They say Le Mans is won and lost depending on how much time a car spends in the pits. That places special demands on the consumables of each racing car in the field.

Originally, tyres were changed at every fuel stop but it became apparent that a competitive advantage could be gained by tyres being used for more than one stint.

In last year’s 24-hour race, some competitors were able to use the same set of tyres for four successive 90-mile stints, even in the intense heat of the afternoon when the rubber runs at its hottest temperatures.

Spending less time in the pits than its rivals contributed to the Dunlop-shod Jota team winning the LMP2 category. Remarkably, this occurred in tandem with very little drop-off in performance: Dunlop’s engineers calculated that the lap average for fourth stints on the same tyres was 0.17sec slower than the average for stints when the rubber was fresher.

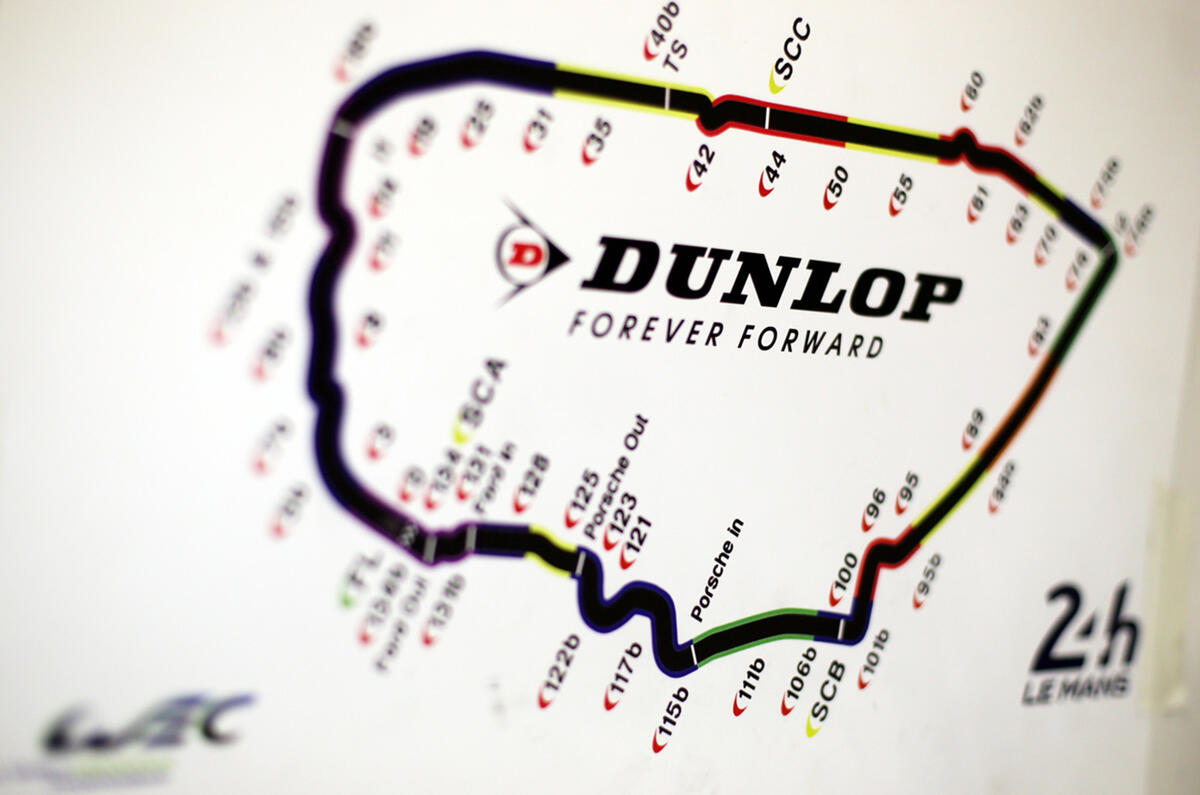

“The nature of the Le Mans circuit is completely special,” says Matthew Rees, service engineer for Dunlop Motorsport with responsibility for the G-Drive Racing team’s Ligier-Nissan.

“It has a multitude of track surfaces, from the permanent race track to the public road section. You also have to take into account factors such as race debris, oil and deposits dropped from normal road cars on the public road section. In all, the demands on the tyres are fairly high.”

At the start of the World Endurance Championship season each tyre manufacturer has to submit its compounds to the rule makers at the ACO.

“At the moment Dunlop has the soft, the medium and the medium plus, in addition to intermediates and wets for inclement weather,” says Rees. “A range of teams will be using the three variants across the whole of the Le Mans 24 Hours.”

Each LMP2 car has 16 sets of tyres at its disposal during the race. The performance of Le Mans prototypes can evolve dramatically during the course of the 24 hours. Britain’s Sam Bird, who shares the G-Drive Racing entry with Julien Canal and Roman Rusinov, says the opening stints of the race will be crucial in understanding more about the level of tyre wear.

“We had restricted running in both test days, so we’re actually a little unclear on the exact life the tyre has. We know that it is long, but we don’t know precisely how long,” he explains.

“So at the beginning of the race we will probably do a double-stint and then change tyres so the guys at Dunlop can examine the rubber and give us an exact reading on exactly how far they think our tyre will go while maintaining a good speed.

"After we’ve found that information out, our pitstop strategy for the rest of the race will be more dictated by fuel rather than the tyres.”

There are also some techniques the driver can use to preserve the rubber for as long as possible. Bird says: “We speak about ‘spin time’, which means trying not to overwork the [driven] rear tyres. But because of the long straights at Le Mans, the tyres get to cool down quite a bit on each lap.

“Another thing that we could see from the front tyre during the race is some cold graining, especially between 2am and 7am in the morning.

Add your comment