The challenge to equip a new-generation of British-built electric cars with high-tech batteries also made in the UK has received a £4.8 billion boost from the chemical industry.

A report into the capability of the UK chemical industry to supply essential components – anodes, cathodes and electrolytes – for the cells that will power the next-gen EVs has found a strong network of companies capable of supplying these basic building blocks, already established in the UK.

“The UK boasts some of the largest suppliers of materials to produce cathodes, anodes and electrolytes and is well-placed to capitalise on this,” said the report from the Advanced Propulsion Centre (APC).

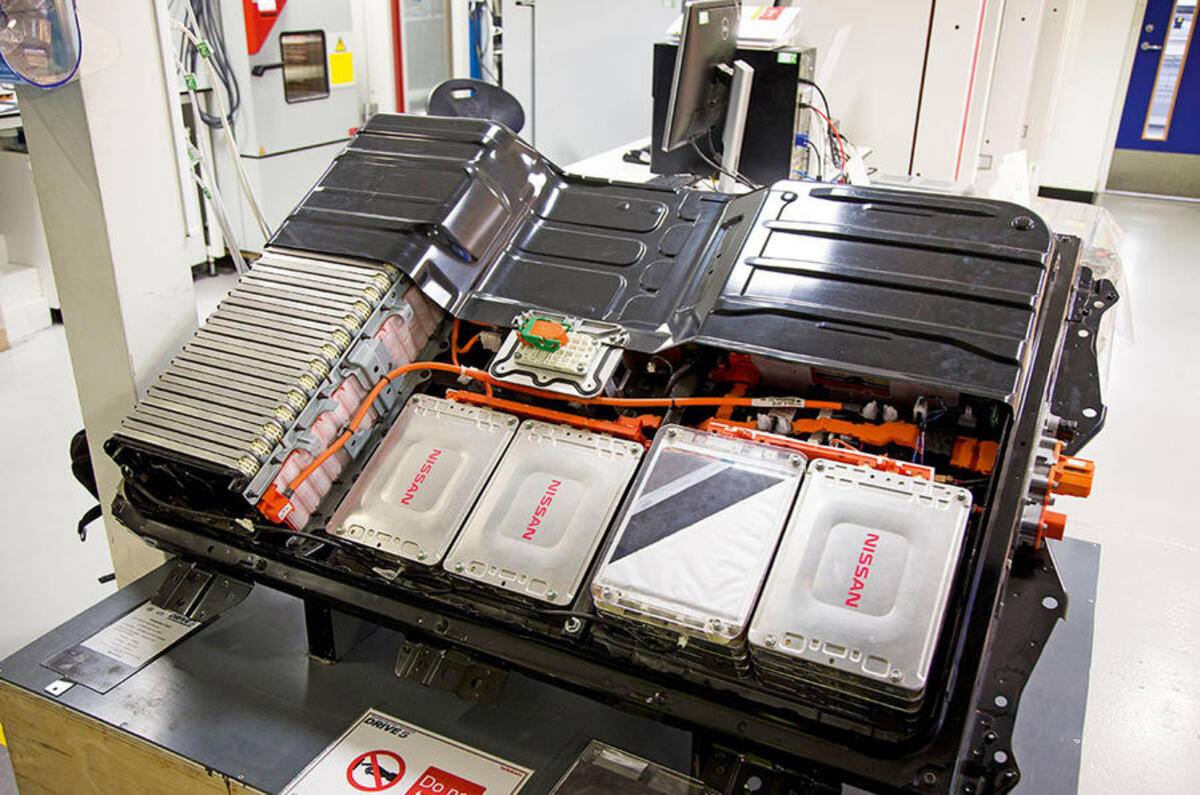

At least three-fifths of the value of a BEV battery pack is in the chemicals and materials, says the report, and a “strong foundation of UK-based companies are already embedded within many global battery supply chains”.

Given the forecast demand for BEVs by 2030 – the date the government has set for up to half of all new car sales to be electrified – the APC estimates that the business could be worth up £4.8 billion a year for UK-built cars alone. Export to European car assembly plants would add further business.

“Today’s report highlights the opportunities available for the automotive and chemical sectors to come together and collaborate to make the UK the go-to place for battery cell manufacturing,” said the head of the APC Ian Constance.

Given that substantial sum of potential business, the APC is stepping up efforts to secure government support to work with suppliers to develop a UK battery supply chain.

Experts are already working on the next-generation of more energy-dense and lightweight batteries, which will require new materials.

“High value opportunities exist for advanced materials supplied in bulk and at very high quality,” said Dave Greenwood, professor advanced propulsion at University of Warwick, “and the supply chain to provide them is in its infancy.”

Government and industry is already working towards a UK battery cell manufacturing facility through the Faraday Challenge, supported with £246m of funding, and the Battery Industrialisation Centre being set-up in Coventry.

“A lot now hangs on receiving clear demand signals in the form of a major battery plant investment in the UK,” said Adam Chase, director of E4tech, a sustainable energy consultancy.

Join the debate

Add your comment

I'm not against nuclear in principle either

But there are more pressing priorities, and spending huge sums on unproven nuclear technology at the present time is not the best option.

Nuclear opt.

Not totally opposed to Nuclear power but I'd like to see a fair chunk go to on more Wind power, afterall it has proved itself.

Note to Government - invest in battery tech instead of nuclear

If the government was to cancel it's investement in Hinkley Point and instead invest the estimated £30 billion in developing battery tech we would dominate the industry for decades.

Just a suggestion.