Right about now, the sleek Bloodhound land speed record car will be docking in the UK after last autumn’s high-speed test programme on a dry lake bed in the South African desert, where it hit 628mph in the hands of its driver, Andy Green.

I say ‘high speed’ but, for Bloodhound LSR, it’s running on only two-thirds power. The test was a prelude for a return to the remote Hakskeen Pan, in north-west South Africa close to the Namibian border, in 12 to 18 months, where the car will make an attempt on the land speed record that Green has held since 1997, when he took the twin-jet Thrust SSC to a supersonic 763mph.

Bloodhound LSR’s target will be over 800mph and a new land speed record. That might be the first thing you note about Bloodhound LSR: the target was once 1000mph, which is now ‘phase two’ if, after reaching a new record, there’s sufficient commercial and public interest in taking it to four figures.

Which brings me to the second thing you might note about Bloodhound LSR, in that instead of its old blue and orange, it’s now white, in a ‘your company name here’ kind of way, the project having been rescued from administration by Ian Warhurst, former owner of turbocharger company Melett, eight days into a retirement he abandoned late in 2018.

Since then, things have moved – if you’ll pardon the expression – quickly. The autumn test programme was only put into place last July. Here, in the words of Bloodhound LSR’s chief engineer, Mark Chapman, and Green, a former fighter pilot and the team’s mathematician, is what Bloodhound is, how you run it and how you drive it.

What is it?

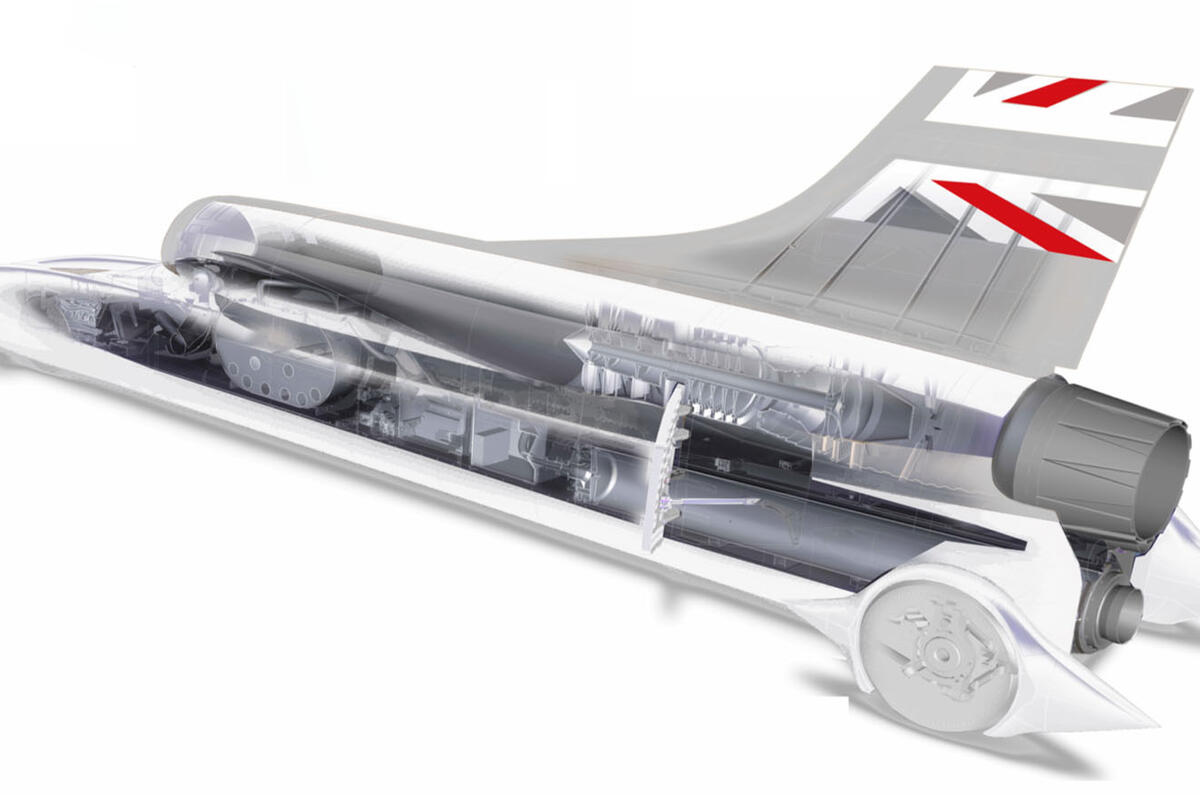

At 13.5m long, Bloodhound is about three times the length of a normal family car. “The front third is an all-carbonfibre monocoque,” says Chapman, “which houses the driver safety cell and also the high-test peroxide tank,” fuel for the rocket that will be supplied by Norwegian company Nammo. To date, Bloodhound has been run with a Rolls-Royce Eurojet EJ200 engine borrowed (literally; the owners will want it back) from a Eurofighter Typhoon fighter jet. That provides around 20,000lbf of thrust. The monopropellant rocket is expected to add up to another 9000lbf.

Behind the front section is a “steel and aluminium lower chassis that holds the fuel tanks, and on top of that we’ve got a titanium and aluminium chassis, which houses the jet engine and also mounts the fin”.

Thrust SSC used two engines, side by side, which negated roll (which we’ll come to later). “The reason Bloodhound is as narrow is to reduce the frontal area,” says Chapman, “to drive that drag down to as low a number as possible.” Overall width is about 2.5m, but “as front track goes, it’s still pretty narrow. It’s not a very wide car.”

The bodywork is mostly stressed, and since the car’s 2009 inception under Richard Noble, there have been a few key changes: “The jet and the rocket have switched over, and the fin has got a lot bigger.”

At conception, the jet was mounted beneath the rocket because it’s heavier, but when the rocket’s thrust kicked in, it would have pushed Bloodhound nose-down. There were adjustable winglets at the front to counteract that but “we couldn’t find a way of making that system fail-safe,” says Chapman, “so if you swap the jet and the rocket over, because the rocket is a lot narrower, you can mount it a lot lower to the ground, so how they are now, they pretty much straddle the centre of gravity”.

Because the huge aluminium wheels aren’t engine driven, Bloodhound doesn’t need downforce to create grip. In fact, lift neutrality and minimal drag is optimum. “The anomaly is that you generate an increasing amount of downforce until about Mach 0.6, or about 400mph or 500mph,” says Chapman. “Then from Mach 0.6 upwards, downforce starts to reduce, and when you get to about Mach 1, there’s no downforce, and supersonic it starts to generate lift at the back, so you need rear winglets.

“The surprising bit about testing was how close the aerodynamic modelling was. Bear in mind you’ve got maybe three different ways of modelling the aerodynamics computationally. On one or two of the simulations, it matched the line completely. We were expecting up to 20% scatter on the data from prediction to reality. On most of the run, we were within 5%. If you saw that on a PhD paper, you’d expect they’d cheated, so the aerodynamic model is almost unbelievably good.”

Chapman talks numbers – huge numbers – as casually as if you were talking to me about speeds on the way to the shops. “All our drama was below 350mph if you like,” Chapman says, “getting a car running reliably – silly things like power leads, sensors not quite working, debugging it.” After deciding in July to head to South Africa for jet-only testing, “literally, we gave it a lick of white paint, packed the car, flew it out there with no testing since 2017 at Newquay airport – it was pretty much mothballed after that. And in the first couple of weeks in South Africa, we were very much debugging it, getting the engine started, finding a sensor wasn’t working and, until 350-400mph, there seemed to be this snag list of stuff to solve.”

That phase cleared, though, and things improved remarkably. “Once it was running, over the last three runs, it was just huge 80mph steps each run,” says Chapman. “I wouldn’t say it was effortless, but there was no surprise it worked as well as it did.”

How do you run it?

There’s a reason Chapman says it isn’t effortless: running a 600mph car in very hostile conditions in the middle of nowhere is as hard as it sounds.

“We’re running coming into the late spring/early summer in the Kalahari desert and, oddly enough, it’s quite warm,” Chapman says with understatement. “We knew it was going to be in the high 30s. I think it got up to about 43deg. That’s quite a challenging working environment. Glibly, before, we’d said: ‘It’ll be fine. We’ll have a cold drink.’ But actually just operating in those temperatures is quite difficult. We run a turbine to get the EJ200 engine going, and it’s quite elderly, and that was struggling at an altitude of nearly 1000m, so it’s got less puff. So we’d be out there by 5am, ready to run by 5.30am, and the coolest we ran was at 17deg, so even dawn is quite warm.”

After 16-hour days, the team stay in a hunting lodge around 40 miles from the car’s base, which is, crudely speaking, a big tent on the edge of a dried lake bed, 600 miles from Johannesburg and 160 miles from the nearest supermarket.

“We’d prep the car the night before,” says Chapman, “have it fully fuelled, check all the computer systems, have it ready at the front door with the towing strap attached.”

First thing in the morning, the team would perform “a run brief while we’re booting up the systems” and perform final checks. “Then we tow the car out to the desert. It takes about half an hour to get it to position. Then you do the actual prestart checks. Andy will do his walk around with his start team and, like an aircraft, they’ll check the intakes, that everything’s securely attached to the car, and then Andy will get into the car and go through his pre-flight checks, boot up the computers.

“We’ll have an umbilical plugged into the car, too, checking that, as the computers come online, we’re getting the right data. Andy gets his helmet on and the hatch locked down, and we go through the start system. We start our air-start kart. Then, when that’s up to temperature and pressure, that opens a valve into the EJ200 gearbox and starts to wind that up.”

“One of the beauties of the engine is that it’s a very clever engine,” says Chapman. “Sometimes, that can be its handicap, but it’s got its own health monitoring system, so before a run, we check its ECU in effect. Its diagnostics are very good.” That said, although it is “a very modern jet engine”, it is not new. “This engine last flew in an aircraft in 1997,” says Chapman. “Yes, it’s an engine from a Typhoon but it’s the test aircraft, from before this millennium. So there is a certain amount of hilarity when you’re on a programme to talk about future technology and, in the background, we’ve got a computer running Windows 95.”

All going well, the EJ200 starts and the car is, then, ready. All going well. “One thing we found with the higher temperature is that it takes longer to start, and on the EJ200, there’s a one-minute timer, so if it hasn’t started in 60 seconds, automatically it aborts,” Chapman explains. “There’s the hot air temperature, you’re at altitude… it just takes more puff to get it going.”

But once it is going? Green – the world’s fastest man – takes up the story.

How to drive it

If you found yourself in Bloodhound’s cockpit, the major controls would be familiar major controls. There’s a steering wheel and “right foot for the loud pedal and left foot for the brakes”, says Green.

Then mostly there are digital displays. “Thrust SSC was very much an analogue-era car,” says Green, “so it had a series of round dials that would show one thing only.” By comparison, “Bloodhound has got three fully programmable high-definition LCD screens so it’s got a full-colour cockpit and, on a couple of occasions, we’re introducing things,” such as the team adding a gearbox temperature display to the monitor while they were out in South Africa.

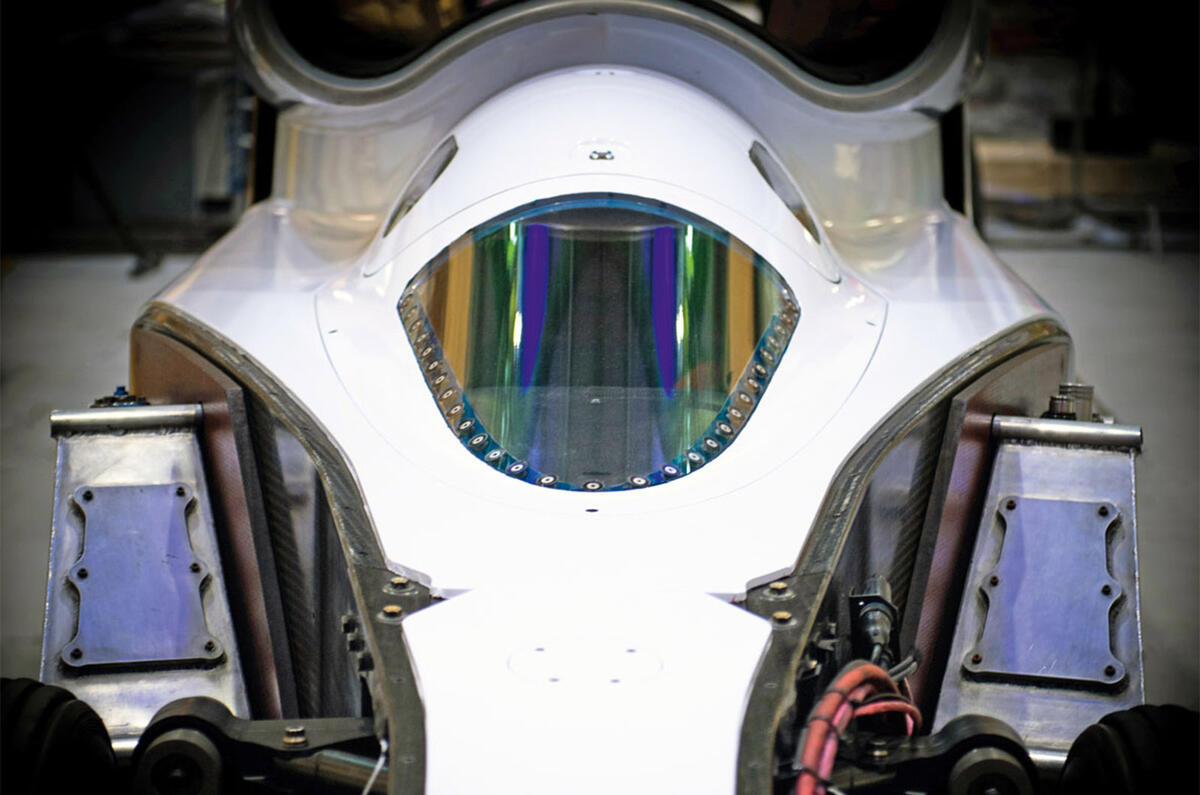

Once ensconced, “I can see the track directly ahead of me plus or minus 10deg or 15deg,” Green says. “It’s a relatively narrow amount but, most of the time, the car’s going in a straight line.” That said, while in an ideal situation you would line up Bloodhound pointing where it wants to go and then start it, likely as not the team would start it into the wind to give it every chance to fire.

From there, Green has to drive it to the start line. Lining it up from its idling position to the start might be a 250m turn, which “sounds absolutely vast, but if you’re on a 16km track, a quarter of a kilometre is nothing”.

The car’s steering ratio – the amount you turn the wheel versus the amount the wheels turn – is 40:1, versus a typical family car’s 15:1 or so.

“The steering wheel rotates through 200deg, and that’s more than enough for a car that’s travelling at several hundred miles an hour,” says Green. The front wheels turn by 5deg each way “just to make it manoeuvrable enough to turn it under its own power, which saves you a whole bunch of time hooking it up to a 4x4”, a process that would also make the windscreen dustier.

The throttle is “fully variable like a car throttle, but when you say progressive, it’s a progressive amount of 54,000 thrust horsepower,” Green explains. “A small amount of that is still a lot. It’s also non-linear. We’re using one of the maps from Eurofighter Typhoon, which has two. It’s got a ground map where the first part of the throttle gives you very little change because that’s how pilots taxi. Then the second part of the throttle gives you much more per millimetre during take-off because you’re not refining the throttle to stay in close formation or anything. It has a different map for flying which is much more linear. We’re using the non-linear map for the same sorts of reasons.” Above about 100mph, Green uses the jet’s afterburner, where “I don’t need such a progressive throttle, because I’m not featuring it much under those conditions”.

‘Those conditions’ included runs up to 1000km/h last November. While the surface doesn’t give the car too many issues, other things do, mostly related to crosswinds.

Bloodhound is a “relatively tall car,” Green says, owing to its narrow two-engined design, “so it’s got quite a high centre of gravity, and what that means is that your static roll (ie from a gust of wind) makes the car lean over, and your dynamic roll (putting a steering input in) also makes the bodywork lean just like it does in a normal car. Both of those are higher than a normal land speed record car.” Thrust SSC had two engines side by side not because it needed that much power, but because its 3.5m-wide track meant roll just wasn’t a factor.

“Roll is something you never want to feel in a land speed record car,” says Green. “So the first couple of times in gusty crosswinds and feeling the car roll, I was thinking: ‘This just doesn’t feel right.’ But, of course, that’s against the model of the perfect LSR car that never rolls.

“So in the first couple of runs, it was a case of just getting used to it. What does it feel like under controlled conditions and what’s the correct amount of steering to put in within those bounds? Does that affect my control authority?’ Once I got used to that, it just felt like part of the car, but initially, it was an odd feeling. I told the team a couple of times that for a land speed record car, it felt like it handled like a bit of a pig in crosswinds, because of that unsettling – tiny, tiny, only a few degrees – of roll, but it’s so unusual to feel in a car like that. If you were in a normal saloon car, you wouldn’t even remark on it; less normal in a race car; in an LSR car, unusual to the point of uncomfortable.”

If you see video footage of a run – and I suggest you do – you’ll see Green looks quite busy at the wheel. “The faster you go, the less mechanical grip you get from the wheels,” he says, “so you have to put quite a lot of steering in to actually keep the car going in a straight line.”

‘Quite a lot’ is about three of its five degrees of steering lock, a full armful of turn in Bloodhound, which in a family car would equate to about 45deg on the steering wheel. “That doesn’t sound very much,” says Green, “but have a think about applying 45deg at motorway speeds and it starts to sound like a scary amount. Then think about doing it at five, eight, 10 times motorway speeds and it’s a ludicrous amount of steering, but that’s the sort of steering it takes to keep a straight-line racing car, at very high speed, going in a straight line.”

That said, Green says he’s “not terribly worried about what the dynamics will feel like in the car we’ve been driving, because we’ll never drive that car again. As soon as you put the rocket in [it changes] and we’re going to make various other modifications which will affect the mass and centre of gravity. So as soon as we put the rocket in, the centre of gravity will move back, crosswinds and gust sensitivity will reduce because we’re narrowing what we call the static margin – the gap between the centre of gravity and the aerodynamic centre in yaw.”

So then, just braking to worry about. Bloodhound runs parachutes that worked “eight out of eight” times with good stability, although that’s still no guarantee they’ll work every time, and on the front wheels there are conventional disc brakes, to use below around 290mph – and no ABS.

Leaving room for margin on all of those meant “the target 500mph-plus was comfortable” during the recent tests. Green says: “600mph-plus was a bit of a stretch target – or 1000km/h for the benefit of an international audience because that would be the icing on the cake.”

“To be able to do that comfortably – the car would have been able to go faster – at that point we’d achieved all the objectives of testing, and at that point there was no point putting more wear and tear on the car,” says Green. “It was brilliantly successful.”

Stay tuned as they aim for more success over the next 18 months.

How does 0-600mph in 40 seconds sound?

That’s how quickly Bloodhound LSR accelerated during its most recent high-speed tests and it will go faster still, with its runs taking less time again but with far higher terminal speeds, when it gets a rocket.

Bloodhound’s engineers think each pass will use something like 300- 350 litres of jet fuel. That’s even less than it used in testing, on account of each run taking less time.

The jet is by those standards “very efficient”, although these things are relative.

Bloodhound’s engineers know that the rocket will use something like 900 litres of high-test peroxide fuel on every single run. So double that for each two-direction record attempt.

Before the afterburner is fired, the Typhoon EJ200 jet engine makes 13,300lbf of force and on reheat 20,239lbf (6kN and 9kN respectively, metric fans). The rocket should add another 50% to that.

The height of the upper chassis stands 2m tall and the tail fin another 2m above that. All told, the car weighs approximately six tonnes.

Bloodhound itself is a large vehicle. It’s 13.5m long, with a 2.2m-wide track at the rear but only 0.9m wide at the front, and a wheelbase of 8.9m.

The previous five land speed record cars

Thrust SSC

Year: 1997; speed: 763.035mph; engines: two Rolls-Royce Spey; location: Black Rock Desert, Nevada, US; Andy Green drove Richard Noble’s Thrust SSC through the sound barrier

Thrust 2

Year: 1983; speed: 633.47mph; engine: Rolls-Royce Avon; location: Black Rock Desert, Nevada, US; Richard Noble broke the record that had stood for 13 years

Blue Flame

Year: 1970; speed: 622.407mph; engine: rocket; location: Bonneville Salt Flats, Utah, US; Gary Gabelich was first to exceed 1000km/h and did so in rocket car

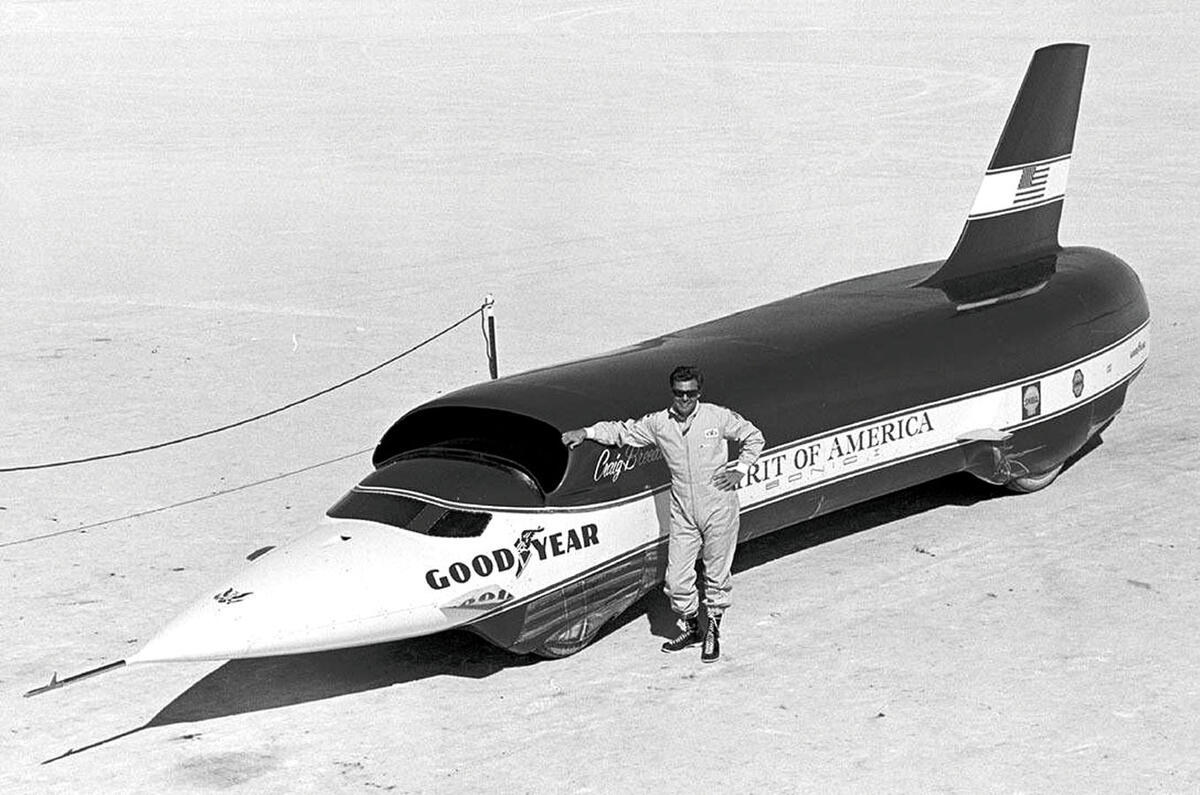

Spirit of America – Sonic 1

Year: 1965; speed: 600.601mph; engine: turbojet; location: Bonneville Salt Flats, Utah, US; Craig Breedlove became a speed record legend in Spirit of America

Green Monster

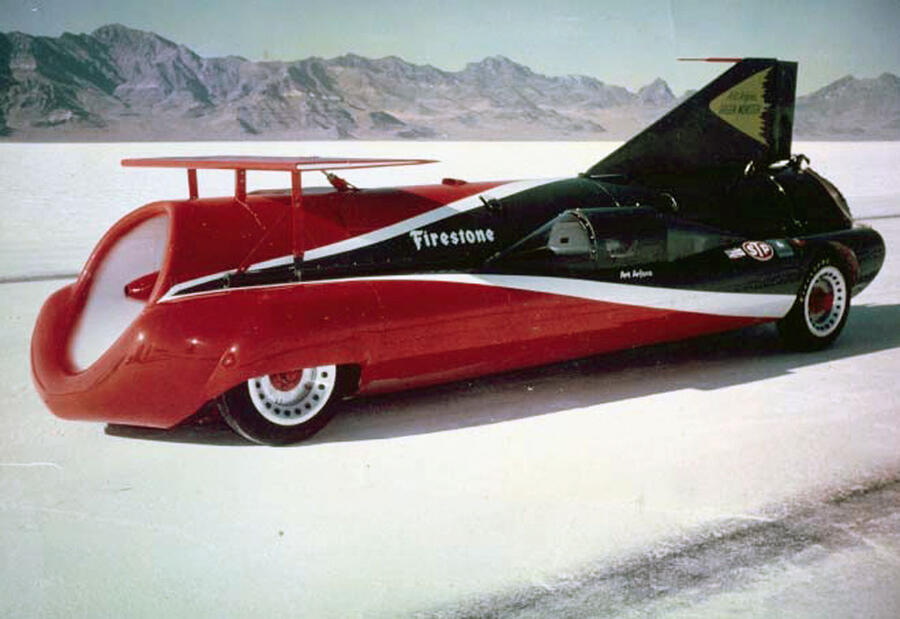

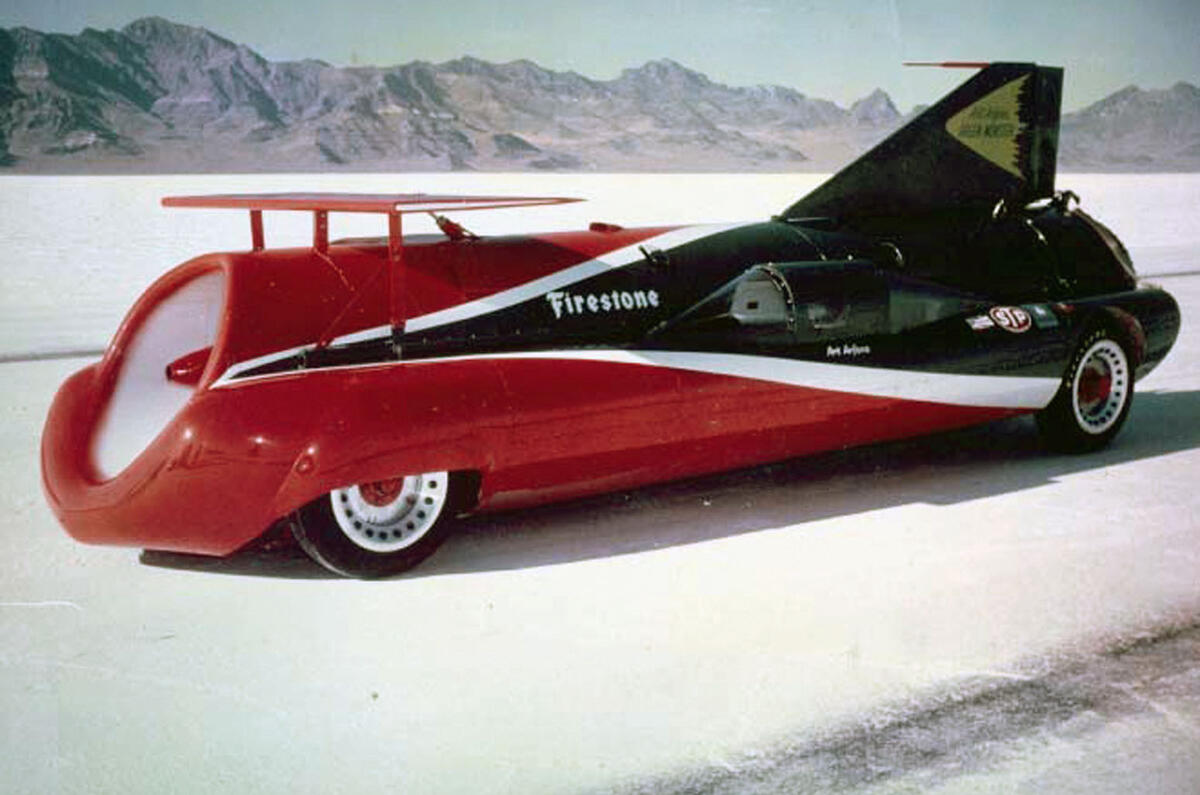

Year: 1965; speed: 576.553mph; engine: turbojet; location: Bonneville Salt Flats, Utah, US; between them, Art Arfons’ Green Monster and Craig Breedlove broke the LSR seven times in 1964 and 1965

READ MORE

Bloodhound LSR reaches 628mph as testing concludes

Racing lines: Bloodhound LSR run fires rockets and hearts

Updated: Bloodhound SSC saved as investor buys 1000mph project

First Bloodhound SSC speed record attempt confirmed for 2019

Join the debate

Add your comment

What a hideous waste of time.

What a hideous waste of time. Now if this were electric.

That would be impressive

Carbon?

I remember watching the original Thrust 2 on Blue Peter as a kid. It was one of the things that inspired me to be an engineer. However are the current young generation going to be inspired by a bunch of blokes burning fossils fuels to go just afew MPH faster? Surely an electric or carbon neutral speed goal would be equally exciting and more relevant.

Bloodhound Rocket Progress???

I wonder what progress is being made with the rocket? Bloodhound have been with Nammo since 2013? Why hasn't it been tested on the car yet? There is not much evidence of progress with the rocket and using it will be a big deal in terms of safety and handling the fuel etc. A lot of people have been supporting this project for many years it's about time they got on with the record, I hope this wasn't just a PR exercise? Lets home genuine progress is being made and the rocket motor and it will be installed soon??