Jaguar Land Rover (JLR) is leading a consortium of academic and industry partners to research and develop lightweight composite materials for use in its cars.

Dubbed Tucana, it’s a four-year project aimed at making the UK a “world leader in low-carbon technology, helping prevent 4.5 million tons of CO2 emissions between 2023 and 2032”.

It’s also hoped that it will accelerate the uptake of electric vehicles.

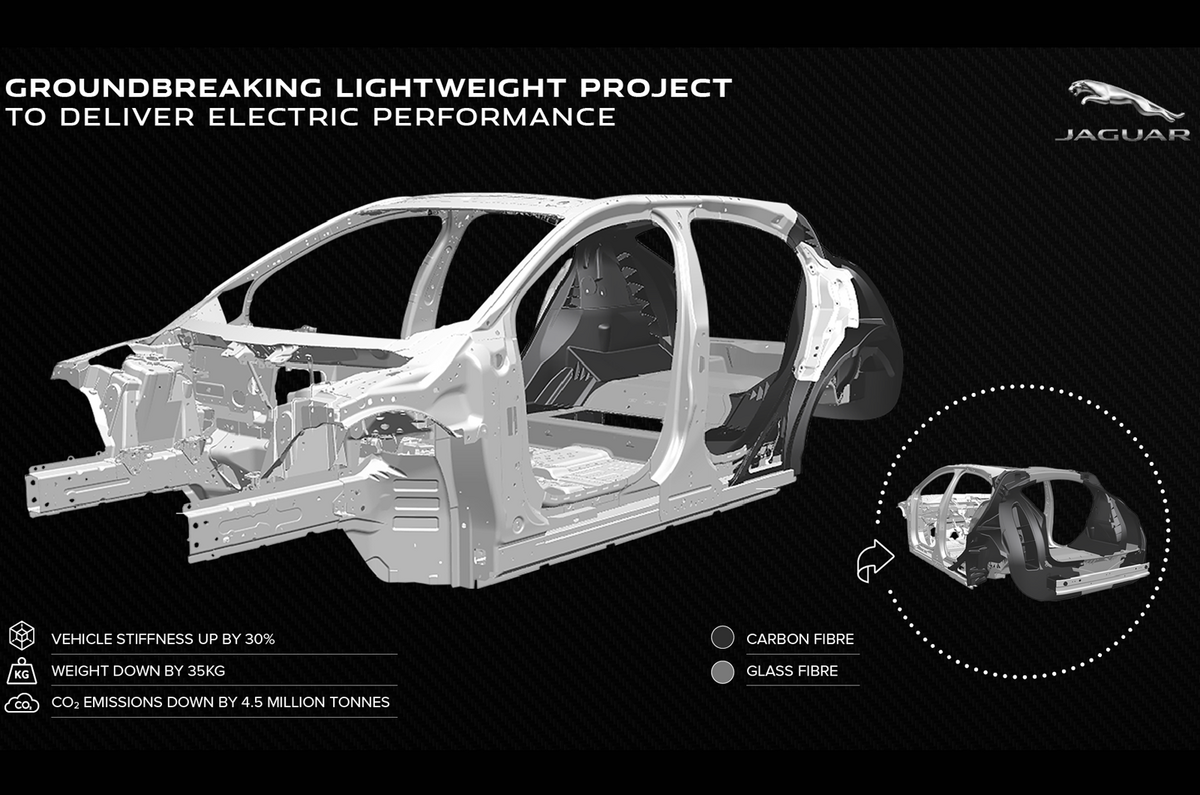

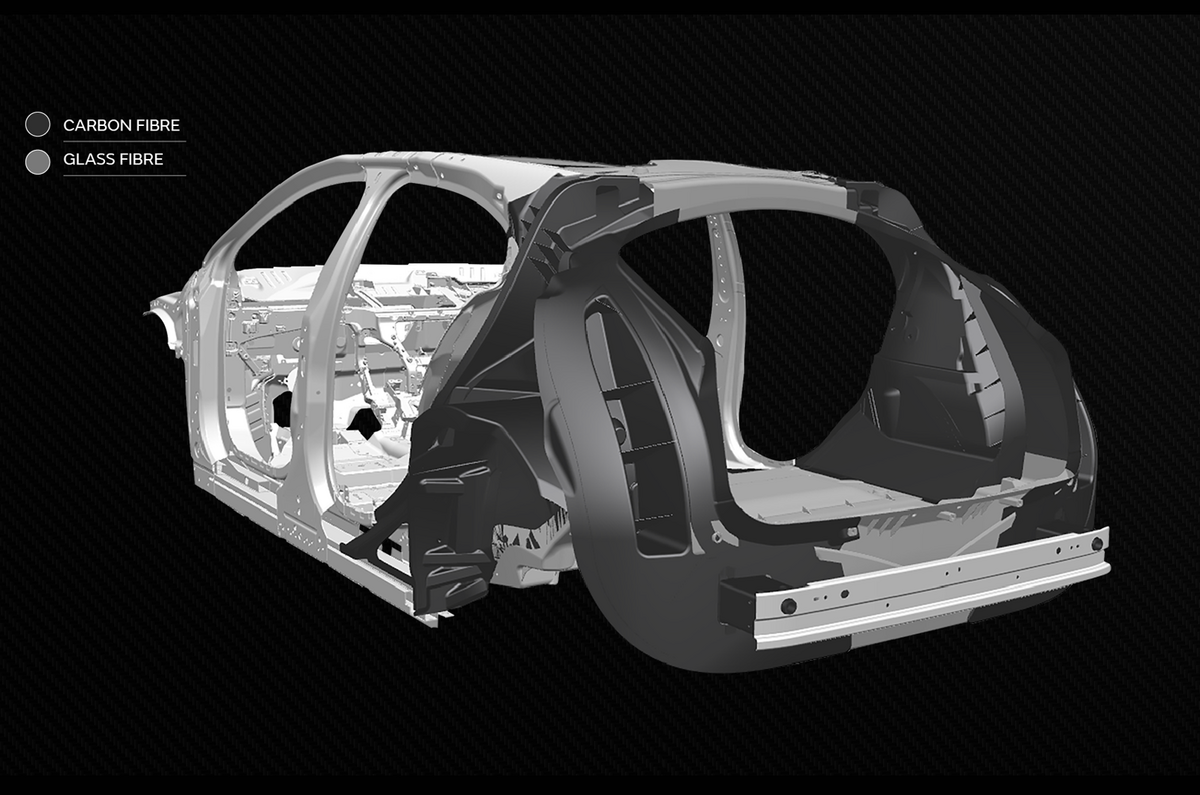

The British manufacturer wants to develop “lightweight vehicle and powertrain structures” to replace the traditional use of aluminium and steel. Composite materials will be tested to ensure they can handle the additional on-demand torque of an electric motor, with the ultimate aim of improving efficiency and reducing the environmental impact of production.

The objectives JLR lists for the project are to be able to increase vehicle stiffness from today’s levels by 30%, reduce the body weight by 35kg and improve crash safety through the use of tailored composites, such as carbonfibre.

By 2022, the company expects to have a fleet of Tucana prototype vehicles in place to test this.

Companies involved in the consortium include the Warwick Manufacturing Group (WMG), Expert Tooling and Automation, Today International UK, CCP Gransden and The Centre for Modelling & Simulation (CFMS).

CFMS chief technology officer Ian Risk said: “Tucana shows how new technology development can be optimised and accelerated with digital engineering. Using new digital design, development and manufacturing tools helps to deliver emissions reduction faster so the UK economy can reach zero emissions quicker.”

Last October, JLR announced a similar, two-year project researching how innovative metals and composite materials respond to harsh or corrosive environments in a 250,000-mile testing regime across North America.

READ MORE:

Under the skin: how carbonfibre is trickling down to the mainstream

Lighter cars possible thanks to tech from Israeli firm

Jaguar Land Rover sales fall by a quarter in 2020 due to the pandemic

Join the debate

Add your comment

Right , four negative posts, would you spend millions on something that might be beneficial to all present and future car owners, if, someone had cracked it already?, it's not a miracle, it's allegedly going to remove up to 35kg of weight, so, making the battery bigger would?, what if batteries get lighter?, would making the car body lighter be good?, or would both be good?

Didn't BMW pioneer the use of Carbon Fibre & Plastic re-inforced body parts foe EV's on the i3 & i8 in 2013? Interestingly BMW has chosen to replace these models with conventional steel/aluminium bodies.

Do body shells really need another 30% increase in stiffness? When each new version of a car is announced, it is always claimed to be substantially stiffer than its predecessor, so surely they are stiff enough already. A weight reduction of just 35kg hardly seems worth mentioning. I presume the real advantage of this new technology will be reduced CO2 emitted during production.