When a company the size of Bosch is poised to release a new technology, it’s usually something to take seriously. Tier-one suppliers like Bosch are at the top of the supply chain to the automotive industry and are responsible (rather than the car manufacturers) for introducing much of the technology that makes all vehicles tick.

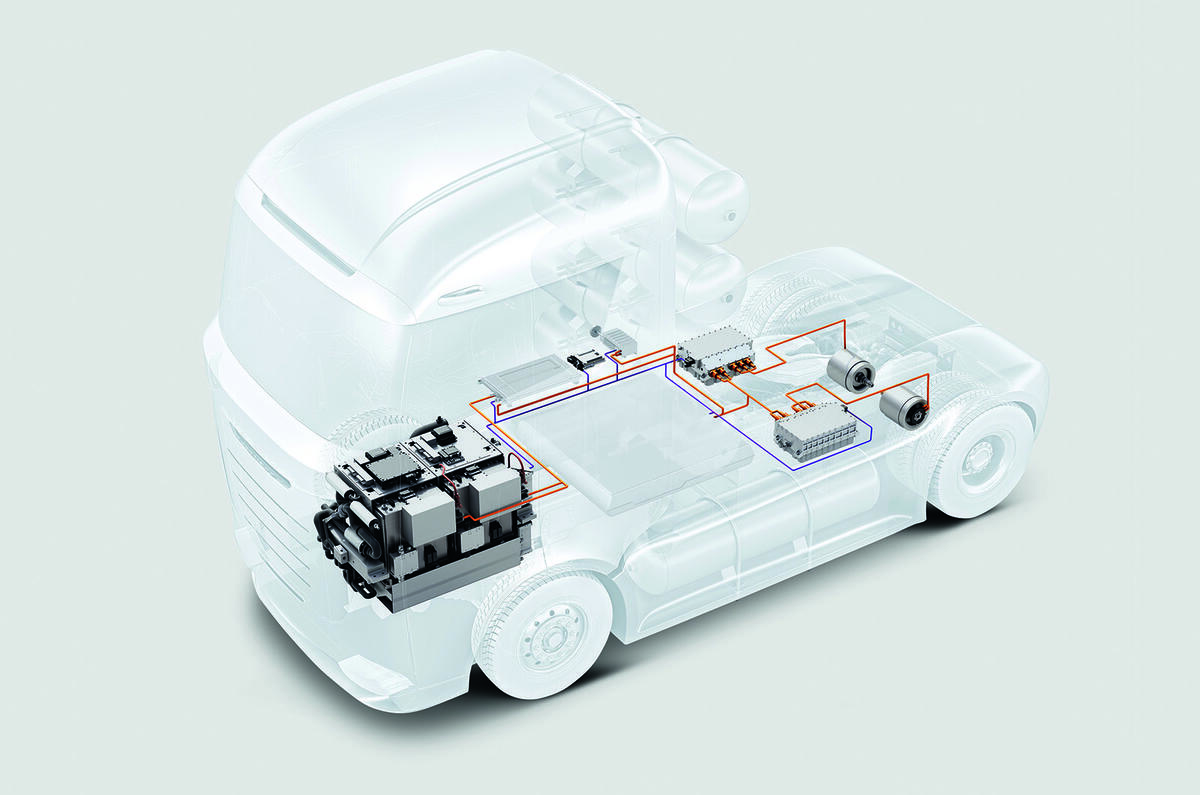

Bosch recently announced plans to start production of hydrogen fuel cell powertrains between 2022 and 2023, focusing initially on trucks. Once these are established in heavy vehicles, smaller-scale versions for cars can follow. Fuel cells convert hydrogen and oxygen from the air to electricity, heat and water, and using hydrogen produced from renewable energy makes the operation of a fuel cell vehicle carbon-neutral. Heavy trucks are a good starting point for the technology because batteries big enough to provide sufficient range would be huge in volume and weight, not to mention incredibly expensive.

Hydrogen has a high energy density and, because it’s stored as a compressed gas in a fuel cell vehicle, its quantity is measured by weight, rather than volume. One kilogram of hydrogen contains about the same amount of energy as 3.3 litres of diesel. Bosch calculates that 7kg of hydrogen is enough to power a 40-tonne truck for around 60 miles. That means 35kg of hydrogen would be good for 300 miles.

Given that the battery in a premium electric car today can weigh more than 500kg, it doesn’t take much imagination to work out that a truck battery capable of doing the same would be huge – unless there’s a radical improvement in the energy density of current battery technology.

There’s plenty of debate about the efficiency of hydrogen fuel cells compared with batteries, and there are two conflicting schools of thought. One is that feeding electricity (an energy source) straight into a battery is more efficient than converting it into hydrogen (an energy carrier) then back into electricity. The other, to which Bosch subscribes, is that electricity production and demand rarely coincide, so making hydrogen on a decentralised basis to store, rather than waste, surplus electrical energy makes the case for fuel cell vehicles. Bosch believes that hydrogen costs will fall in the medium term in order that running a fuel cell vehicle will be no more expensive than one with a conventional powertrain.

Tests over the decades have demonstrated hydrogen to be safe compared with liquid fuels, too. Hydrogen is 14 times lighter than air and volatile. In the right proportions, a mixture of hydrogen and oxygen can be explosive, but when hydrogen escapes from a vehicle, it rises too quickly to react with oxygen in the air. Hydrogen fires can be over in a flash and might not do much damage, whereas heavier-than-air, ground-hugging petrol fumes can easily cause explosive fires.

Fuel cell vehicles share pretty much the same electric driveline with battery-electric vehicles, so with a combination of both hydrogen and battery technologies, vehicle manufacturing could become more streamlined and increasingly sustainable.

Batteries in the afterlife

Join the debate

Add your comment

Weight

There's an interesting case study on hydrogen vs electric trucks here if anyone's interested:

transportenvironment.org/sites/te/files/publications/2020_06_TE_comparison_hydrogen_battery_electric_trucks_methodology.pdf

There's a falacy here that crops up a lot when comparing these vehicles. If you're weighing *just* the hydrogen, it's like weighing *just* the lithium ions in a battery. The hydrogen itself comprises a tiny fraction of the weight of the powertrain: the heavy parts are the storage vessel (armoured, chilled, pressurised, anti-embrittlement, lots of sensors), the fuel cell stack and the buffer battery/supercapacitor. If you're looking at cars, the majority of battery-electric vehicles are lighter than fuel cell vehicles, even some with equivalent range and size.

However, an FCV's weight is separated between energy supply (storage vessel) and power generation (fuel cells and buffer), whereas in a BEV they're both lumped together in the battery. This means that in applications that need a more divergent ratio of energy : power, you can enlarge those components separately, and potentially end up with a lighter vehicle than a pure-electric version. In cars the ratio favours BEVs, but in really high-energy applications such as long-haul trucking, shipping and aviation, FCVs probably have the advantage. Can't say exactly how much, because there aren't many real-world like-for-like examples to compare right now, whereas there are for cars. But that's the theory, at least.

Hydrogen

Actually there's no debate, hydrogen is not as efficient as electric and it's by a long way. Other than that trucks are hydrogens only chance as a fuel and even then its waffer thin

Efficiency is not the only consideration

As with all engineering solutions, there will always be many often conflicting aspects to juggle with, so that efficiency would be a major but not the only consideration. The fact that an electric truck would need such an enormous battery, no matter how efficient, is a case in point. From what I've read, it would appear that hydrogen fuel cells will be the answer for the heavy stuff, from large SUVs upwards; there are prototype fuel cell trains currently being developed. A lot will depend on how and how quickly a hydrogen supply infrastructure is constructed.

The benefit of rolling it out

The benefit of rolling it out in trucks first is you can build minimal infrastructure in strategic locations on main routes. You won’t need multiple filling stations in every town and city right away. As the current fleet of trucks are then phased out over the next two decades then that will give plenty of time to build a filling network.

The next big hurdle I see is producing hydrogen cheaply and greenly as I believe current industrial hydrogen is a dirty chemical process. We need to move to an industrial version of electrolysis, the same as in school science class. If only there were some countries near water that had plentiful amount of sun all year round that were running out of oil.

xxxx wrote:

I remain unconvinced by fuel cell cars, but hydrogen fuelled trucks, ships and planes? Yes, I think so... particularly planes, which are unlikely ever to be viable as EVs and cause enormous pollution.

Ignorance is Bliss, Apparently

A year ago I thought the hydrogen revolution would be a 50-100 year transition. Now I'm thinking 25 - 50 years. The momentum that has built in the last 12 months, led by both public institutions and and private enterprise, has been surprising and hugely encouraging. I can't share details of the green hydrogen project we've recently started working on here in WA, but the scale is staggering. Only those with absolutely no undertanding of industrial sciednce and engineering continue to ignore hydrogen.