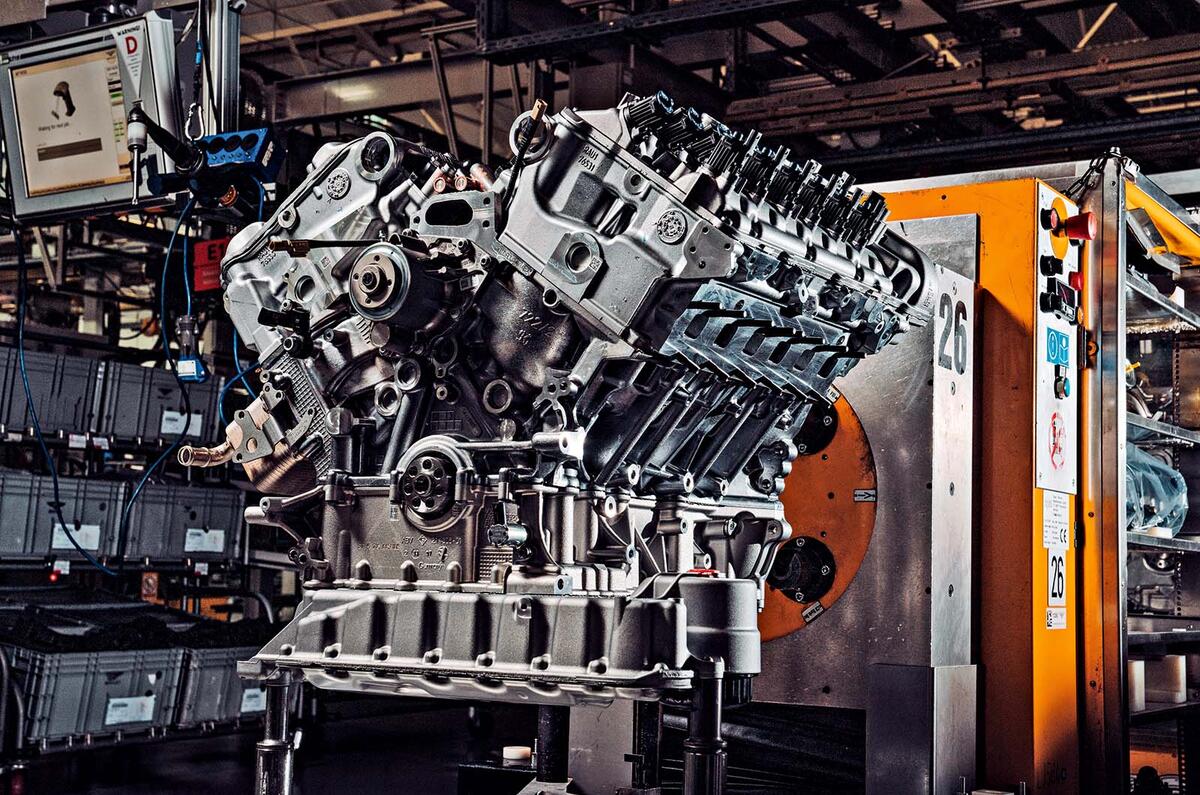

The news that Bentley is discontinuing production of the unique W12 engine is inevitable. Bentleys will be fully electrified from the start of the next decade and, like it or not, the days of 6.0 -litre 12-cylinder petrol engines have been numbered for some time.

The W12 is something of a masterpiece, though. For such a niche machine launched more than two decades ago in the Volkswagen W12 concept car, a final production figure of 105,000 units for the Bentley version in production for exactly two decades isn’t bad going.

The W12’s name is a bit of a stretch in that it implies four banks of three cylinders, rather than two banks of six. In fact, its design draws on the Volkswagen VR6 engine launched in 1991, which is equally if not more ingenious in its configuration.

An engine’s cylinders are almost always arranged in a straight line, which is fine unless space in the engine bay is at a premium. That’s the case in transverse applications, which is why most six-cylinder front-wheel-drive cars are fit ted with vee-configuration engines.

V6 engines normally have two cylinder banks with three cylinders in each. The most common angle between the cylinder banks is 60deg and there are two cylinder heads, up to four camshafts and two exhaust manifolds. The inlets would normally be in t he centre of the vee sharing a common throttle body.

As with any thing, the typical V6 is a trade-off. The engine is a lot shorter than an in line six, which benefits longitudinal configurations as well as transverse, but it’s wider. It also lacks the natural perfect balance of a straight six and packaging the exhaust is more complex than for any inline engine.

The Volkswagen VR6 is a cross between a straight six and a V6, gaining some of the size advantages of the straight six with none of the downsides.

It has one cylinder block but instead of the cylinders being arranged on one centre line, they sit alternately on two parallel centre lines in a staggered fashion, allowing them to be slightly overlapped.

As a result, the engine is shorter than a straight six and narrower than a V6. It also has one cylinder head and one exhaust manifold instead of two, and it retains the firing order of a conventional straight six at full chat.

With that in mind, it’s easy to picture what the W12 looks like with one ‘proper’ vee and a pair of sort-of-vees, and it’s wonderfully compact into the bargain. Each bank has its six cylinders arranged in a 15deg staggered formation and then the two banks are inclined at 72deg.

The cunning VR6 legacy makes the engine 24% shorter than it would have been had there been conventional cylinder arrays.

Destined for the Batur, the W12’s swansong will be a mere 18-off, uprated examples producing 739bhp and 737lb ft thanks mainly to reworked induction systems, a new turbocharger compressor design, larger intercoolers rejecting 35% more heat from the compressed intake air, and revised engine calibration.

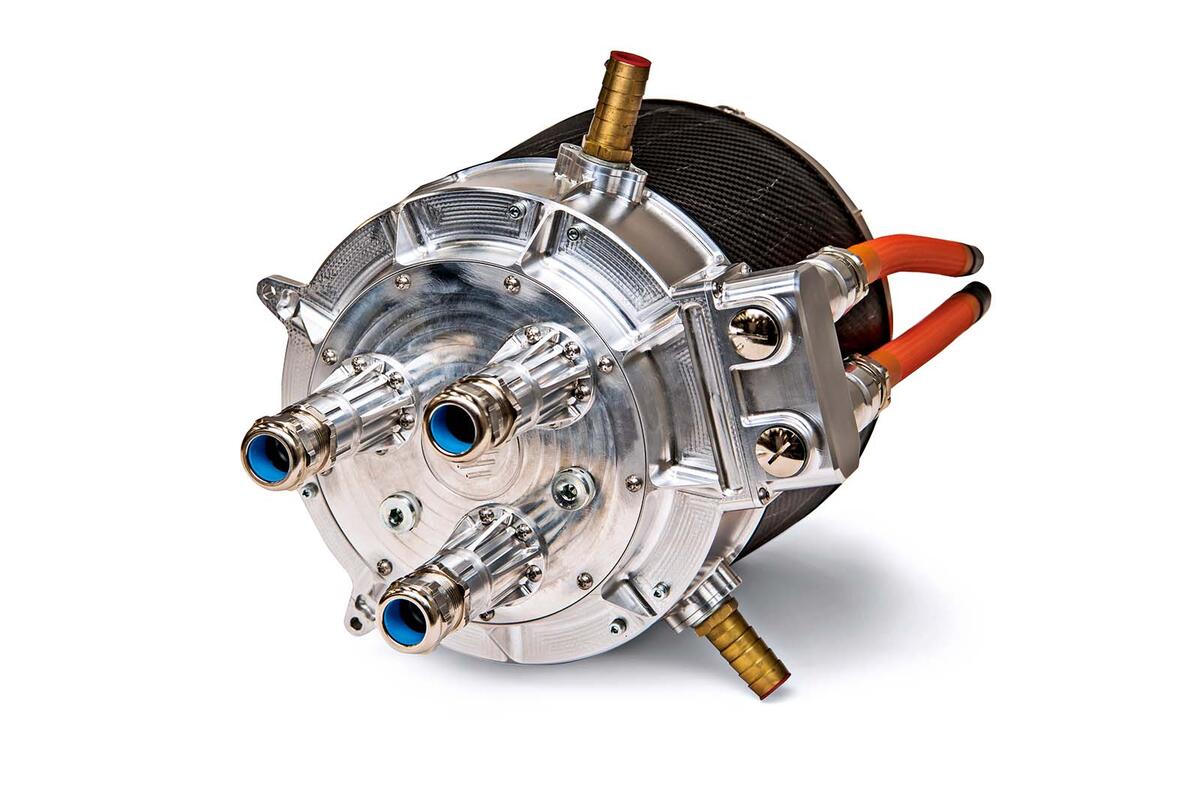

The electric motor developed with rocket science

It’s literally rocket science. This tiny, super-advanced electric motor was designed as a fuel pump for Australian firm Gilmour Space Technologies’ Eris rocket programme by UK firm Equipmake, better known for its vehicle electric drive motors and inverters. The HPM-400 can produce a staggering 536bhp and 184lb ft, yet the entire system, including silicon-carbide inverter, weighs just 40kg. It bodes well for the future of EV drive systems.

Add your comment