The turbocharger is so ubiquitous now that even those with no interest in cars to speak of will have at least heard of it.

That's probably partly because these devices are fitted to all manner of engines these days, from 0.9-litre three-cylinders in superminis right up to V12s in supercars, and partly because the word 'turbo' essentially came to mean anything powerful and cool during the 1970s.

Yet this technology has not been in the mainstream for very long. In fact, while the turbocharger was invented way back in 1905 and used on American aircraft during World War II, its first automotive application did not come until 1962.

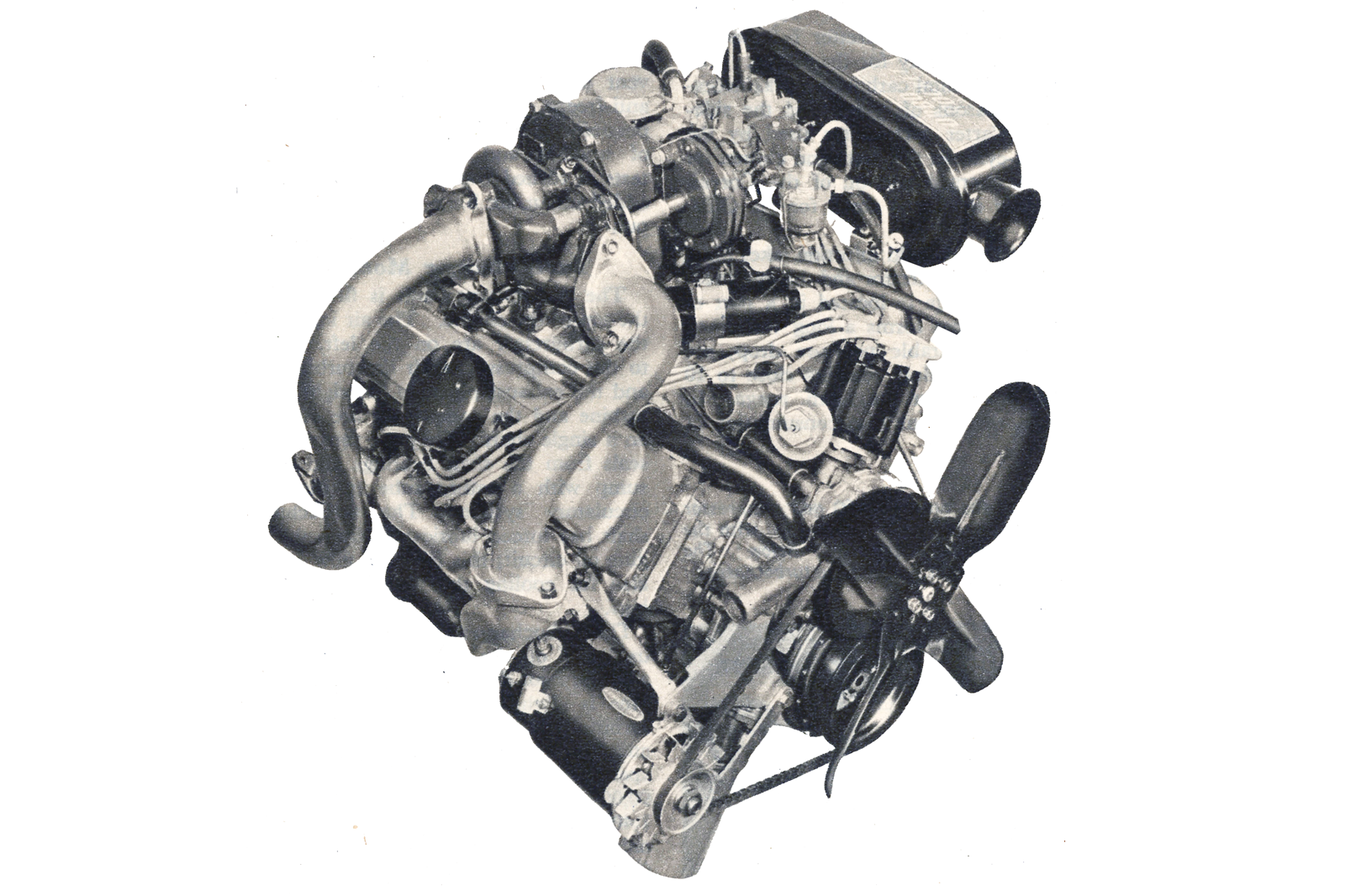

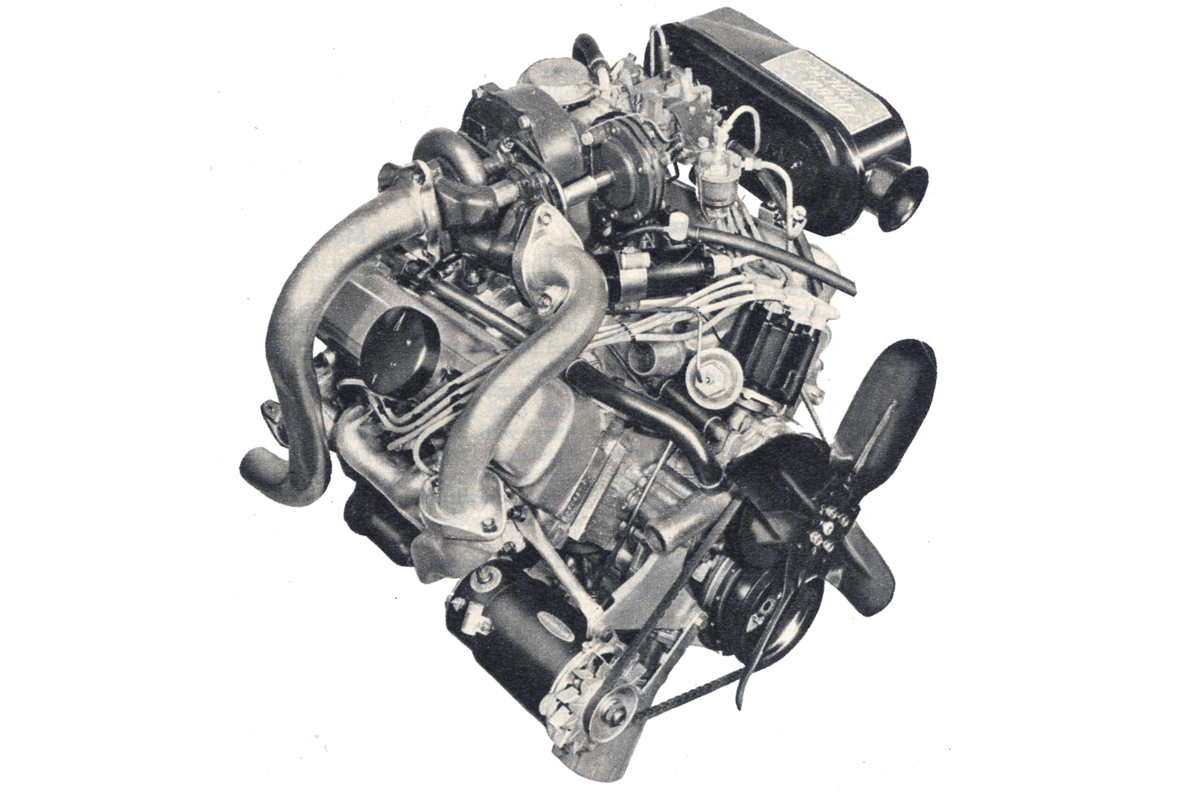

Turbos appeared on a pair of General Motors (GM) models: first the Chevrolet Corvair Monza and, just weeks after, the Oldsmobile Jetfire. These were not the first forced-induction cars, however; cars including the Graham eight-cylinder (1934), Cord 812 (1937) and Studebaker Golden Hawk (1957) had already employed superchargers.

Turbos appeared on a pair of General Motors (GM) models: first the Chevrolet Corvair Monza and, just weeks after, the Oldsmobile Jetfire. These were not the first forced-induction cars, however; cars including the Graham eight-cylinder (1934), Cord 812 (1937) and Studebaker Golden Hawk (1957) had already employed superchargers.

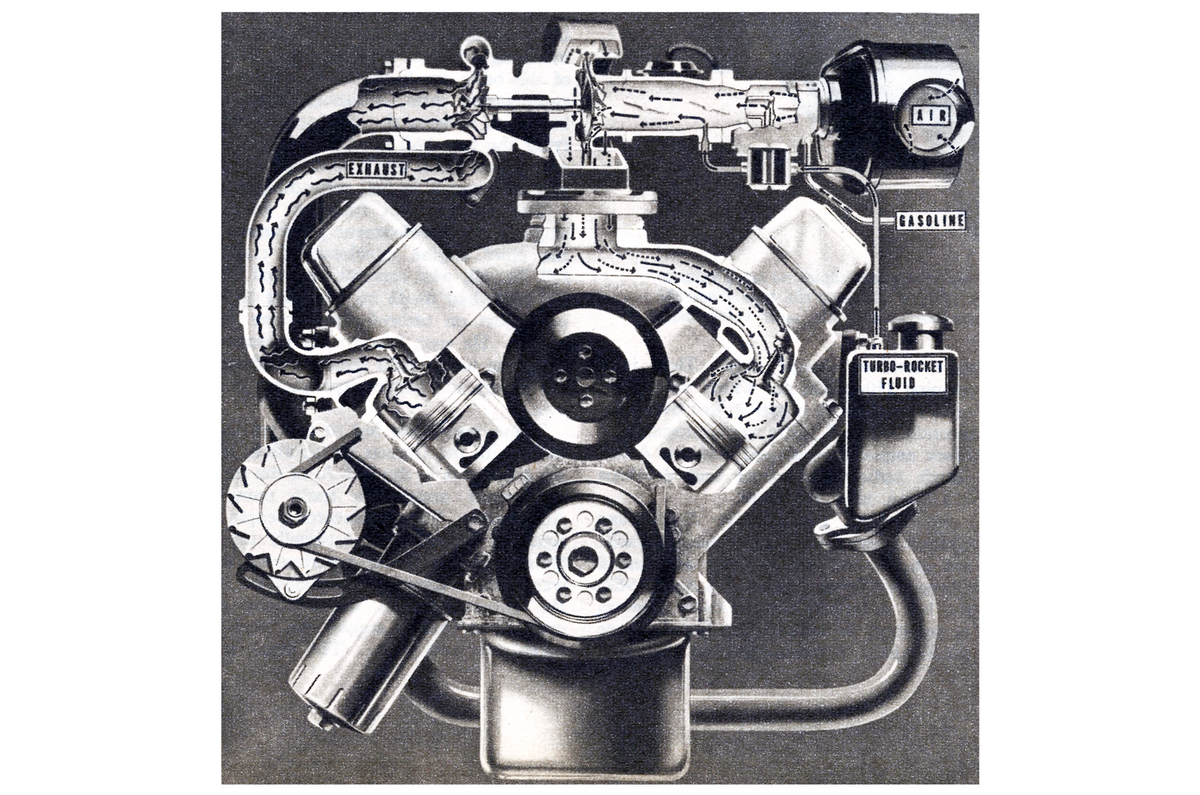

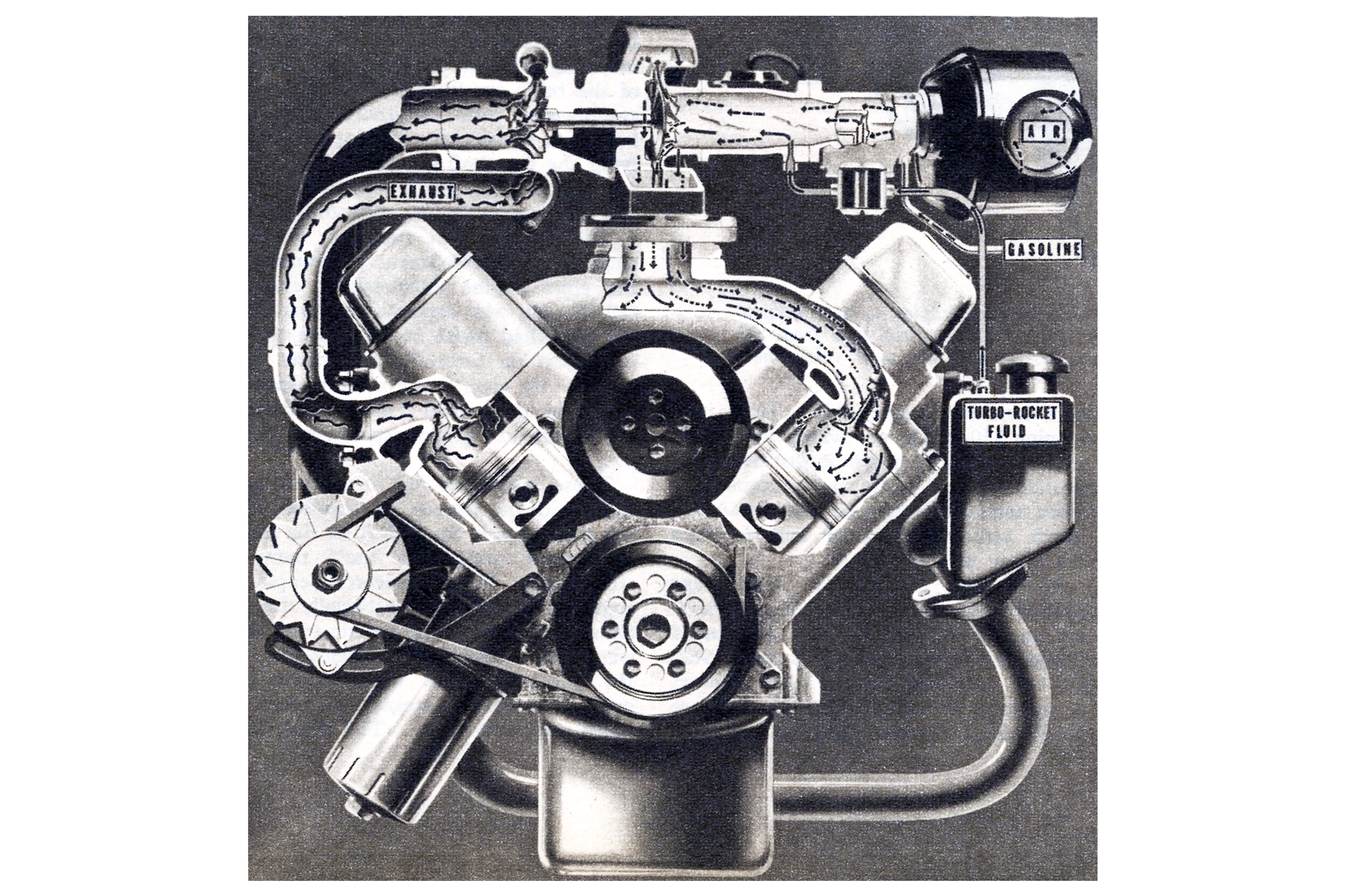

On 27 April 1967, Autocar's JP Norbye explained how the Jetfire's newfangled device worked.

"By adding the turbocharger to the [3.5-litre, aluminium-block] V8 engine, the Oldsmobile engineers have won a 40% power increase in the mid-speed range," he wrote. Indeed, the turbocharged engine made 215bhp, affording a 0-60mph time of less than 9.0sec. And, amazingly, this was done "without affecting engine flexibility, durability or fuel economy".

"These results could not have been obtained by increasing the cubic capacity of the engine or installing a larger, existing unit. Tuning of the basic V8 by raising the compression ratio, installing larger carburettors, revising the porting and modifying the camshaft would lead to a top-end power gain, but a loss of flexibility and an increase in fuel consumption".

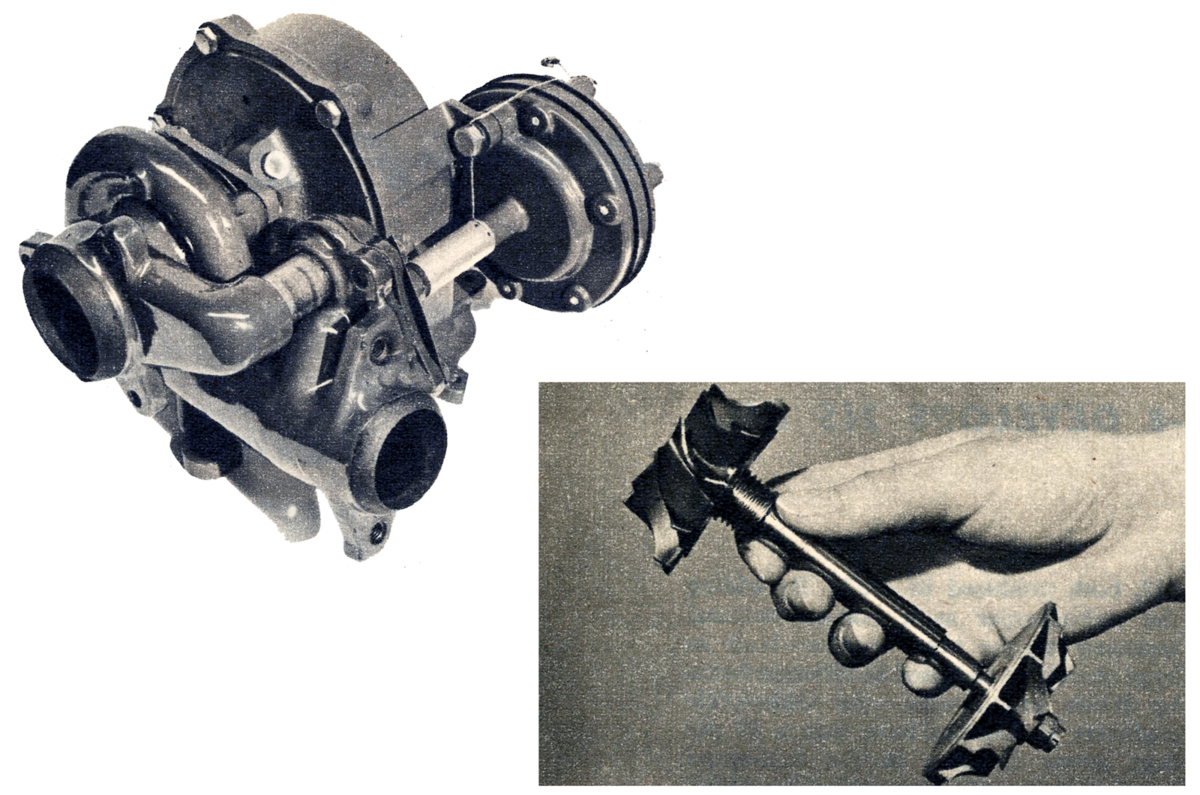

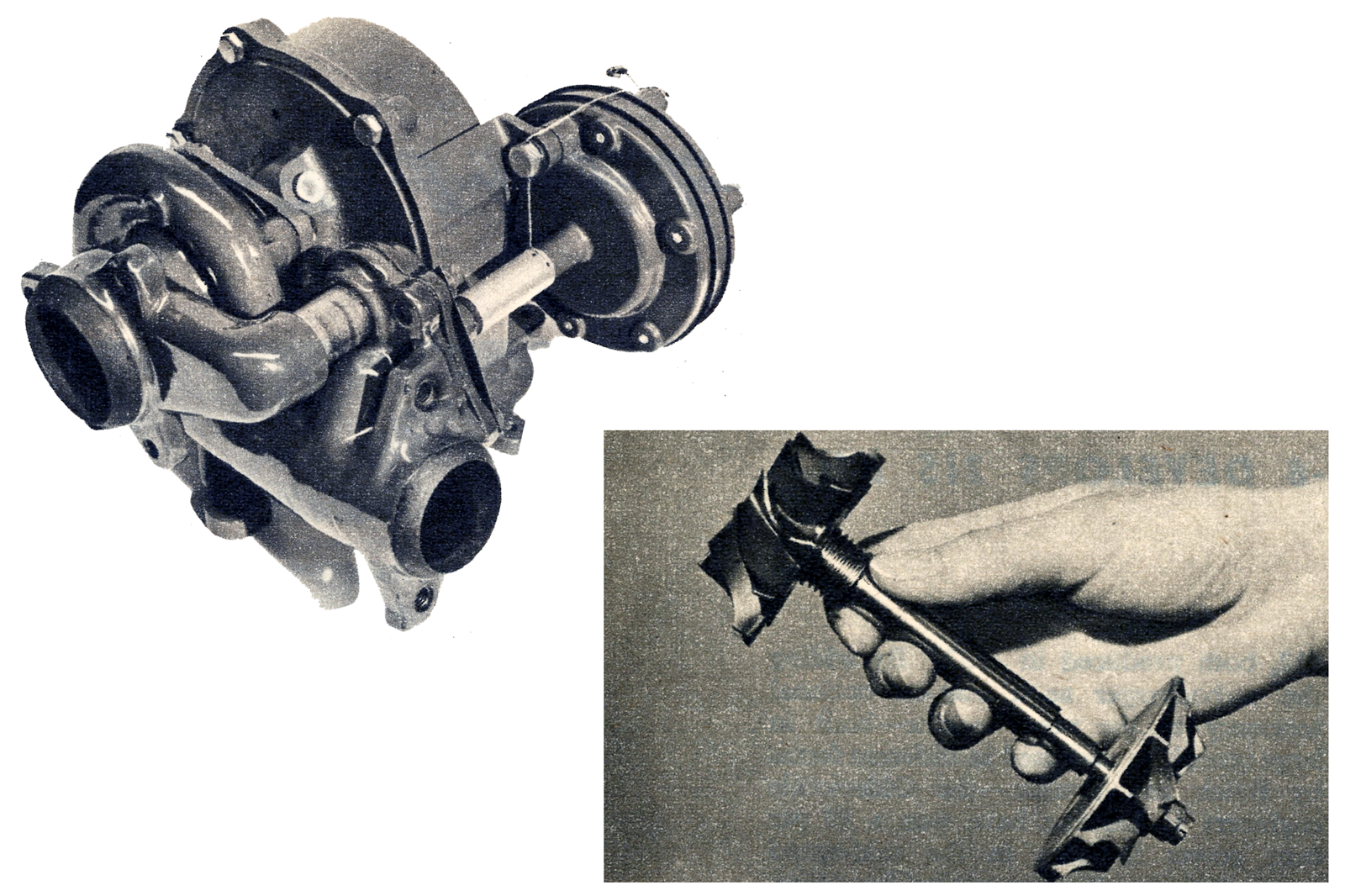

The turbocharger was supplied by Garrett AiResearch, an innovative aerospace company whose products included intercoolers, turbines, cabin pressurisation systems and early flight computers, and whose later feats included involvement with the first turbo car to win the Indy 500, first turbo car to win Le Mans and first production turbodiesel car (the US-market-only Mercedes-Benz 300SD of 1978).

The turbocharger was supplied by Garrett AiResearch, an innovative aerospace company whose products included intercoolers, turbines, cabin pressurisation systems and early flight computers, and whose later feats included involvement with the first turbo car to win the Indy 500, first turbo car to win Le Mans and first production turbodiesel car (the US-market-only Mercedes-Benz 300SD of 1978).

"But a little thought will make it clear that blower pressure has to be limited. The high volumetric compression ration of 10.25:1 also makes it necessary to inject a water-alcohol mixture, and the carburettor is coupled to a metering device, with connections to a bypass should the fluid reservoir run dry."

"But a little thought will make it clear that blower pressure has to be limited. The high volumetric compression ration of 10.25:1 also makes it necessary to inject a water-alcohol mixture, and the carburettor is coupled to a metering device, with connections to a bypass should the fluid reservoir run dry."

Our report said: "Maximum efficiency is designed to come in between 2000 and 2200rpm, but boost remains high up to 5000rpm. Maximum power is developed at 4600rpm, as against 4800rpm for unblown versions of the V8.

Our report said: "Maximum efficiency is designed to come in between 2000 and 2200rpm, but boost remains high up to 5000rpm. Maximum power is developed at 4600rpm, as against 4800rpm for unblown versions of the V8.

Join the debate

Add your comment

Rover V8

Rather a pity that BL didn't snap up this technology when they bought the rights to the nearly identical Buick V8 makes you think what the Rover engineers could have done with it.

Autocar wrote:

How big's a gallon, US or imperial?

I pity the Ferrari 488 Pista and it's tractor-like 8,000 rpm redline

Nor the Blower Bentleys.

... not to forget the series

... not to forget the series of pre-war supercharged Mercedes from 1921, culmulating in the gorgeous 540K