In the second ever issue of Autocar, published 6 November 1895, we published a report from the Cyclist magazine on an electric car that had been built in the summer of 1894.

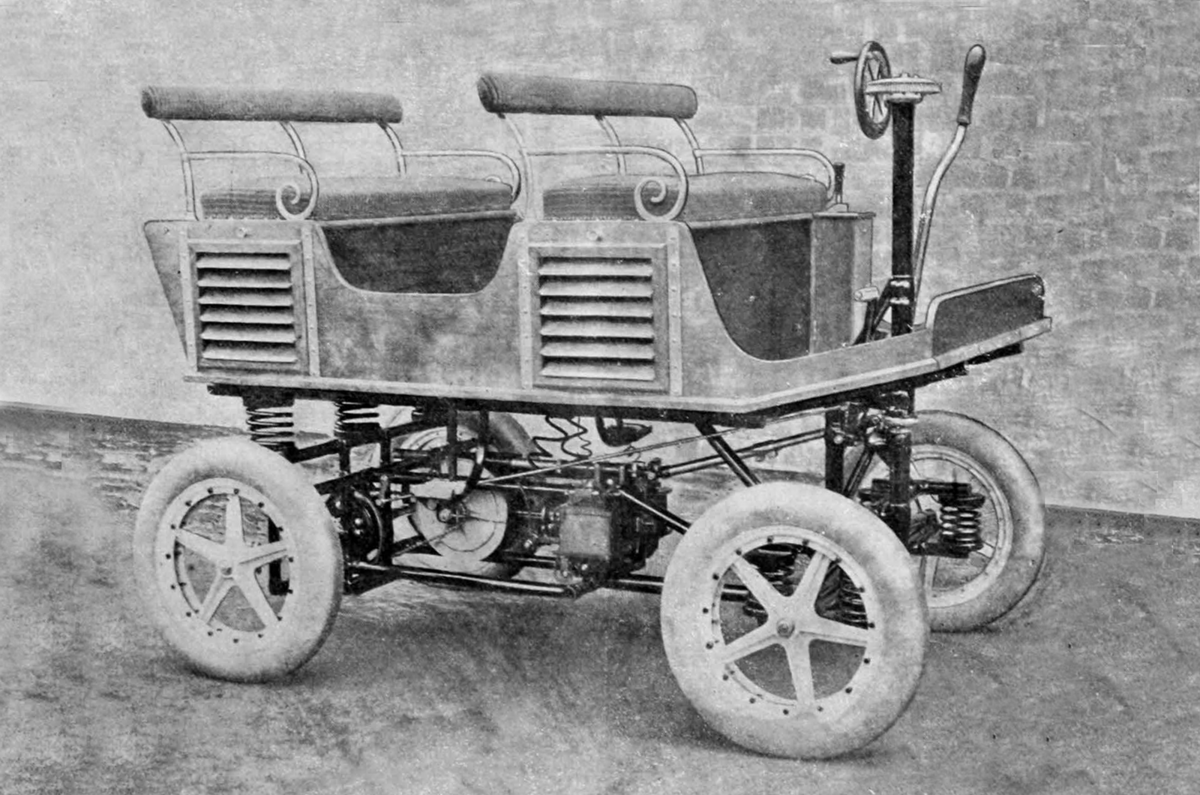

Produced by the Garrard & Blumfield bicycle engineering company of Coventry, it was a four-seat phaeton with an innovative drive system.

“We understand that Messrs. Garrard and Blumfield hold a master patent for the known elements of (I) pneumatic tyres, (2) balance gear, (3) steel tubing, (4) ball bearings; and (5) electric power,” we began.

“The mechanism of the carriage and its framework are built throughout of weldless steel tube, the general design of the frame being not largely dissimilar from that adopted in the Rudge quadricycle of a year two back.

All four of the phaeton’s wheels were 24in in diameter and shod in 4in pneumatic tyres. As with all other working parts of the vehicle, they ran upon ball bearings.

“The front two wheels are steered by means of a long ball socket head, actuated by a wheel and tangent screw,” we explained.

The electric power unit for the Garrard & Blumfield was “contained in a series of twenty-four accumulator (rechargeable) cells”. These were likely lead acid, although we could not find any writing confirming this.

“The accumulators (batteries) weigh some 500lbs,” we continued, “and the completed vehicle comes out at about 1000lbs, or, roughly speaking, about half a ton, as against two and a half tons the weight of the lightest electric road carriage hitherto placed upon the road.”

The phaeton’s “cells were connected with a motor carried upon the (car’s) framework beneath; the spindle which the motor works, being arranged with a feather, so that it can be slid to and fro several inches by means of a lever, placed in contiguity to the rider’s left hand.”

“This is effected by quite a new system,” we said, with “the spindle carrying a roller or a pair of rollers so arranged that they jamb between the surfaces of two metal discs which face each other in the rear portion of the carriage.

“By sliding the roller in or out from the centre of these discs, the power applicable, and inversely the speed attained, is graduated to the nicest degree. The discs are then connected by toothed gearing and a chain with the balance gear which drives the two back wheels.”

This method, instead of finding a way to modulate the available power, “saved a tremendous waste of electricity”.

As with modern electric cars, such as the Tesla Model S, which is built upon a ‘skateboard’ chassis with battery packs incorporated, any body could then simply be placed on top of this mechanism. In the prototype we reported on, this was of two forward-facing seat benches behind one another at the same height.

“A very powerful band brake acting on the balance gear is worked by a foot lever placed conveniently to the right foot of the engineer,” who sat on the left of the car.

Performance was quite impressive, the car “being calculated as able to run at speeds varying from 3½ to 13½mph, according to the gradient over which it is running, or the wish of the occupants.”

Join the debate

Add your comment

Hmmm...

Isn't the average speed in London

80 mile range

110 years

brian245 wrote:

Like xxxx said, you're not comparing like with like - nobody today drives anywhere at 10 mph, and no mainstream car weighs half a tonne. It's very hard to find energy figures for electric cars, but this probably stored less than 5 kWh, whereas modern EVs store 24-100.

People have managed to eke nearly 200 miles from a 2013 Leaf, and that's with three times the weight and at several times the speed.