Audi is predicting the end of the conventional production line, which will be replaced by a new modular assembly method.

The shake-up will be a remarkable change for an industry that has been organised around a fixed production line every since Henry Ford created the Model T over 100 years ago. The modular system will be introduced on Lamborghini Urus production in Italy. An approximate timeframe is "major change within 10 years", according to Audi officials.

"Audi is convinced that the assembly line has had its day, because as model diversity grows, the more complicated it becomes to master complexity in a rigid sequential process," says the company.

The push is being accelerated by the shift to electrified powertrains, which require cars to be taken onto a spur, built alongside the conventional production line, where electric motors and batteries are fitted.

"The conventionally powered cars are not worked on during this time, so the time until completion becomes longer for all the cars on the line," says Audi.

“While this is going on, its sister models with conventional drive move along the conveyor belt suspended below the ceiling,” says Audi.

A plug-in Audi A3 Sportback e-tron passes through seven separate workstations for its electrical powertrain, through assembly stations that internal combustion-engined A3s don’t pass through.

While the e-tron is being made, the conventional Audi A3s can’t progress down the production line.

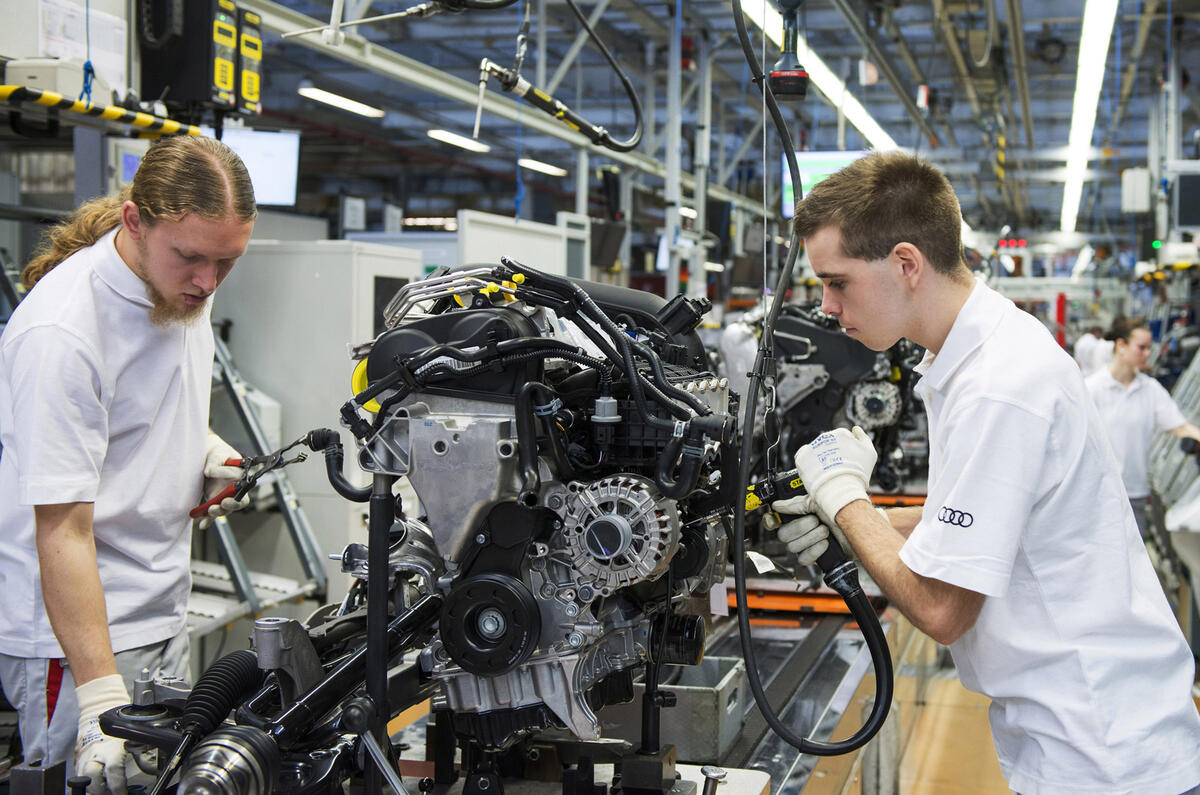

Instead of a production line, Audi will break assembly down into individual work areas, staffed by one or two workers.

Audi says their workload can be better managed to even out the workload.

“They work steadily at a continuous pace, because they no longer have to adapt their activities to the speed of the line,” says Audi.

To move cars between the modular workstations, Audi envisages a fleet of automatically guided vehicles, matched to smaller ‘driverless transport systems’, to supply components just in time.

Join the debate

Add your comment

Keep them there

A lot of stupid snide

A lot of stupid snide

Coloured view