Revolutionary British-designed premium car audio technology with the potential to bring huge improvements to both on-the-move listening experiences and overall car efficiency is soon to be launched by a Midlands company that was spun out of Warwick University’s engineering department 20 years ago.

The company, Warwick Acoustics (WA), has headquarters at the MIRA Technology Park near Nuneaton and it bases its revolutionary business on the development of electrostatic speakers that are smaller, lighter, higher performing and easier to package than any existing conventional speakers for cars. In addition, WA – which also develops accompanying software for its systems – claims powerful advantages in sustainability for the trailblazing new products, due to be revealed in a prototype vehicle soon.

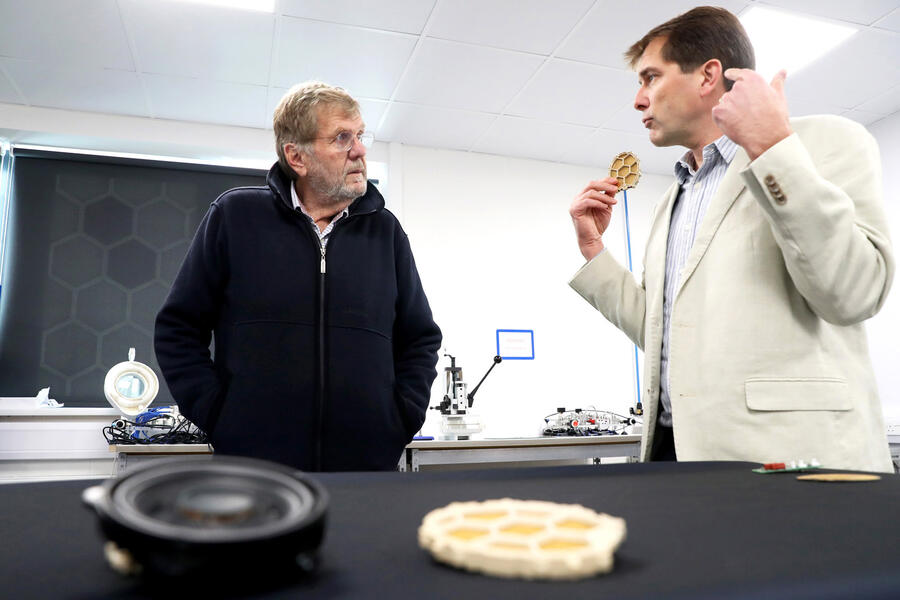

WA’s managing director is Mike Grant, who was drafted in by the company’s investors in 2015 to assess its potential. The firm had harboured its highly promising audio technology for about 10 years but done little to move towards production. Grant says his first job was “to decide if the company’s technology had a production future”. He soon recognised that although electrostatic speakers weren’t new in principle, WA’s unique ‘take’ on them made them especially suitable for cars and e-technology. He reckoned that with the right kind of development programme, they could become “classic disruptors” in a global market for around 500 million car-based speakers a year, currently worth around $8 billion (£5.9bn).

He set out to adapt WA’s technology to all kinds of cars but now believes its arrival will be perfectly timed to enhance the new generation of electric cars in which weight is absolutely critical and whose different cockpit layouts offer bold new packaging opportunities. What is more, their innate quietness will provide a listening environment for sophisticated audio that is closer to the ideal.

Previous electrostatic speaker designs were too delicate and difficult to power to survive in the tough automotive environment, says Grant. But by combining WA’s original university-developed intellectual property with more recent fruits of its R&D, and with help from recent developments in materials science, WA was able to start developing products that are durable enough for road cars and e-mobility applications. WA moved into its current MIRA premises in 2018 with just five employees. By the end of 2020, it had a team of 15, and by the end of this year, it’ll be 50.

Previous electrostatic speaker designs were too delicate and difficult to power to survive in the tough automotive environment, says Grant. But by combining WA’s original university-developed intellectual property with more recent fruits of its R&D, and with help from recent developments in materials science, WA was able to start developing products that are durable enough for road cars and e-mobility applications. WA moved into its current MIRA premises in 2018 with just five employees. By the end of 2020, it had a team of 15, and by the end of this year, it’ll be 50.

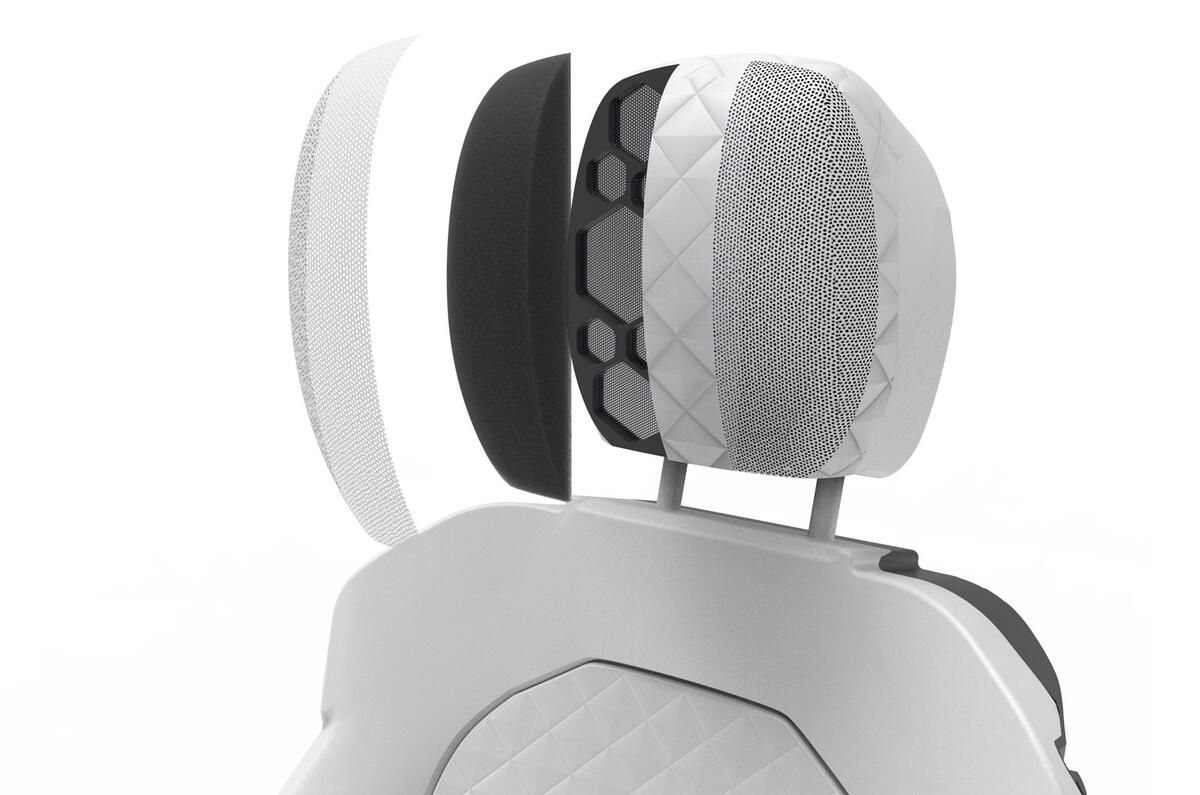

An electrostatic speaker uses very different technology from the conventional circular or oval types we’re used to. Whereas conventional speakers have a relatively bulky and heavy moving magnet to activate a diaphragm that moves air and thus creates sound, an electrostatic speaker has an extremely thin multi-layer membrane sandwiched between two electrically conductive stators. The audio signal is applied across the stators to vibrate the membrane and produce sound – which is usually more detailed because the membrane is very light and responds more quickly to inputs.

These were primarily intended for use by recording studio engineers but have since been embraced by discerning audio enthusiasts, have won more than 30 awards and are widely acclaimed as “the best headphones money can buy”. They should be good, mind. The ultimate model, called Aperio, is hand manufactured in gold, comes with a custom amp and sells for a cool £30,000 – only in Harrods. This perhaps gives us a helpful clue to the automotive sector WA will initially target. “We won’t be putting our equipment in Ford Fiestas for the time being,” says Grant.

These were primarily intended for use by recording studio engineers but have since been embraced by discerning audio enthusiasts, have won more than 30 awards and are widely acclaimed as “the best headphones money can buy”. They should be good, mind. The ultimate model, called Aperio, is hand manufactured in gold, comes with a custom amp and sells for a cool £30,000 – only in Harrods. This perhaps gives us a helpful clue to the automotive sector WA will initially target. “We won’t be putting our equipment in Ford Fiestas for the time being,” says Grant.

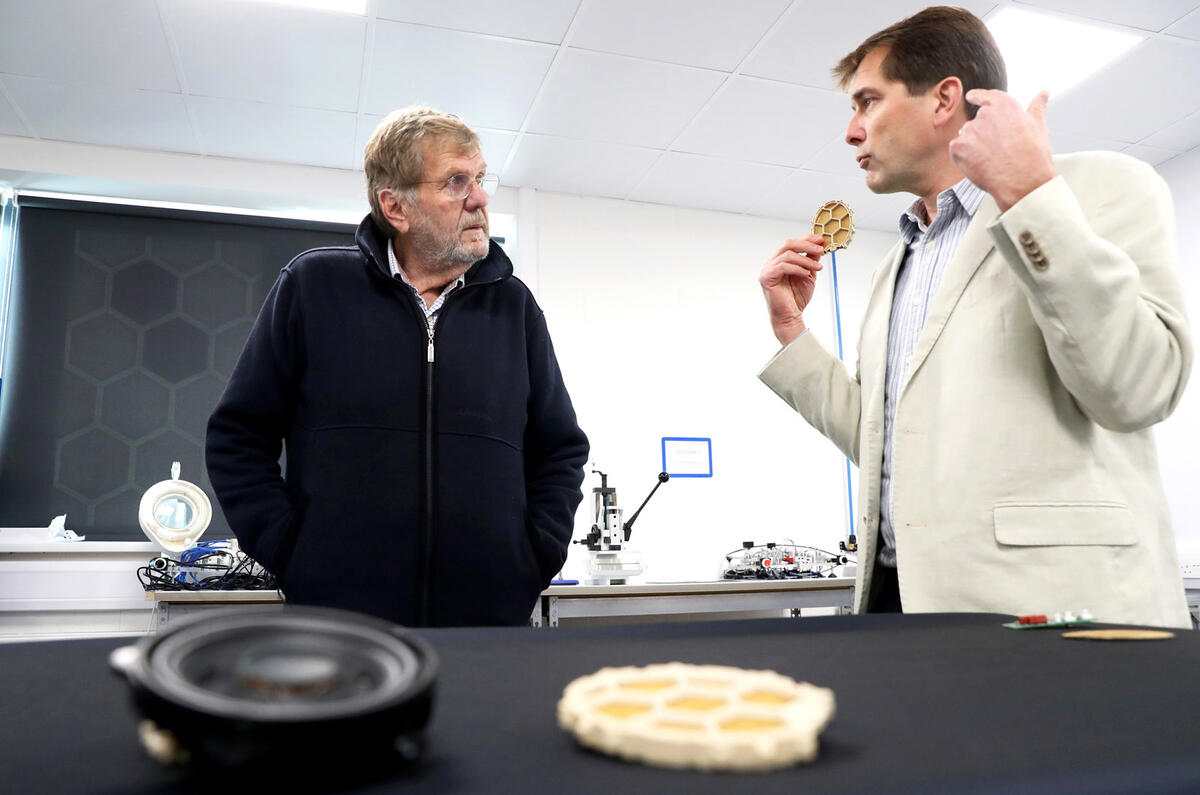

The basis of WA’s automotive sound revolution – the electrostatic transducer – looks almost too simple and small to be a disruptor, especially against a conventional cone speaker with its relatively heavy central magnet and fragile diaphragm. But just by handling one, you can appreciate WA’s claim for light weight and easy mounting.

The basis of WA’s automotive sound revolution – the electrostatic transducer – looks almost too simple and small to be a disruptor, especially against a conventional cone speaker with its relatively heavy central magnet and fragile diaphragm. But just by handling one, you can appreciate WA’s claim for light weight and easy mounting.

Join the debate

Add your comment

Fascinating stuff indeed, but for someone like me who is Deaf in one Ear the tech won't improve my enjo because I'll never know what it really should sound like.