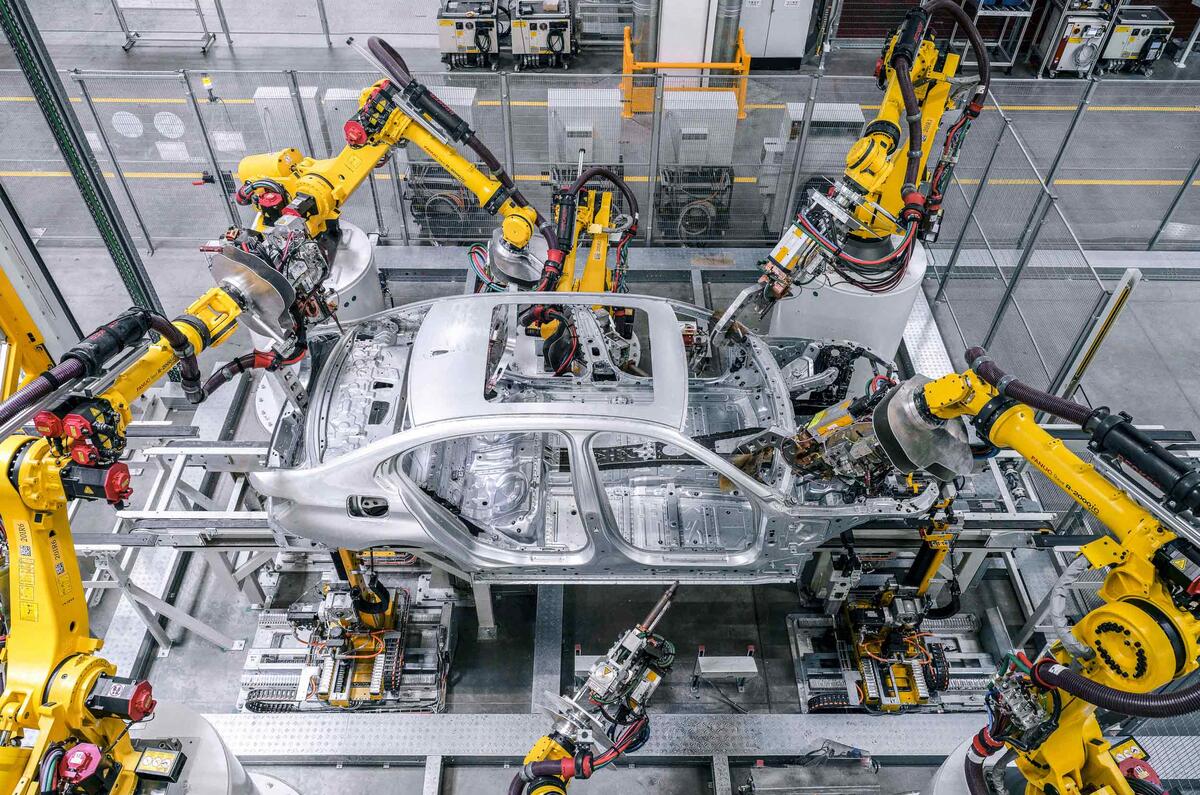

What happened to good old steel? It's been at the core of mainstream cars since the early 20th century, and the Ford Model T was a key catalyst in its industry takeover by the 1930s.

Aluminium and carbonfibre panels higher up the automotive food chain have dimmed some of its lustre in recent years, but incoming recyclability targets may ensure steel has a long, bright future.

World Auto Steel, the automotive arm of the World Steel Association, brings together 18 major global steel producers with the aim of advancing the material to meet the automotive industry's increasingly strict needs "in a sustainable and environmentally responsible way". A big ask, but those leading the way are an exuberant bunch.

"Steel has been around the automotive industry for more than 100 years and has been a primary structural material in the car's history," says technical director George Coates. "It has evolved quite dramatically: just 35 years ago the most common automotive materials had strength levels of around 300 megapascals, while today we have applications at 1900 megapascals."

For those wondering, megapascals measure pressure, and 1900 of them is rather a lot - it's the sort of pressure level generated by high-end scientific instruments.

Stronger, 'ultra-high-tensile' steels are a great way to retain the intrinsic benefits of steel namely its proficiency in crash tests and affordability versus more complex alternatives while stripping some weight, which is a big help when electrification has thus far ballooned the kerb weights of even small cars.

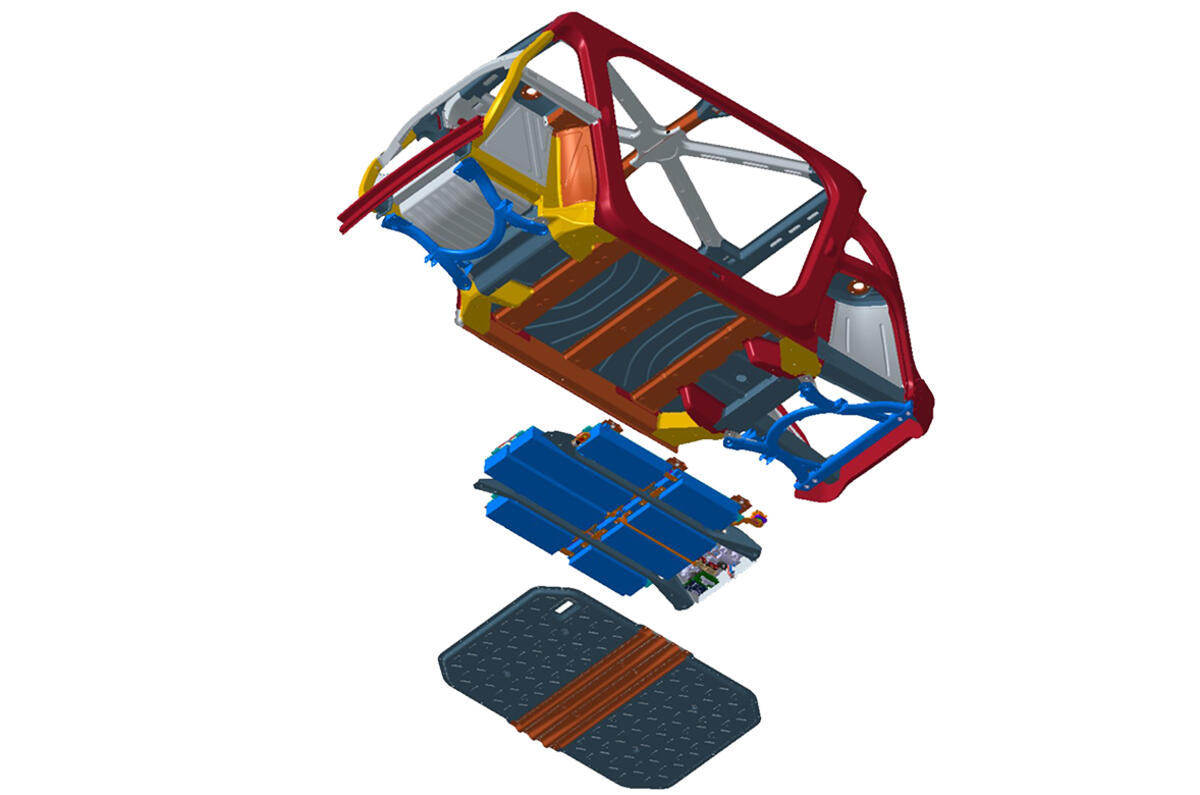

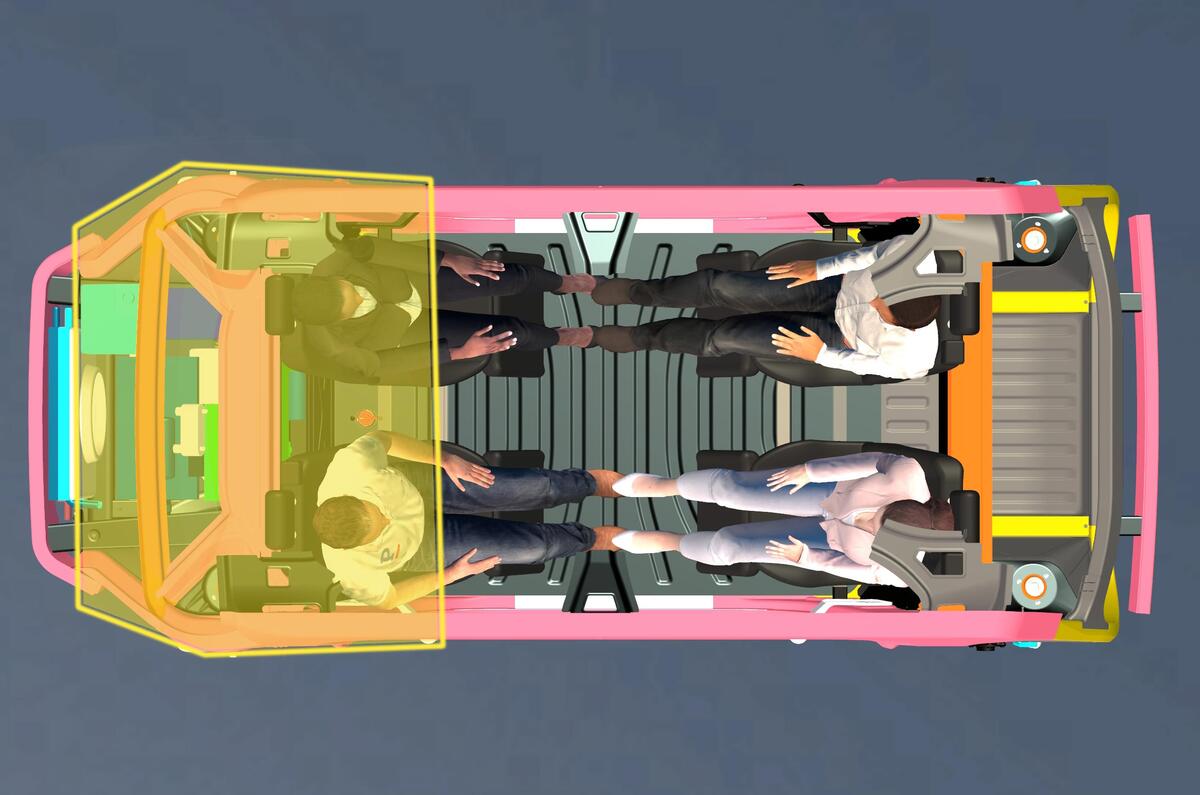

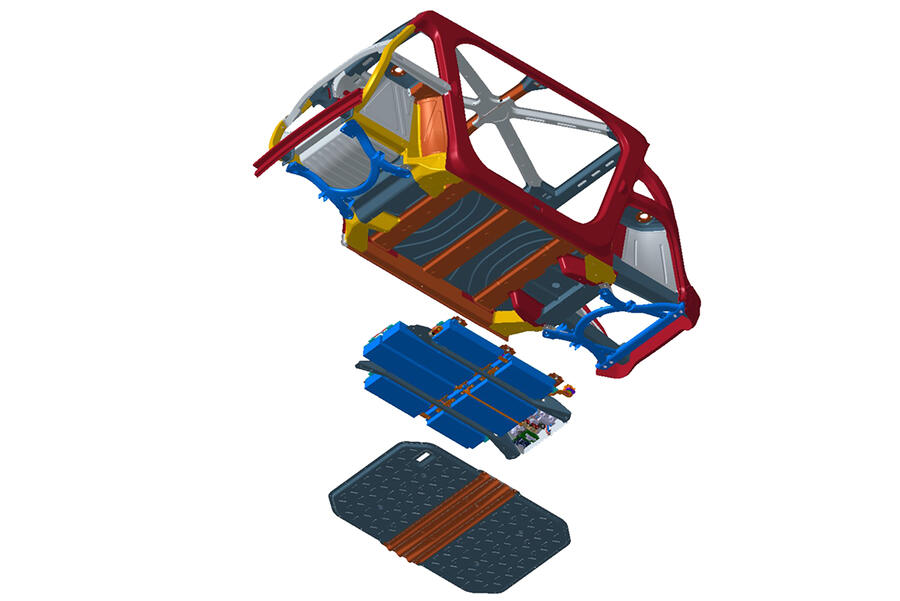

World Auto Steel has partnered Ricardo on a project called Steel E-Motive, a ride-sharing concept that's exploring higher-tensile products to help convince car makers of the benefits.

Add your comment