The absence of a manual gearbox on the latest crop of performance cars has been a growing source of consternation for many who just don’t find any kind of semiautomatic ’box involving enough. The new BMW M3 Competition, for example, isn’t offered with a manual at all in the UK.

Its transmission isn’t a dual-clutch automatic, though. Instead, BMW has reverted to a ZF-supplied eight-speed torque-converter automatic with paddle shifters to gain efficiency.

Since the spectre of CO2 reared its head, manufacturers have worked hard to find compelling alternatives to torque-converter autos back when the nickname ‘slushbox’ was still relevant. Before that, the automated manual (AMT) was the first attempt to take charge of shifting in a way that gave manufacturers some chance of controlling what the engine was doing, efficiency-wise.

Used by Ferrari, Alfa Romeo, BMW and others, they were supposed to offer a glimpse into what it’s like to drive a full-on sequential dog-engagement motorsport ’box without its harshness or self-destructive tendencies.

The emergence of the dual-clutch transmission (DCT) moved the game on and seemed like the last word, vastly improving on AMT and its single clutch by shifting without interrupting the flow of torque. In reality, a perfectly calibrated DCT is so effective in this respect that it can be borderline dull, which is why the imperfection of manual shifting and the skill needed to do it well is still so appealing.

If the DCT appeared to be the perfect answer to combining a race-car-like experience with the efficiency that manufacturers have to chase, even that, it seems, is destined for the outbox.

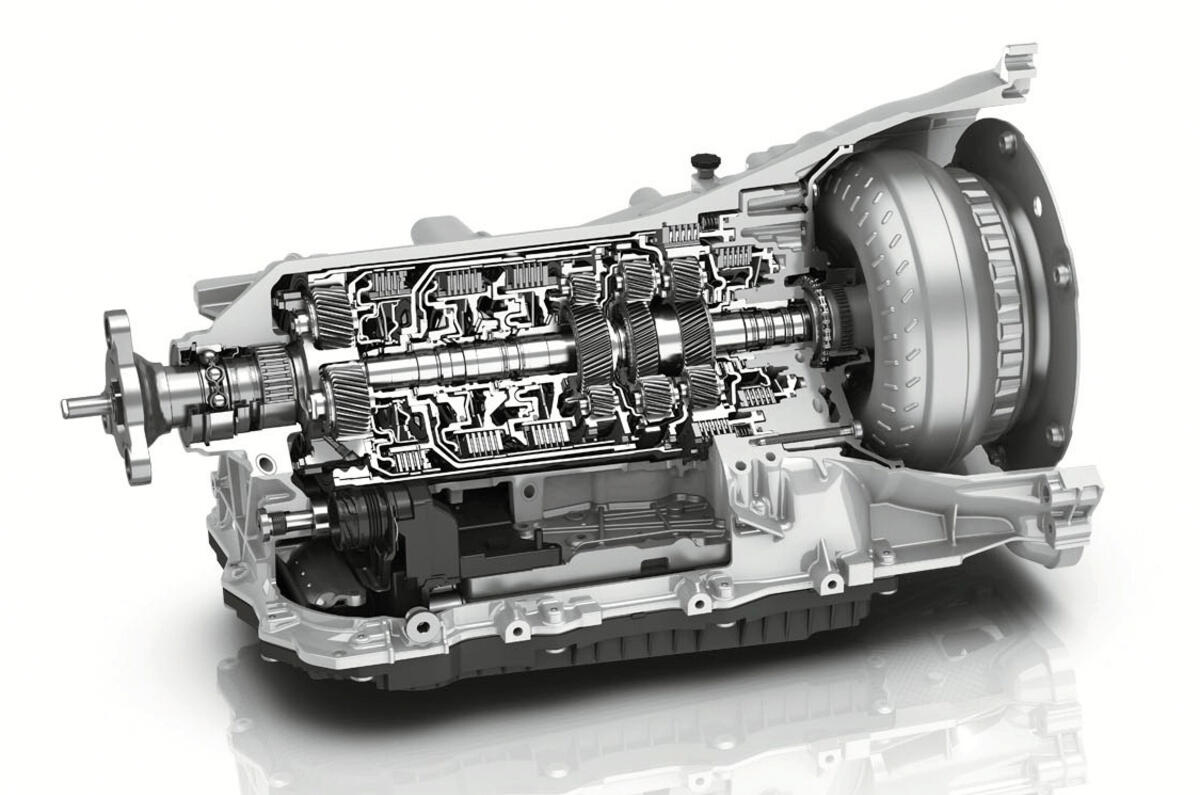

The new M3 is being offered in the UK armed with the ZF 8HP torque-converter automatic, which is now in its third generation and has been steadily developed since its introduction in 2009. Strip away all the internal mechanical differences and the key distinction between it (or any torque-converter-based transmission) and a DCT or manual is that the torque is transmitted from the engine to the gearsets by a fluid coupling, the torque converter, rather than by a clutch or clutches.

The 8HP is a prime example of the modern super-efficient automatic transmission. Internally, the flow of cooling oil can be increased or reduced as needed to save the amount of energy consumed by the cooling pump. The pump supplying pressure for the gearshift actuation system is electrically driven to keep it working while the engine is shut down for longer start/stop and coasting periods.

Most importantly, the minute control over ‘shift point optimisation’ to maximise fuel consumption that it gives engineers is so good that it’s very hard to better it. The 8HP can handle up to 738lb ft ‘input’ torque from the engine, easily accommodating the M3’s 479lb ft. It weighs 87kg – relatively light but still roughly double that of a six-speed manual.

Like it or lump it, though, the choice of automatic transmission technology has gone full circle, from torque converter through AMTs and DCTs and back to torque converter, and that’s unlikely to change now.

Neat tech quickens charge

Continental developed a technology in 2017 that has since stayed largely under the radar. Called Allcharge, it involves making changes to an EV’s inverter, which switches AC current to DC or vice versa, so that it can take over the job of on-board charger.

Join the debate

Add your comment

I suspect the reason has something to do with turbocharging, emissions, the rise of computers to control shift points and dealing with the well proven and understood technology of hydraulics.

Yeah the article doesn't really explain anything:

Here is the actual reasons.

1: Essentially new torque converter gearboxes are dual clutch transmissions. With a planetary gearbox all the gears are connected all the time you switch between the gears by connecting and disconnecting a whole load of clutches.

2: They have lock up clutches the torque converter is not really used other than as a liquid equivilent of a syncro reduce wear on the clutches. The torque converter was once used when you had 3 speeds to allow you to "slip the clutch" in both directions to compensate for you not having enough gears, with 8 or 9 speeds the computer just puts you in the right gear.

3: The 8 speed ZF unit is slightly lighter than an equivilent DCT

4: The shift time is only slightly slower and well within the bounds of acceptability for all but the most focused supercar applications.

No mention of the poor long term reliability of DCTs. Buying a used VAG product with DSG outside a warranty period is a huge gamble.