In the quest to reduce weight, one area of a car’s structure that gets relatively little public attention is seating.

As drivers and passengers, we probably take them for granted beyond how comfortable or not they might be. But if you’ve ever had to remove a seat from a car, you’ll know just how complex and heavy they are. Seat makers already employ lightweight steels and aluminium but we could soon see much more advanced methods of construction to save weight and greater use of sustainable materials.

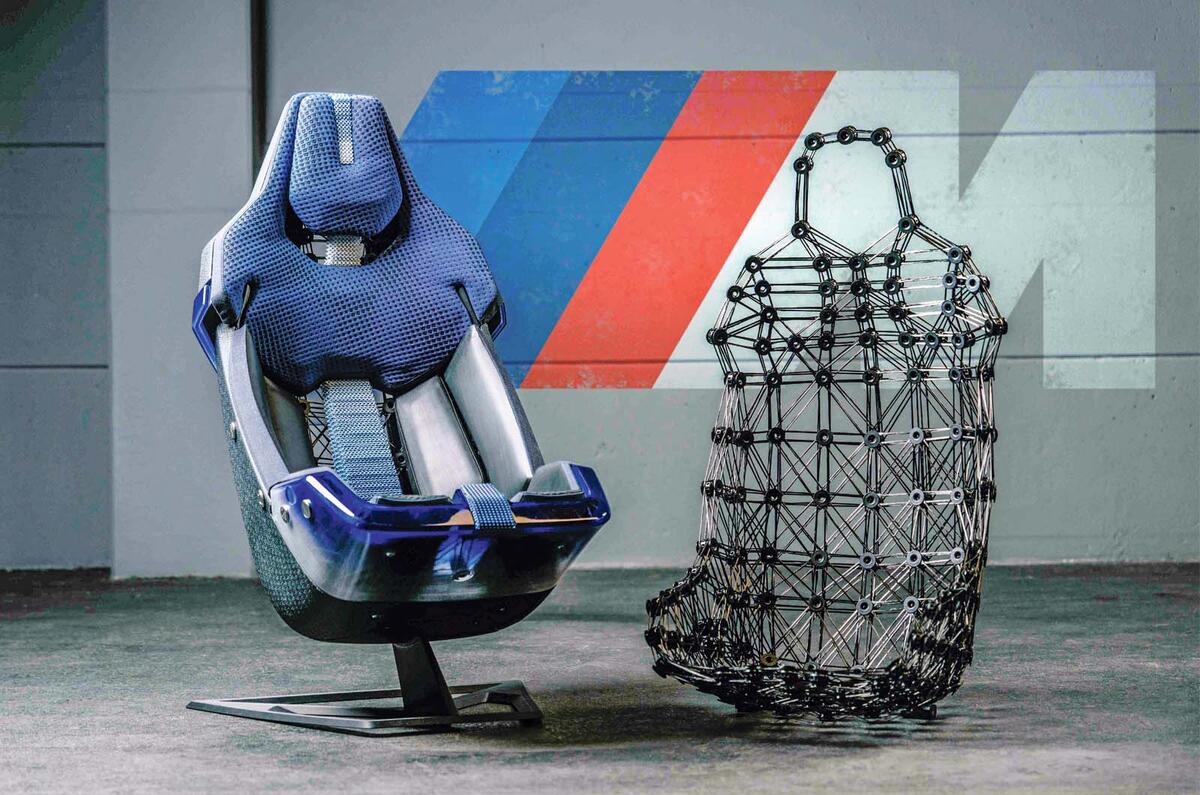

For instance, BMW revealed its M Visionary Materials seat, a project to explore the use of recycled and plant-based raw materials and bio-based leather alternatives. More on that in a moment.

What we see on the outside of a seat is just the proverbial tip of the iceberg. Inside lie complex structures, electrics, heating and ventilation and sometimes safety-related technology such as airbags.

A typical seat comprises a frame for the base and another for the backrest. It has to be light but strong enough to resist a crash and take up as little space as possible while being comfortable. Naturally, cost is always a consideration.

According to Thyssenkrupp, which supplies a range of specialised lightweight steels for seat structures, the steel frame of the average front seat structure alone can weigh 12.5kg and, added together, the total for the front and rear seats is around 50kg.

The industrial technology company says its lightweight steels can make a 15% reduction compared with using non-lightweight materials.

On top of that, there’s base and backrest foam, headrests, lumbar support adjusters, recliner mechanisms, height adjusters and maybe heating and air conditioning, making seats hefty objects.

In the past, Toyota has experimented with 3D printing of seat structures and in 2021 Porsche developed a 3D-printed bodyform full bucket seat.

Back in 2017, Braunschweig University of Art students in collaboration with Audi produced Concept Breathe, a 3D-printed rethink of the car seat with a plastic biodegradable plastic skeleton structure on which were mounted 38 active cushions.

BMW’s seat takes a completely different approach. Its structure is built using robotic filament winding courtesy of Luxembourg-based specialist Gradel Light Weight. The structure is created by a robot applicator winding thread-like filaments mixed with resin around a network of bobbins mounted at key points around the structure.

Gradel says the structure is as strong as any using conventional materials but 60% lighter and BMW describes the technology as the “catalyst” for the project in that the technology completely does away with conventional structures.

Weight was saved by reducing the number of parts – and the seat looks extremely cool too.

Join the debate

Add your comment

Pls could you never, ever, ever, ever use the term "lightweight steel" again!!! Steel is steel, 7900kg/m3. There's higher grade versions which might enable you to use thinner steel but the density is the density.

Much appreciated :-)

Is this Christmas Eve or is this April Fools Day.

Know what you mean truely shocking how heavy a seat can be. Aircraft manufacturers did this some time ago and not only are the seats much lighter their volume has been reduced too.

Trouble is we humans are getting bigger and there only a limit to how small seats can be. Merry Christmas!