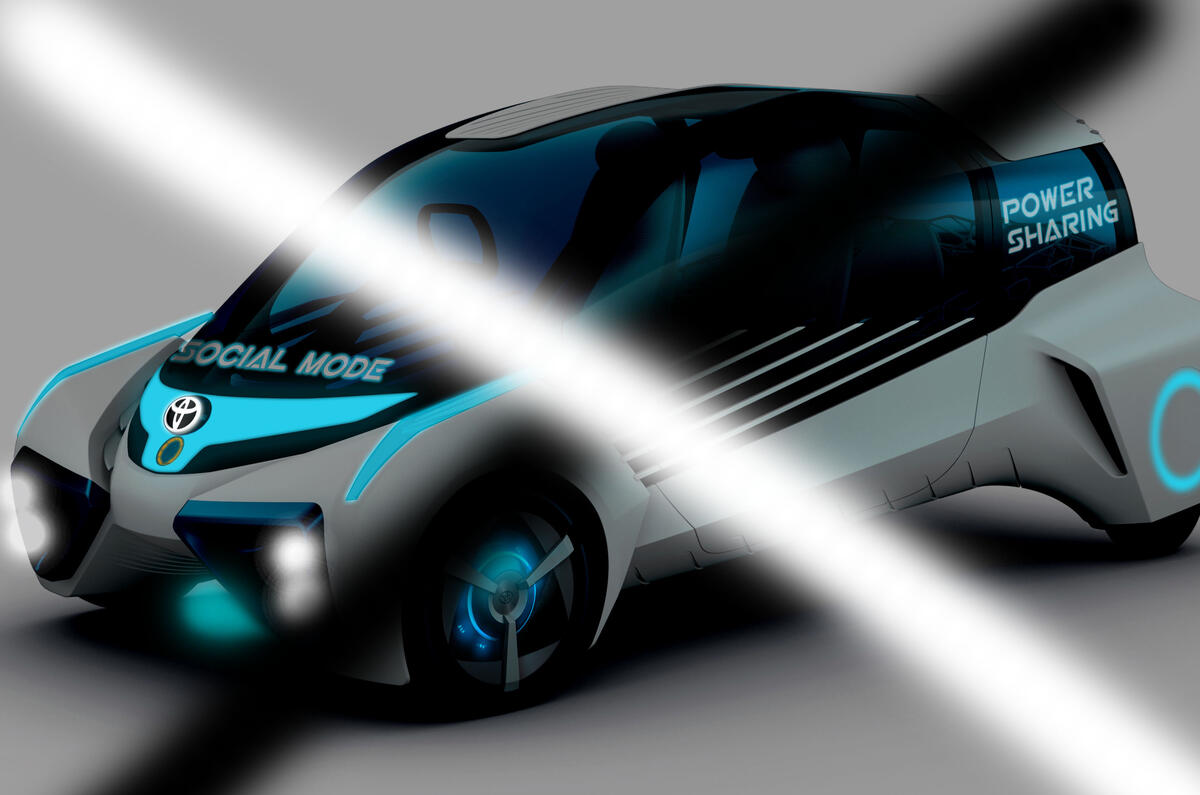

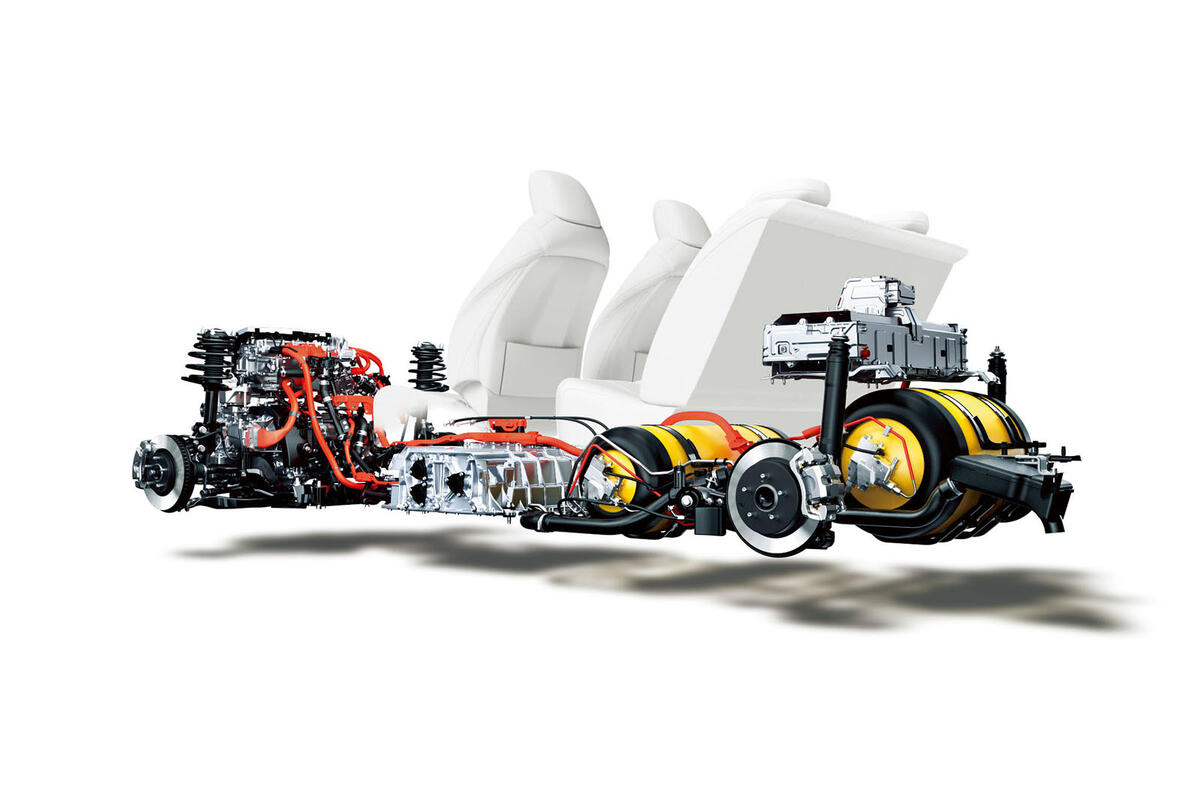

Hart rates the leaders in the field as Toyota, Honda and Hyundai. Toyota’s Toyota Mirai has the same “skeleton” as Toyota’s hybrid models, but what’s different is the power source, says Toyota fuel cell specialist, Julien Roussel. A hydrogen fuel cell feeds electricity to a buffer battery, which provides the transient response to the accelerator pedal for acceleration and stores electrical energy recovered by regenerative braking. “This is the ultimate evolution of our core hybrid technology,” Roussel explains.

A fuel cell ‘stack’ contains hundreds of the small individual cells converting compressed hydrogen and airborne oxygen into electricity, with only heat and water as by-products. Hydrogen is stored in carbonfibre tanks at a pressure of 700bar. Manufacturing both was once labour-intensive, but Toyota has reduced manufacturing costs by introducing automation and producing everything, including the carbonfibre hydrogen tanks, in-house.

The energy density of hydrogen storage on board is around five times higher than that of today’s battery technology by weight and the Honda FCV Clarity introduced last year has a range of 435 miles on one fill. Refuelling time is equivalent to that of petrol or diesel and hydrogen fuel is at least as safe to use as the other two.

Building an infrastructure of hydrogen filling stations remains a challenge to the large-scale adoption of FCEVs. By the end of 2016, there should be around 200 hydrogen filling stations globally. “A hydrogen infrastructure is difficult to scale up, but once it’s there, it’s a profitable business in its own right,” says GM fuel cell expert Ritmar von Helmolt. “Recharging stations for electric vehicles are not, because the cost of operating them is significantly more than the cost of the energy being sold.”

There’s plenty of global investment. In Europe, £1 billion has been budgeted to support hydrogen and fuel cell development from 2014 to 2020.

Will I still be putting petrol or diesel in my car?

Fifteen years ago, the oil industry warned that oil could become uncomfortably expensive to extract by 2040 and that some oil-producing areas could begin to dry up. Today, the story has changed.

According to BP, fossil fuels are going to become cheaper and easier to extract. Between now and 2050, BP estimates there are 4.8 trillion barrels of ‘oil equivalent’ energy (oil and gas) that can be recovered using today’s technology and the projected demand to 2050 is 2.5 trillion barrels. A further 2.7 trillion could be available through new discoveries and improved technology.

BP is less optimistic about the uptake of radical new technologies such as the hydrogen fuel cell and thinks the global energy demand for transport until 2035 and beyond is likely to be met largely by liquid fuels.

Some alternatives can compete with oil on cost, though, such as Brazilian sugar cane ethanol and synthetic liquid fuel made from natural gas using the Fischer-Tropsch gas-to-liquids technology. The report also says that by 2050, biomass could sustainably match the amount of energy produced from oil through careful selection of land, crop management and the use of crops such as the fast-growing grass Miscanthus.

What sort of tyres will my car have?

Tyres are already an integral part of a car’s performance today, but they will have an even bigger role to play by 2040. “The trend for 2040 is for cars to be connected. Interest is growing in using big data by connecting vehicles so they can communicate information about road conditions,” explains Goodyear’s director of technology programmes, Romain Hansen.

The first stage will be connecting tyres wirelessly to the vehicle to improve safety. “If the vehicle knows the composition of the tyre and how it performs, the ABS system can reduce stopping distances in all conditions,” says Hansen.

Once that stage is reached, cars will be able to share information about the road surface condition and temperature with other vehicles via vehicle-to-vehicle connectivity (V2V). Adaptive tyres demonstrated by Goodyear’s TripleTube concept will change shape according to road conditions and use. In the wet, the pressure will increase to produce a longer contact patch better able to resist aquaplaning.

The use of thermo-electric materials will convert heat energy otherwise lost when the tyre deforms in use to electricity. Piezo electric chips embedded in the tyre’s sidewall will also recover energy normally lost when the bottom of the tyre deforms as it rolls. Rice husk ash, which normally goes to landfill, is rich in silica and is typical of new materials that will be used to make tyres more sustainable.

Will my EV’s range have improved?

The major stumbling blocks of any battery electric car are range and the time it takes to recharge. By 2040, things could look very different, with battery electric cars capable of driving up to 500 miles on a single charge and taking a 75% charge in as little as 15 minutes.

The race is on to develop lighter, cheaper, more sustainable batteries with much higher energy storage capability (energy density). A typical EV battery today has an energy density of 30kWh, giving an average range of around 100 miles. By the end of the decade, Bosch aims to have a second-generation 60kWh solid-state battery capable of delivering a range of more than 200 miles.

Today, not all lithium ion batteries are chemically the same and are made from a variety of chemical cocktails. Those with the highest energy density (giving the longest range) use cobalt in their chemistry, but there’s a catch. “Cobalt is a rare metal available from a few mines in the world,” says Joachim Fetzer, head of petrol engines and electromobility at Bosch.

A third-generation lithium sulphur battery is expected to solve those problems by 2030. This oddly named ‘post-lithium’ technology will be safe and light and have twice the energy density (128kWh) of a second-gen battery of the same weight.

This should give a car the size of the recently unveiled Chevrolet Bolt a range of around 400 miles.

Who, or what, will be driving my car?

Will we be driving the cars of the future or will they be driving us? Probably a bit of both and all major manufacturers are working on self-driving cars today. Autonomous technology isn’t new. It has been creeping up on us for two decades, says Tony Harper, head of research at Jaguar Land Rover. “We are on a trajectory that began with radar, adaptive cruise control, then blind spot monitoring, which moved radar to the sides of the car, and now there are forward-facing cameras.”

The next stage is sensor integration and further development of software algorithms. “By 2020, we’ll see parking functions joined by low-speed manoeuvring in traffic jams and some high-speed driving, like lane changing, will become automated,” says Harper.

Beyond 2020, more complex sensors such as lidar will be needed and Harper thinks the first production applications of full autonomy will be “short-range missions”, like fully autonomous valet parking and autonomous driving in dedicated lanes of motorways. The number of zones will grow as the infrastructure is developed to accept autonomous vehicles, but eventually, says Harper, “restrictions will drop off one by one until we get to full autonomy. No one knows exactly when that will be, but the journey will start by 2025.”

So by 2040, will cars be completely self-driving or will the driver still have a choice? Harper says: “We believe cars are there to be driven, but there are lots of situations where we might choose autonomy, from summoning a car to you, to taking over on a boring journey and increasing your productivity.”

Special training won’t be needed to use an autonomous car, in Harper’s view. “If someone needs training to use an autonomous feature,” he explains, “then you’ve got the autonomous feature wrong. It should do what you expect it to do.” It should not be a big step for a driver to submit to the car taking control, either. “One of the things the car can do is assess the ‘threat’ level and decide whether it’s safe to go into autonomous mode or not.”

The three-year, £19.2 million UK-Autodrive is just one project, of which Jaguar Land Rover is a member, designed to test these theories before fully autonomous cars appear on the roads.

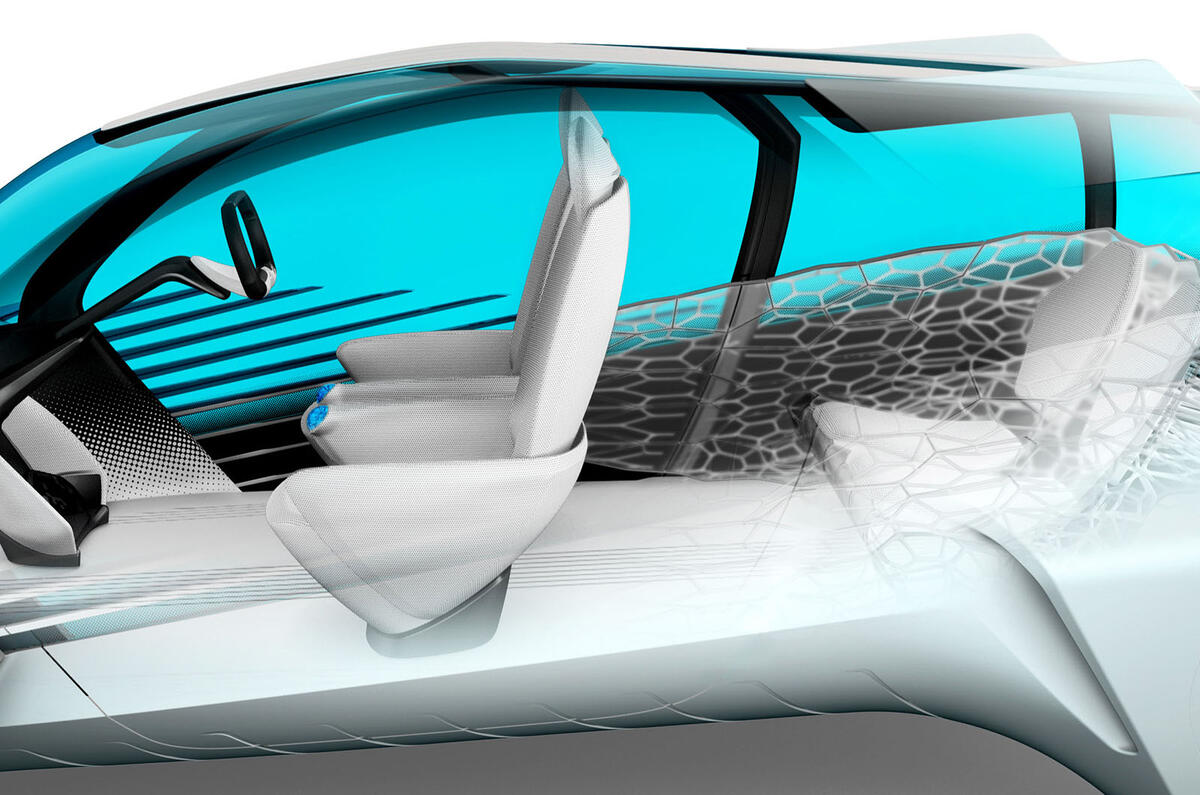

What will car interiors look like?

We’ve already got digital instrument clusters and digital infotainment screens, but melding the two together to create one, unblemished surface is seen as the next step in creating the next-generation car interior.

BMW has already previewed its own future cabin, which includes a large screen running almost the full width of the cabin. The system is fully prepared for autonomous driving, allowing drivers to take video phone calls when the car is in self-driving mode and showcasing content from the firm’s Open Mobility Cloud when the driver enters the car.

The next step is to allow drivers to personalise the cabin, choosing themes for the dashboard and even downloading different dial styles for the instrument cluster. Early versions of this personalisation are already available, with Mercedes-Benz pre-loading the new E-Class with three themes that change the look and content of the instrument cluster and infotainment system.

In the more immediate future, expect far more cars to come with digitised instrument panels. As Audi has shown, the technology can be quickly adopted into new vehicles and in time will become cheaper to fit than standard analogue dials.

Won’t these high-tech interiors distract me?

Haptic feedback isn’t new technology in itself – it already features in cars such as the Lexus NX – but it’s all designed to help keep drivers’ eyes on the road, rather than on the infotainment display.

Bosch is taking the system to the next level. Its take on haptic feedback is capable of replicating the feeling of real buttons on a flat surface, and drivers ‘push’ down on the surface to activate various functions. The system can recognise the amount of pressure applied to the surface, resulting in different functions. A light touch might open a help menu, for example, whereas a more firm touch would activate the e-call system.

Even pressing a touchscreen could become old-fashioned. The next step in infotainment systems will be gesture control. Your movements will be tracked by internal cameras, so the car knows who is asking for the volume or temperature to be turned up, and where. Beyond that, the technology also allows cars to recognise when drivers are approaching and open the door automatically for them.

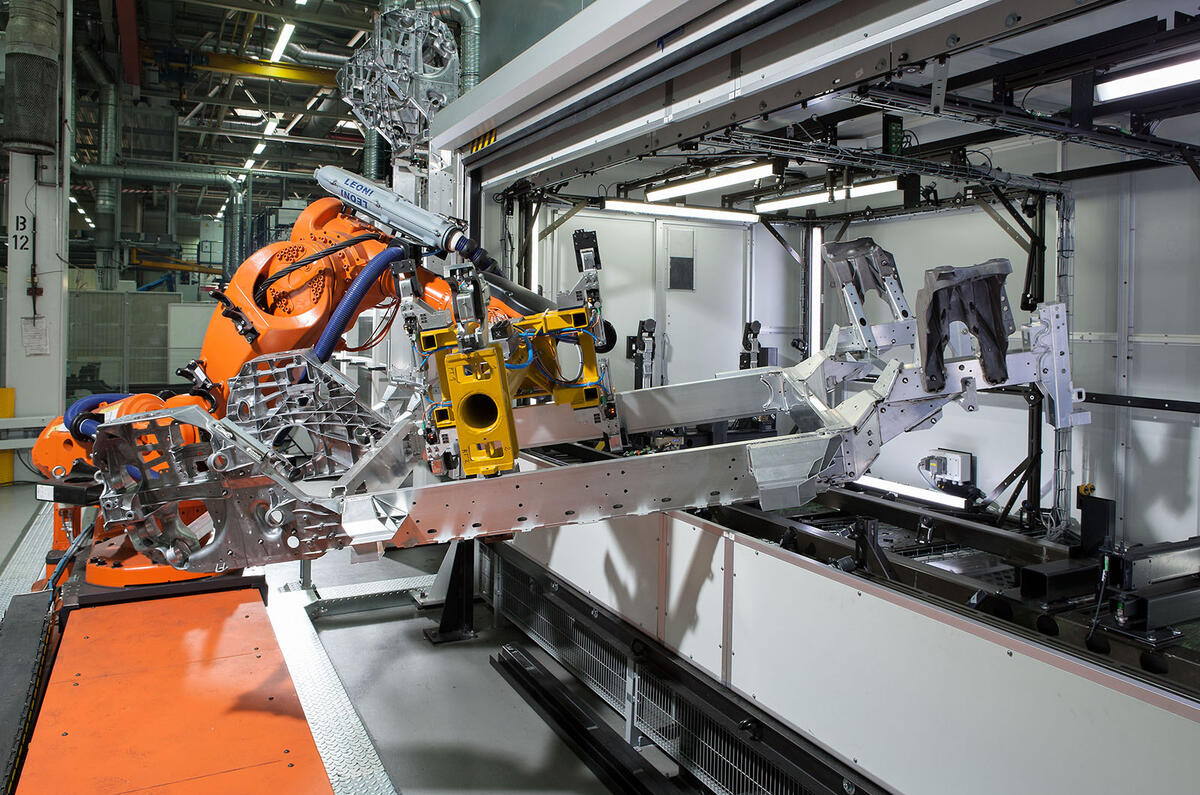

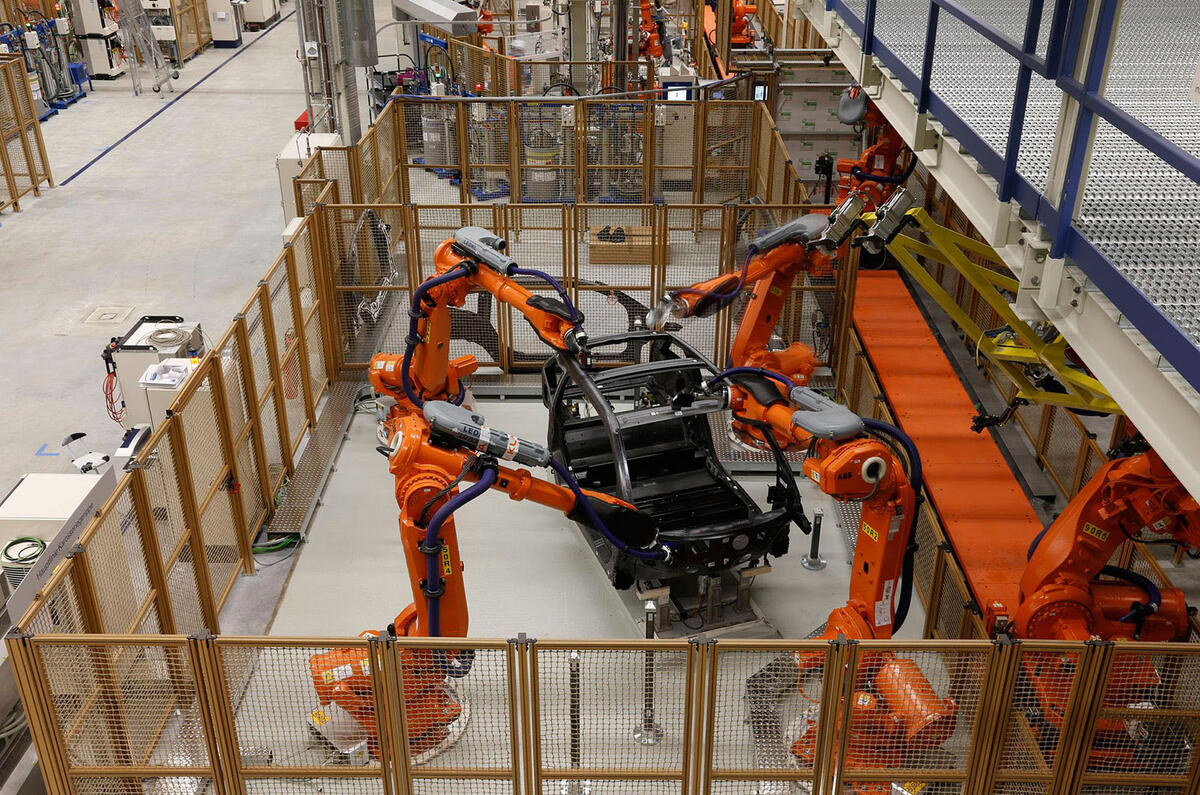

How will cars be made in the future?

We’ll certainly still have production lines and component deliveries will still be made to the line-side ‘just in time’ by component makers, whose factories are situated close by. However, thereare two things that car makers would like to be able to achieve on conventional production lines that haven’t yet been cracked.

One is the ability to build cars with individual specifications much more quickly and efficiently, because at the moment a car specified by a private buyer can take up to 12 weeks from the showroom order to final delivery. The other thing that manufacturers are chasing is the ability to efficiently reduce capacity during a sales downturn.

This is why Toyota’s attempt to reinvent the car factory and the conventional production line looks like it could be the future for car manufacturing. As you might expect from the company that led the world in lean manufacturing in the 1980s and 1990s, Toyota has gone right back to basics.

After Toyota’s sales were badly hit by both the 2009 global financial crash and the great Japan earthquake in 2011, the company froze investments in new factories and decided to rethink the conventional production line. The result is a new way of building factories and installing line-side equipment.

Firstly, Toyota no longer uses overhead production lines. This allows the new factory building to be simpler and less expensive to build, light and heat.

Secondly, the production line is built like a model railway track, sitting directly on the factory floor and being clipped together in sections. This allows a line to be shortened or extended in a matter of hours. The line-side equipment that helps production line workers pick up and mount heavy sub-assemblies, such as dashboards and seats, has been re-engineered by the company’s own engineers.

This equipment will be lighter, simpler and moveable, rather than fixed in position.

The upshot is that if Toyota decides to add a new feature to a vehicle, the production line can be extended and a new work station added in a matter of hours.

Moreover, Toyota’s reinvention of the production line will also allow individually specified cars to be built as part of production runs. For example, Toyota engineers have designed a radically down-sized plastic slush moulding machine, so if a customer orders the more expensive dashboard finish, it can be created line-side in seconds. There’s even a line-side sewing machine that can be used to create a stitched finish for the dashboard moulding. Only the body welding remains highly automated in the new-age Toyota factory.

In tough times, Toyota can shorten or even mothball this new production line and the line-side equipment, potentially completely clearing a whole production hall, which can then be shut down.

Toyota’s new production system will be phased in with each new factory that it builds, so the company should have switched to the new system by 2035 or so.

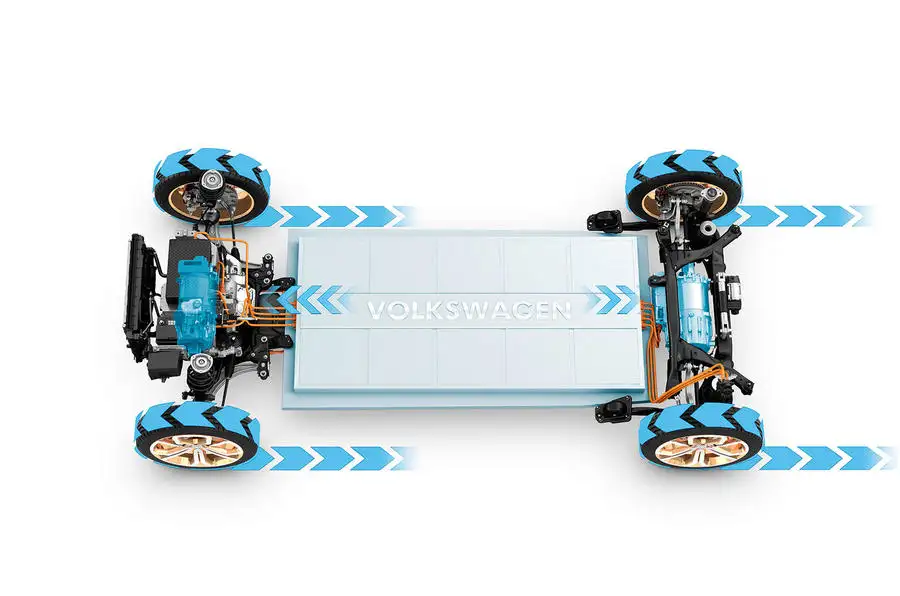

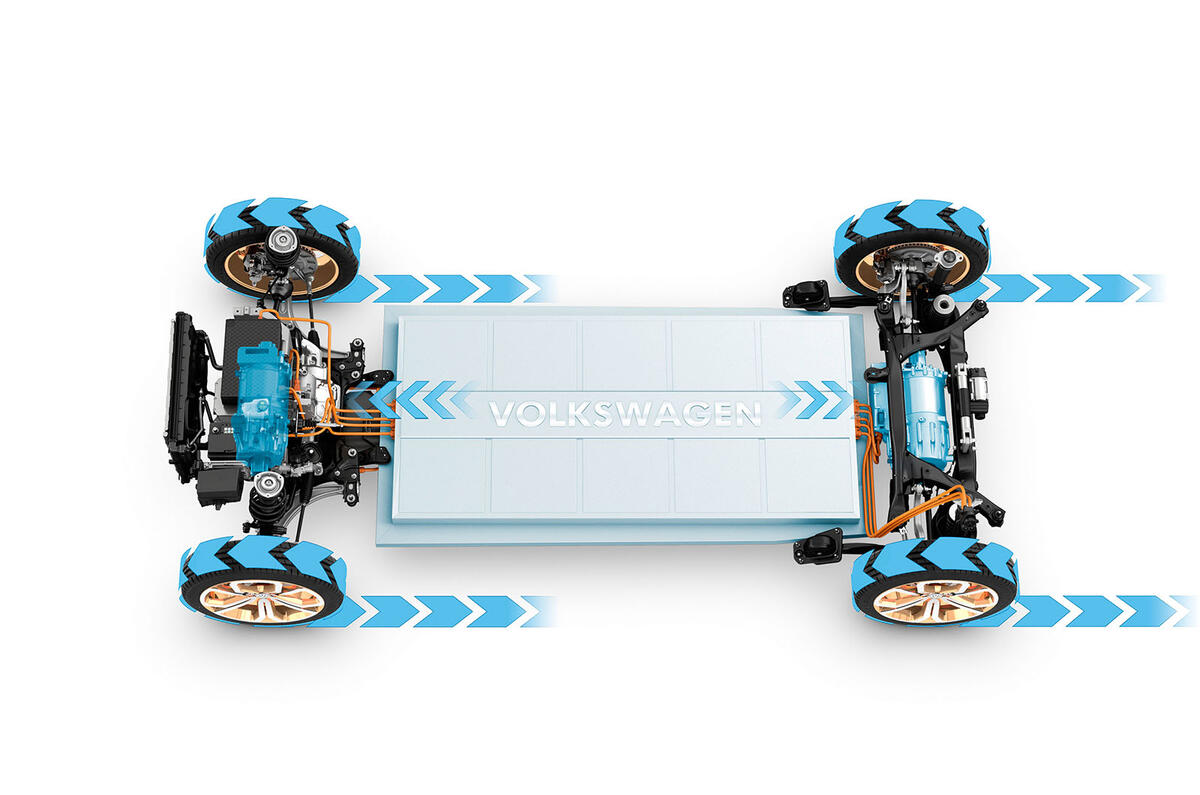

However, there is one other future scenario for car production. If vehicles powered primarily by electric motors become the norm, car makers could be reduced to operations that just produce bespoke upper bodies and interiors.

That’s because electric motors and battery packs would become commodity items (like computer chips) bought in from outside suppliers. ‘Skateboard’ chassis that simply vary in length and width, as used by Tesla, could also be sourced externally.

Such a future would necessarily simplify conventional car factories as the running gear becomes generic and the car makers put more effort into vehicle design and anything that makes a brand more distinctive.

What will my car be made of?

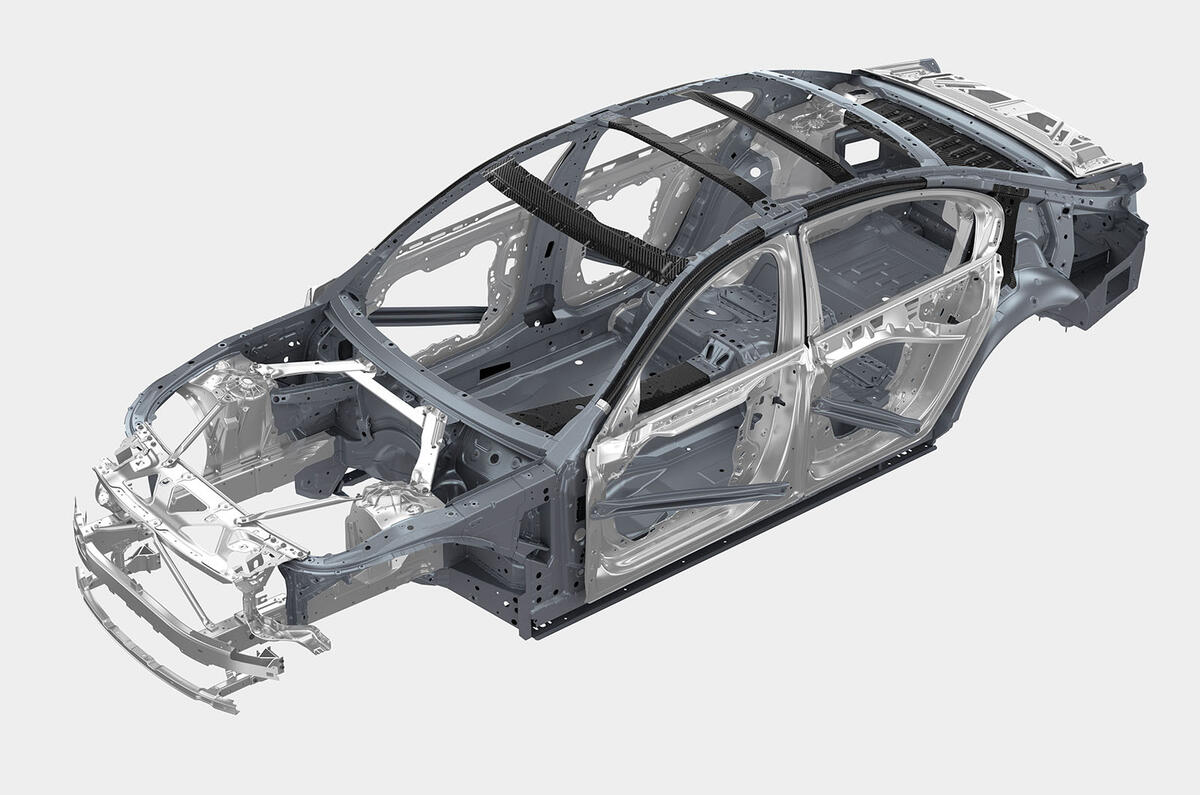

Twenty-five years on from the first serious use of carbonfibre in a mainstream production car with the ‘Carbon Core’ of the 2015 BMW 7 Series, cars will be constructed using a wider variety of lightweight materials than today. Even engines and gearboxes could be partially made from plastic in 2040, giving substantial weight savings.

Transmission specialist Drive Systems Design is working on transmission casings, gears and synchronisers made from polymers. “The most highly stressed areas of gears could be given a spray-on metal coating and the less stressed areas made from high-performance plastics,” says managing director Mark Findlay. Plastic components not only weigh less but also absorb vibration and noise.

Solvay, a manufacturer of high-performance polymers, is the leading sponsor of a project called Polimotor 2. “We want to make a fibre-reinforced polymer composite internal combustion engine to demonstrate the potential for lightweighting using plastics,” says Solvay global marketing manager Mark Wright.

Polimotor 2 is the brainchild of Florida-based engineer Matti Holtzberg, who developed and raced his first plastic engine, Polymotor 1, in the 1980s. Polimotor 2 is largely constructed from polymer and composite materials (including the block), with steel and alloy used for key components such as the crank, flywheel, cylinders and combustion chambers.

Lightweight steel, aluminium, carbonfibre, plastics and some bio-materials such as flax are likely to form the main structure of cars in 2040. If the carbonfibre industry is successful in its aims, the price of carbonfibre as a raw material could be more than 80% lower than it is today.

Will connected cities ‘design out’ the car?

The phrase ‘connected city’ has become a favourite of governments and urban planners in recent times. The idea is a simple one: using the internet and interconnection to make big cities operate more efficiently. That could mean simple things like street lighting that shuts down until movement is detected or providing by-the-second information on public transport.

The idea of a city based on the internet and big data is much more easily realised when the city is built from scratch. The biggest project in the UK is called ‘Old Oak and Park Royal’, a big ex-industrial area in the Willesden area of north-west London.

But it’s projects such as this that make car makers nervous. Building a new connected city from scratch could result in private vehicles being completely ‘designed out’ and prevented from driving through these new urban areas.

Audi boss Rupert Stadler brought up this subject with Autocar late last year. He said potential Audi owners were even starting to find it difficult to find parking spaces in city centres.

The move to push private cars out of the city centre is exemplified by what has happened in central London over the past 16 years. Since the creation of Transport for London, the capital has seen road space removal, junction blocking and a significant reduction in on-street parking places that have, in turn, been handed over to car share schemes and a bicycle rental programme. Indeed, a huge scheme to take away significant road space on the capital’s main east-west artery for a major dedicated bicycle lane is currently being completed.

On top of that, air pollution from diesel vehicles is now a major political issue in many European capitals, with threats in Paris to eventually ban diesel power altogether. London has already said it will require all taxis and private hire vehicles to be zero-emissions capable later this decade.

The car of the future – if it wants access to the city centres of the future – will have to have virtually no environmental impact locally, possess the ability to avoid accidents and generally make moderate and gentle progress through built-up areas. Nearly all cars will adopt petrol-electric hybrid transmissions with back-up batteries big enough to allow a city centre to be crossed inzero-emissions mode.

These cars will also have automatic braking, pedestrian and cyclist-detecting cameras and even more sophisticated anti-collision technology. Sat-nav systems will be updated by the second with information collected by other vehicles.

For example, Hyundai’s flagship Genesis G90 has a home-market sat-nav that warns the driver of speed bumps (very useful at night), local speed limits and even the presence of local schools. It also uses aggregated traffic accident information to warn the driver when he is entering a section of road with a higher-than-average history of accidents. Localised weather reports for different areas of the capital, Seoul, are even on offer.

Such information – automatically generated by future vehicles as they drive around – is sent to the cloud and then downloaded to the sat-nav system. Future cars will also be able to connect with traffic lights so the car’s hybrid transmission can calculate whether it is more fuel efficient to shut off the engine and coast to a set of lights that are about to change to red.

More will be needed, though, to safeguard the car’s presence in the cities of the future. Audi is so concerned about the provision of parking that it is sponsoring a project in Boston, the US, that involves the building of compact underground car parks into which autonomous vehicles (remote parking is already a live technology) can self-park.

The car of the future will be heavily influenced by technology that makes it much more friendly to the cities of the future, but we might not have to wait so long for such cars to become mainstream. New models launched in 2020 are likely to be already packed with the technology outlined here. Car makers have to get ahead of social trends and city policy makers. These near-term models will be future-proofed for decades to come.

How will I charge my EV in 25 years’ time?

Electric vehicles and plug-in hybrids will become easier to use thanks to the availability of wireless charging. Instead of plugging in, simply parking the car over a pad will charge the battery.

Wireless charging works by “magnetic resonance”, explains Qualcomm’s Chris Borroni-Bird. “We can operate with gaps up to eight inches. You can think of it in the same way as an opera singer shattering a glass with the voice.” A coil in the charging pad generates an alternating magnetic field in a similar coil mounted underneath the car to generate electricity by electromagnetic induction.

Qualcomm is also developing ‘dynamic’ wireless charging systems with pads installed at intervals below the road surface to charge as you drive.

In 2015, Highways England kicked off an 18-month project to test “dynamic wire transfer technologies” off road. Some experts suggest the cost of installing charge-as-you-drive equipment could be ruled out as a 2040 vision, especially if long-range batteries and hydrogen fuel cell technology take off.

Matt Burt, Jesse Crosse, Hilton Holloway & Darren Moss

Join the debate

Add your comment

Electric Cars

Cant see that electric charging points are viable, they are expensive to set up and people are hogging them already and punch ups have broken out. Couldnt a battery be small enough that you could just slot it in like filling up with petrol. You could go into a "battery station" hire/shop and swap your battery with a charged one. Who wants to hang around waiting for your car to charge up? You could also have a spare battery like you have spare tires

plus 1 for the above

Nice ideas but...