Despite the almost bewildering progress of technical innovation, there are many fundamentals that have been around for a very long time.

Hydraulic brakes were introduced in the US at the end of World War One. Since then, they have evolved beyond measure, with better design and materials and features such as power assistance and ABS. But according to ZF Friedrichshafen, which has produced more than three billion brake components in the past three years alone, hydraulic brakes’ days are numbered.

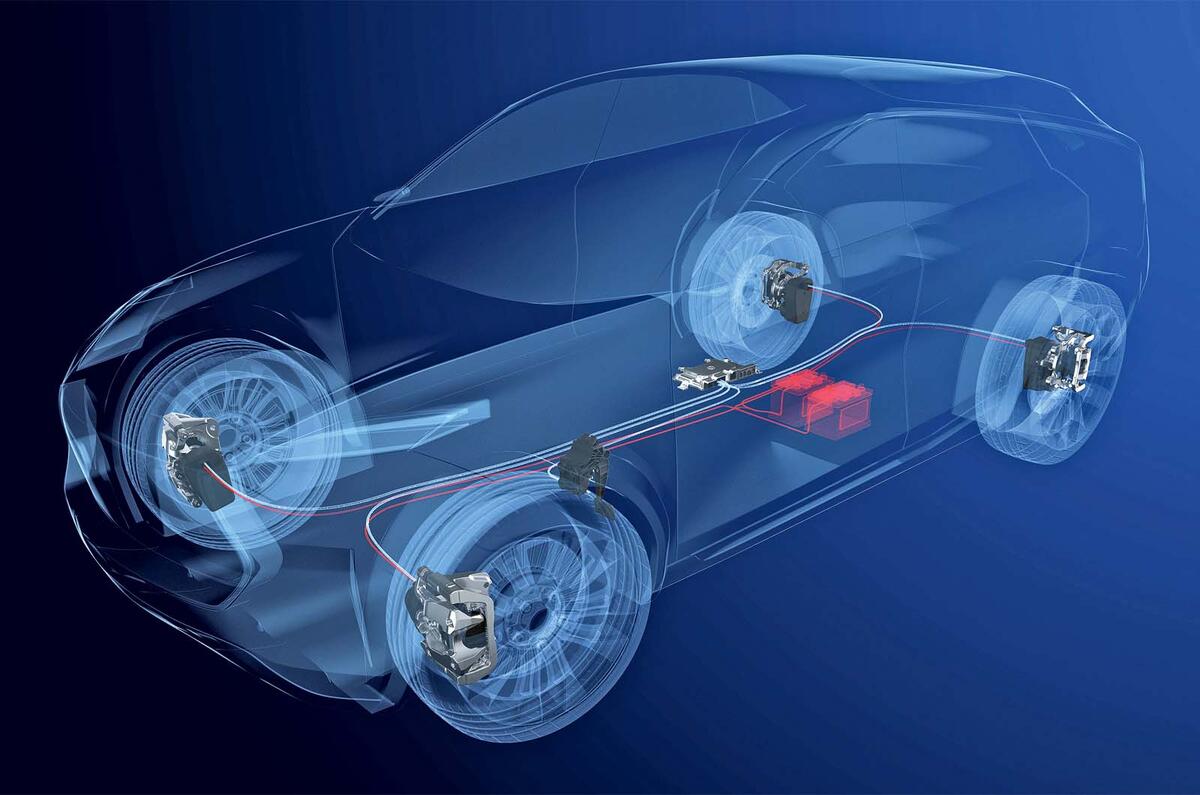

Given the advance of automated driving features, electrified drivetrains and networking of chassis systems, the component supplier says the switch to brake-by-wire (BbW) is inevitable. The ‘dry’ braking tech is already gaining a foothold both as full four-wheel systems and as ‘hybrid’ set-ups that combine both BbW and hydraulics and are aimed at light commercial vehicles.

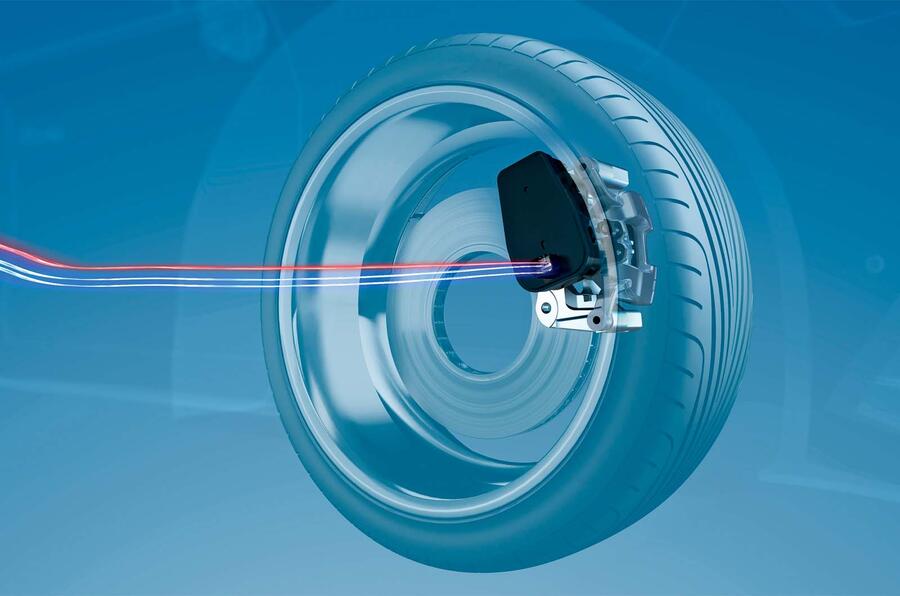

With BbW, the pressure generated for brake pads to grip discs is no longer generated by a force created by the driver pressing on a pedal, but by electric motors in each caliper. An electronic pedal box measures the force applied to the pedal, and the electromechanical brakes (EMB) are applied electrically.

ZF says EMBs are more responsive in highly dynamic situations, such as simultaneous braking and steering, and they enable optimised recuperation in electric cars. With the increase in weight of modern cars, engineers say it’s important that brake pressure is built up as quickly as possible, and this is what by-wire systems are good at.

Other advantages include reduced maintenance costs (no brake fluid to deteriorate and be replaced) and no spectre of failing hydraulic cylinders and brake lines as vehicles age. Residual drag torque – drag caused when the brake pads don’t retract fully and rub on the discs – is almost zero.

This is something that, as a car ages, becomes an unseen parasite eating into fuel efficiency and, in EVs, battery range. There’s also the fact that hydraulic brake fluid is messy, unpleasant stuff, and most types are corrosive to paint if spilt. They’re also hygroscopic, absorbing water.

That said, ZF is producing two systems: complete four-wheel BbW aimed at passenger cars and, for the US market in particular, ‘hybrid’ systems for use on heavy-duty light trucks. These are simply a combination of EMBs on the rear axle and hydraulic brakes on the front.

On heavier vehicles, the usual electric parking brakes can’t apply enough force to reliably hold the vehicle, whereas EMBs used in BbW systems can. The rear EMB also neatly doubles up for both normal braking and parking.

Join the debate

Add your comment

Nice post.

Fascinating read — the shift to Brake-by-Wire really could mark the beginning of the end for conventional hydraulic systems reliant on brake fluid. With electric-caliper actuation and electronic pedal sensing, the drawbacks of fluid degradation, moisture absorption and messy maintenance could become a thing of the past.

And with the shift towards electrification and availability of cheap and powerful electric motors, shouldn't t the emphasis be on maximising braking via energy recovery, leaving the friction brakes as an emergency back up and handbrake? Such an arrangement would make front or 4WD the preferred arrangement, since energy recovery via the rear wheels alone would be limited.