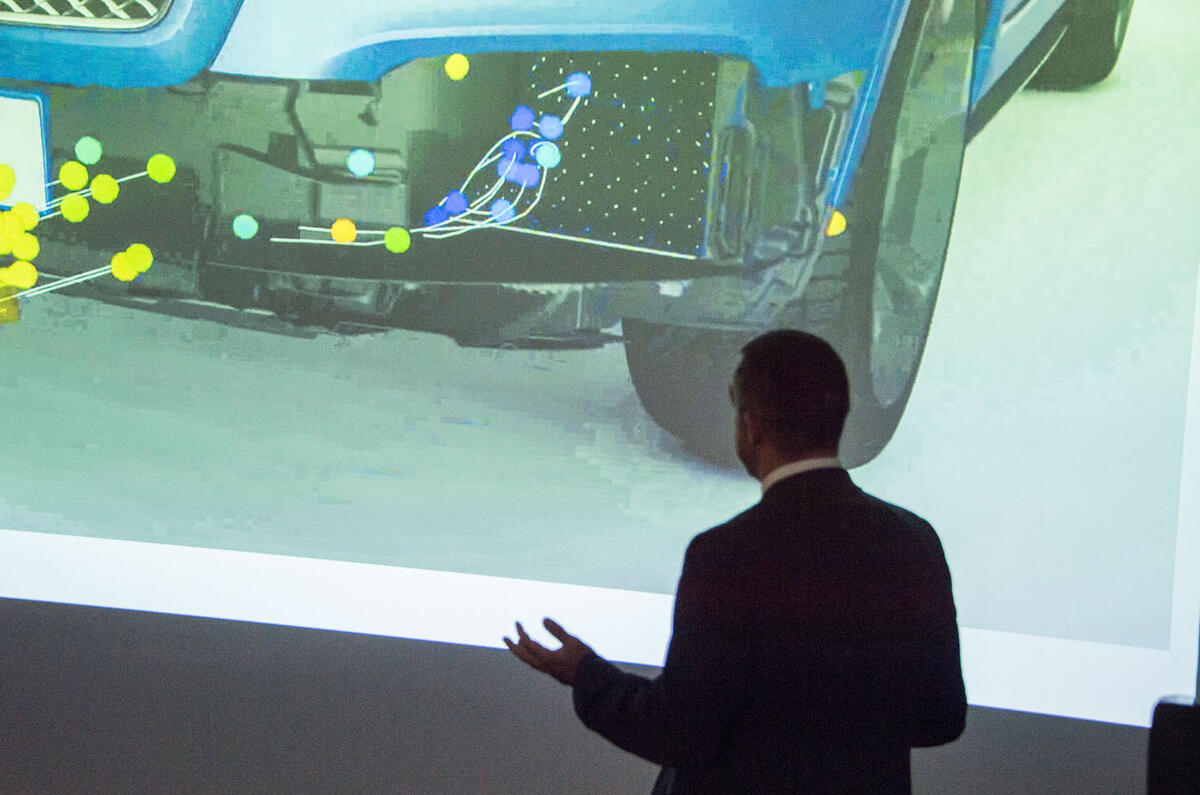

In a Bentley Bentayga, there are more than 90 electronic control units secreted within, besides the powertrain, the air suspension and its anti-roll systems and a cooling pack that can cope with a W12 and four fat wheels threshing through sand in 40deg C temperatures.

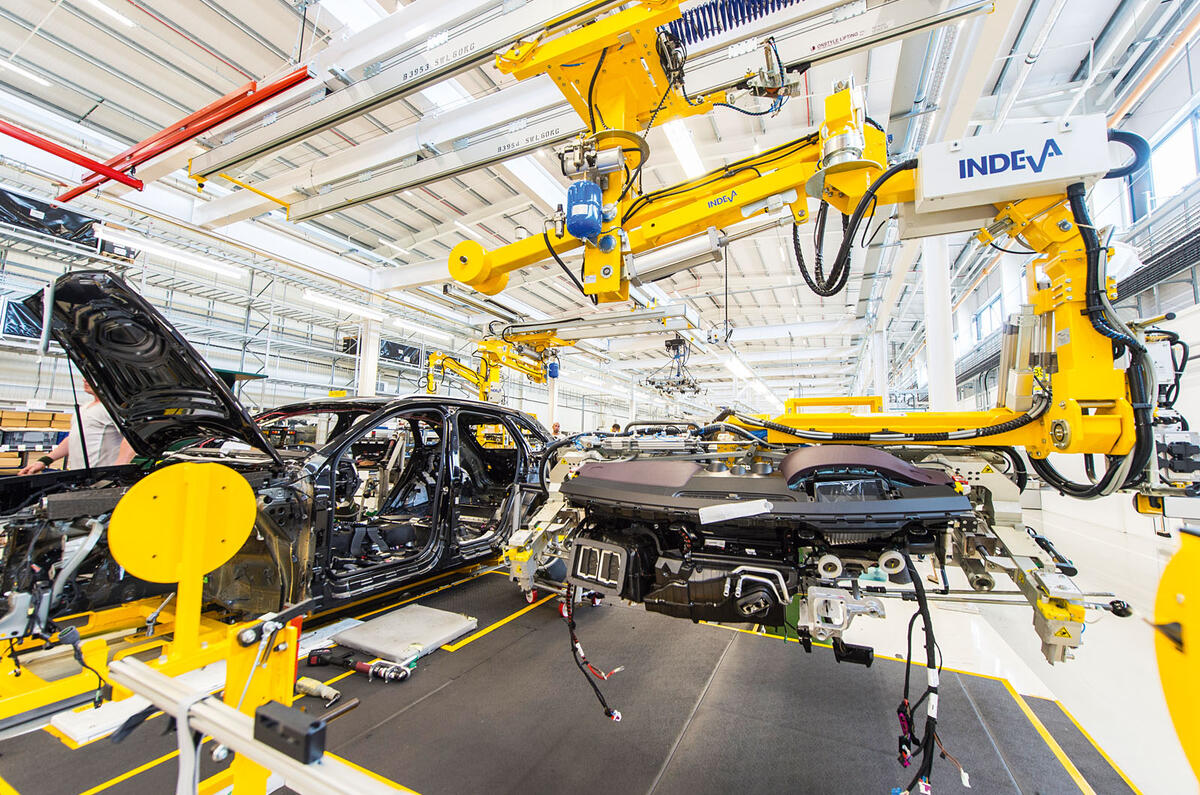

Clips, conduits and clamps, ducts, sound dampers and seals – these are just some of the myriad parts that locate, cement, energise and cool the clusters of components that make up the unseen innards of your car.

In a designer’s world, these components are the car’s ‘B-side’, the flipside of the panels that clothe it to provide a visual character. Designing the A-side is challenging enough. A car’s shape does much to determine its likely success, which is why the design process is invested with so much time, effort, agonising and inspiration.

The B-side is all about realising the car’s function and the engineering of everything from a draught excluder to a differential. There are aerodynamics, crash performance and passenger packaging to consider, besides the reams of rules around light location, bumper heights, internal projections and pretty much every other aspect of a car’s essence.

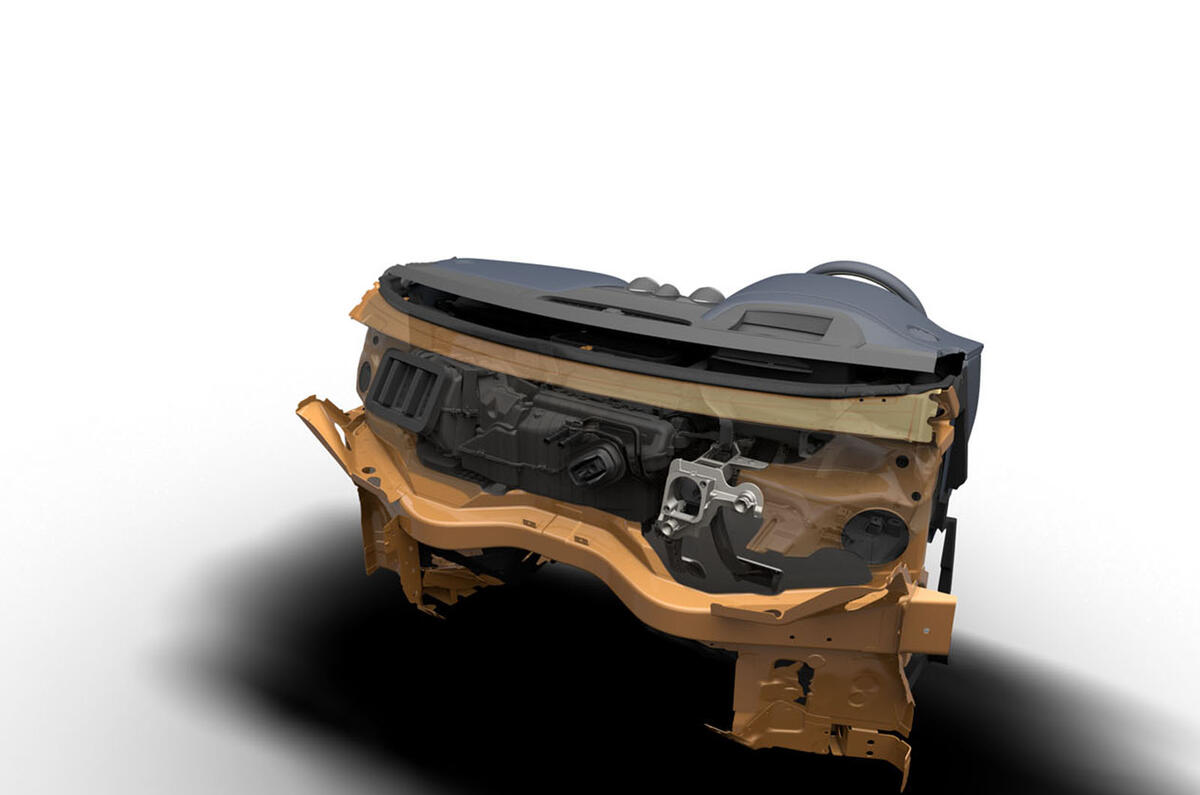

At least as difficult is to plan the three-dimensional world beneath the car’s skin. The Bentayga may be big, but you only have to glance at the cutaway below to see that every nook, cranny, crevice and orifice that isn’t given over to occupants and their belongings is ram-packed with stuff. Fitting them all in so they live a reliable, interference-free life within an envelope largely dictated by the design department is a massive challenge. How it’s done is what we’re here to discover.

Read our Bentley Continental GT review

Join the debate

Add your comment

Lots of negativity (jealousy?

Compared with the Tesla Model S cutaway

It is immediately apparent that the Bentley is a bit of an ugly dinosaur.

Compared with the Tesla Model S cutaway

It is immediately apparent that the Bentley is a bit of an ugly dinosaur.