The motoring industry is never finished with new-found technical achievements and advancements, and never has that been clearer than in 2023.

This year, our technology correspondent Jesse Crosse covered just about every facet of automotive advancement, from a UK firm developing a 12,000rpm Porsche engine to tyres made out of old plastic bottles.

Here, we count down our favourite innovations from the past year. If you would like to find out more, you'll find a link underneath each one.

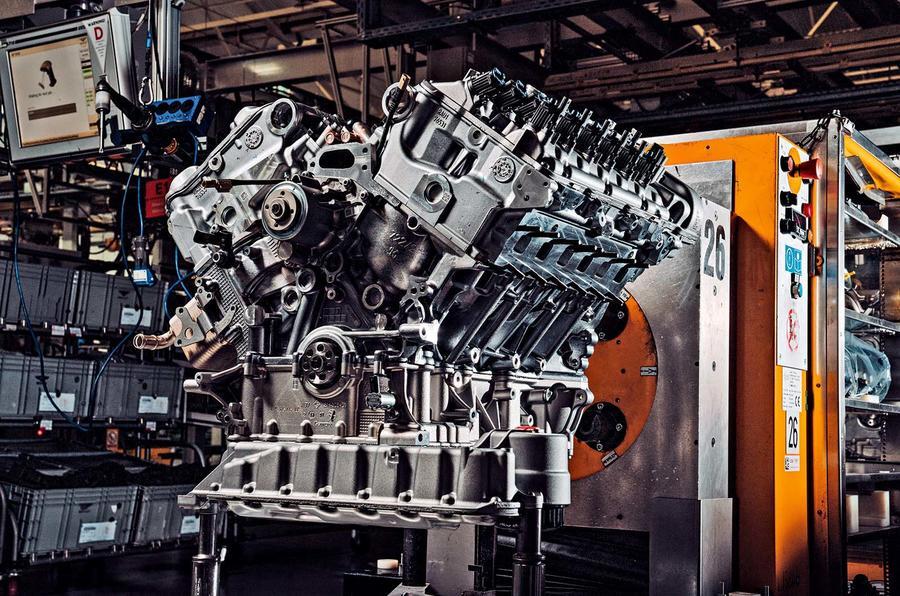

A Porsche 911 engine that hits 12,000rpm

An upgrade for a Porsche engine might not sound that exciting, but this new four-valve cylinder head from Swindon Powertrain promises to turn it into an absolute screamer.

The kit is designed to be compatible with Porsche's M64 engine, which powered the 993- and 964-generation 911s, and uses two inlet and two exhaust valves rather than one of each.

This allows more air into the engine at higher revs without compromising the speed of the air entering.

What that means for the driver is a good torque spread, more power and, crucially, the ability to rev higher. With some internal fettling, 12,000rpm is achievable - nearly twice that of the standard 993's 6900rpm redline.

How to make a 12,000rpm Porsche engine

Interior lights that imitate sunshine

It was billed as "near-sunlight" lighting. Volvo drew the industry's attention to the potential for new-design LEDs to create a level and colour of interior light that enters the territory of mood enhancement.

The brief for Volvo's design team was to bring artificial sunshine to an EX90 owner's gloomy morning, using a range of colour temperatures that are said to be on the same colour spectrum as sunlight.

What does this mean for the passenger? Apart from bathing the interior in a warm glow, it's supposed to boost serotonin levels. It works in buildings, so why not cars?

Volvo's new interior lights that imitate sunshine

Fuel made out of fresh air

The wonders of direct air capture technology amazed us back in September.

This captures CO2 from the atmosphere and combines it with green hydrogen (made during electrolysis powered by wind-generated energy), and the product of this fusion is an e-fuel that's chemically equivalent to fossil petrol.

Therefore it can be used in existing combustion engines and even as jet fuel. If it were to be scaled up, it could be distributed around the world's filling stations.

The process by which the fuel is made is also quite simple, using a combination of CO2 filters, wind turbines and an electrolyser.

How to make fuel out of fresh air

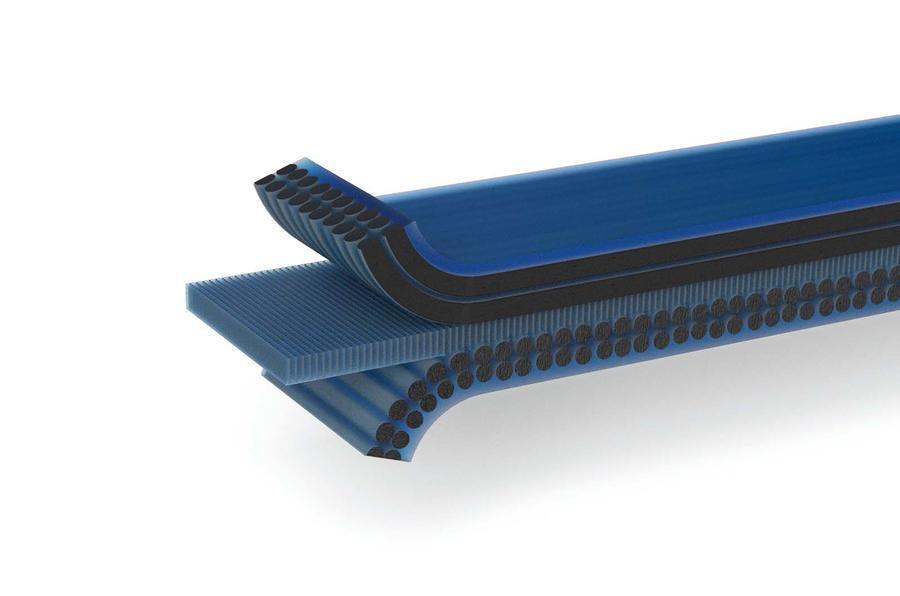

Sustainable tyres in production

Soybean oil, rice husks and plastic bottles: these aren't materials that you would expect a tyre to be made from, but Goodyear has found a way to make it work.

Add your comment