You might have heard the phrase ‘less is more’. It was one of the rallying calls for the post-war architectural modernists who wanted to chuck out the Victorian chintz and design buildings of extreme simplicity and – often – brutality.

We all know how well that dictum worked out for building, but I’m beginning to believe that it might be an increasingly sensible approach for all non-premium car manufacturers.

I found myself mulling this after my three-day tour of the Dacia operation in Romania.

The first stop on the trip was to the Dacia styling studio in central Bucharest. It’s in one of the corners of the Romanian capital that did not succumb to the concrete tower blocks of the Communist era. A very pretty late 19th-century building, the Dacia design headquarters sits in its own courtyard and used to be the Swiss Embassy.

The design studios are run by Brit Geoff Gardiner, a very talented bloke I used to know a little when he was a post-grad student at London’s Royal College of Art. Gardiner was snapped up by Citroën, had a spell at Ford and was more recently at Renault.

He’s now head of Central European design and head of perceived quality for Renault. There are just 24 designers at the Budapest studio, which opened in 2007, with all large-scale model making and prototyping of parts carried out by an external company nearby.

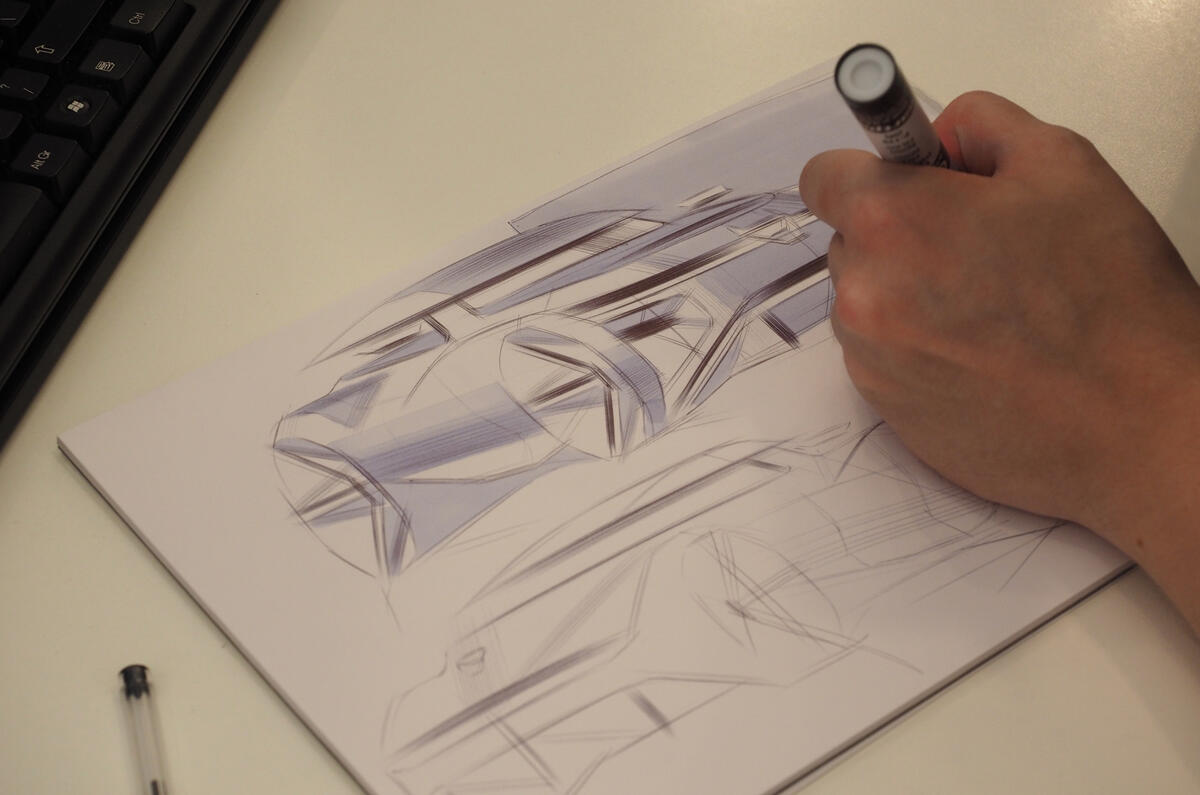

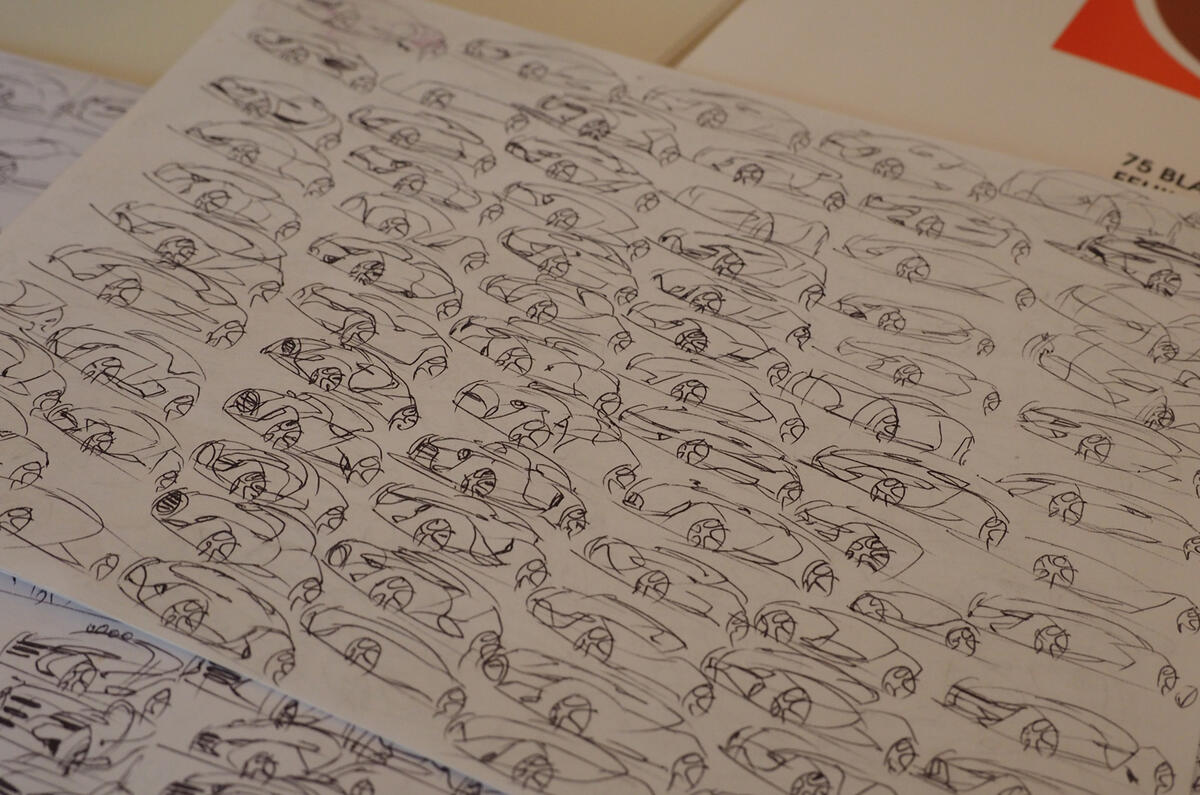

This team is tiny by mainstream industry standards and is further divided down into specific teams. The sketching team does just that: sketch all day, pushing out hundreds and hundreds of ideas. Gardiner insists that all his small team – a mix of people including people from Romania, eastern Europe and India – needs is a ‘black biro and a piece of paper’. And an awful lot of ideas, presumably.

The designers don’t work in 3D, that’s the job of specialist ALIAS 3D modelers who take the best of the designer’s sketches and create them as three-dimensional renderings. Gardiner says that these 3D creations are often animated overnight on the internal computer system as small films. Indeed, as many as 5000 of these mini films are made each year.

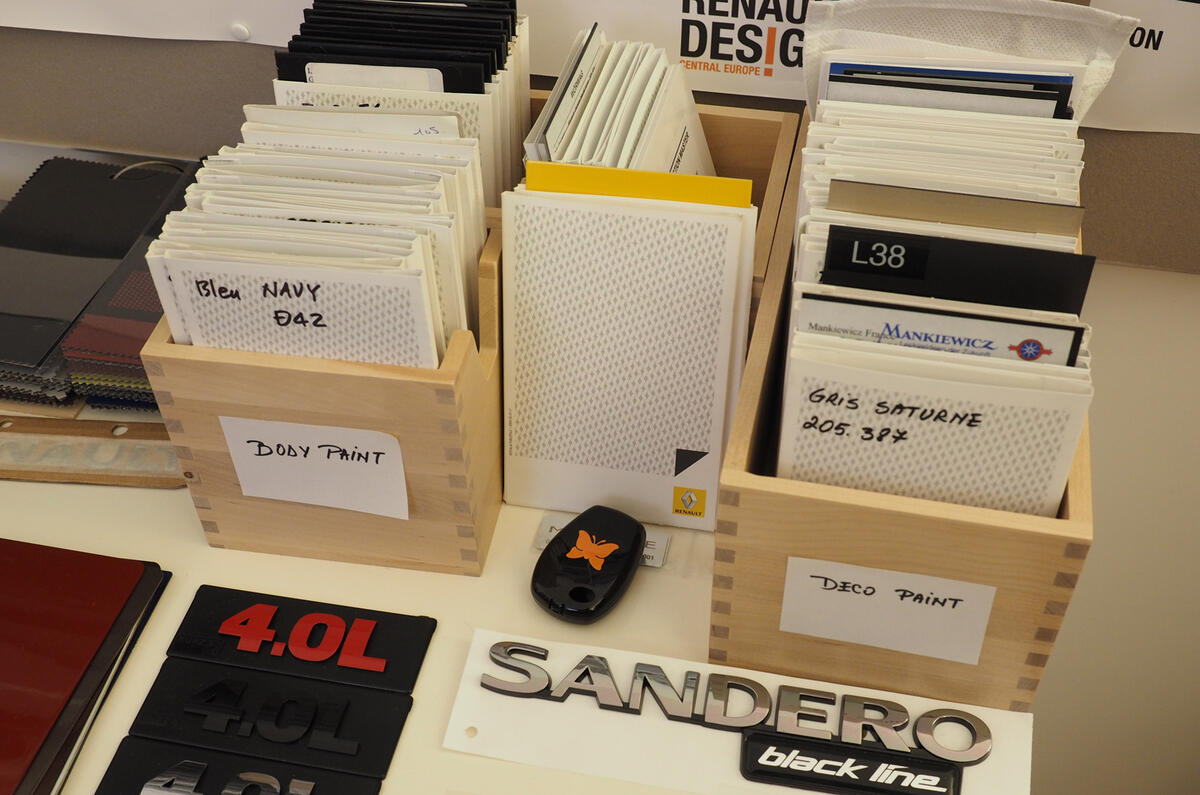

The design HQ also has a small team of people responsible for ‘A-Class surfacing’. These are the specialists who make sure that the surface finish on all the visible parts is as good as possible. There’s also a very small colour and trim team in the building.

The essential simplicity of the Dacia operation extends from this design studio, although the Romanian engineering centre (which optimises the Dacia components set for developing world conditions) to the small components set used to make up its range.

Dacia has one basic platform and will not build more than seven or eight different body styles. By capping engine power for a particular platform, the brakes and suspension components can be downsized and are less expensive to make.

Join the debate

Add your comment

Bucharest not Budapest

Biros...really

Preferred media?