Every November, car industry engineers dig out their thermals and puffer jackets before jumping on a flight to the Arctic Circle for the annual cold-weather-testing pilgrimage.

Autocar readers will know all about this snowy exodus as disguised prototypes get papped as they venture into the open for cold starts, acceleration tests, stability control calibration, anti-lock brake assessment and handling appraisals.

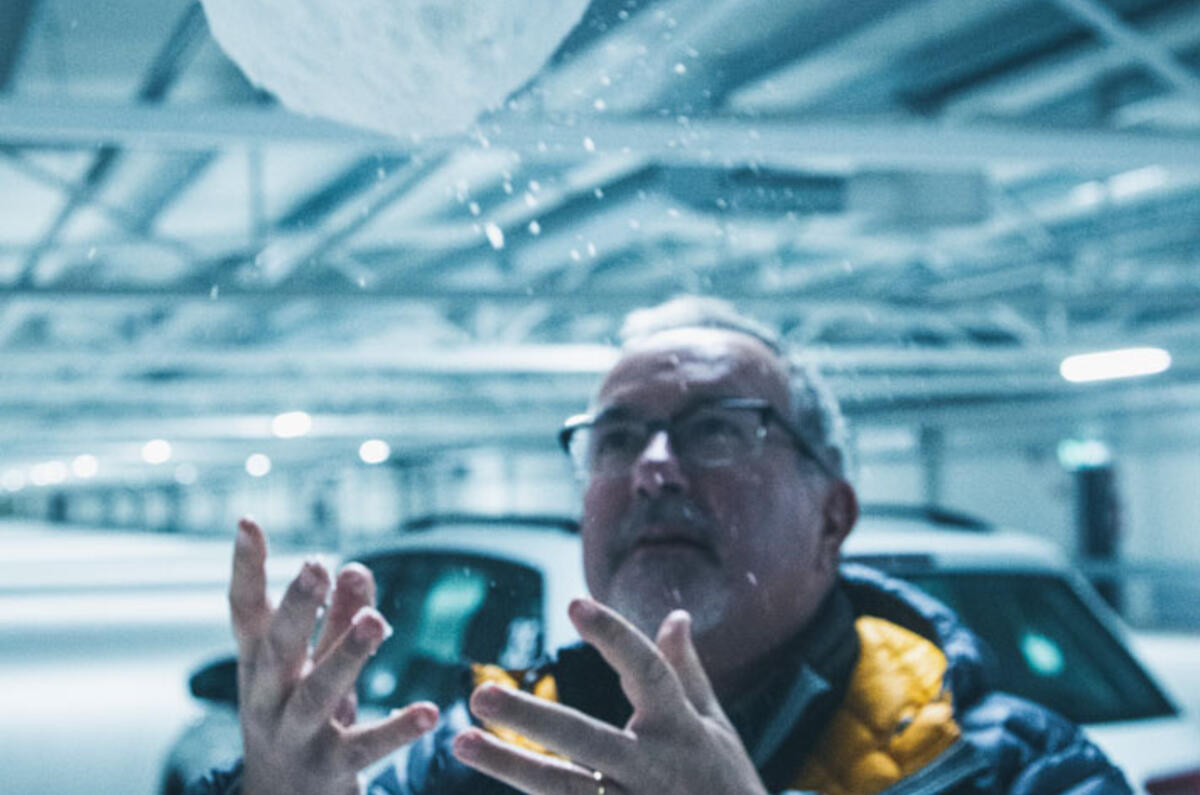

Some engineers, however, have a head start and have been cold-weather testing through the summer months courtesy of an indoor test track where there’s snow and ice despite the outside temperature hitting 30deg C as the sun beats down.

Just one global location offers large-scale indoor cold-weather test tracks – Test World in Ivalo, northern Finland, 180 miles inside the Arctic Circle – and we’ve been invited inside to sample the facility.

“We have test work going on all through the summer – snow tyres, handling, stability control, cold starts, you name it,” says Test World’s managing director, Janne Seurujarvi, “and we are prototype safe, so the paparazzi can’t spy the cars when they’re indoors.”

Test World started out with an outdoor proving ground adjacent to Ivalo’s airport in 1991, and then opened a second site a few miles up the road called Mellatracks, where it built its first indoor track in 2012.

There’s a British link, too. Millbrook, the former General Motors proving ground in Bedfordshire, bought Test World in 2015, a year before Millbrook was itself snapped up by Spectris, the Egham-based maker of precision instruments.

“We have controlled and repeatable conditions indoors because we only use natural snow and that’s very important to engineers,” adds Seurujarvi.

Join the debate

Add your comment

Cool.

Cool.