In Bentley Motor's wood shop, typical car production line sights, smells and sounds – machines, heat, buzzers and perhaps a whiff of oil – are supplanted by the sweet scent of exotic woods such as walnut, cherry and eucalyptus and a hushed ambience akin to a library.

Phil Gent is technical manager in Bentley’s wood shop and an expert in using the material in car production.

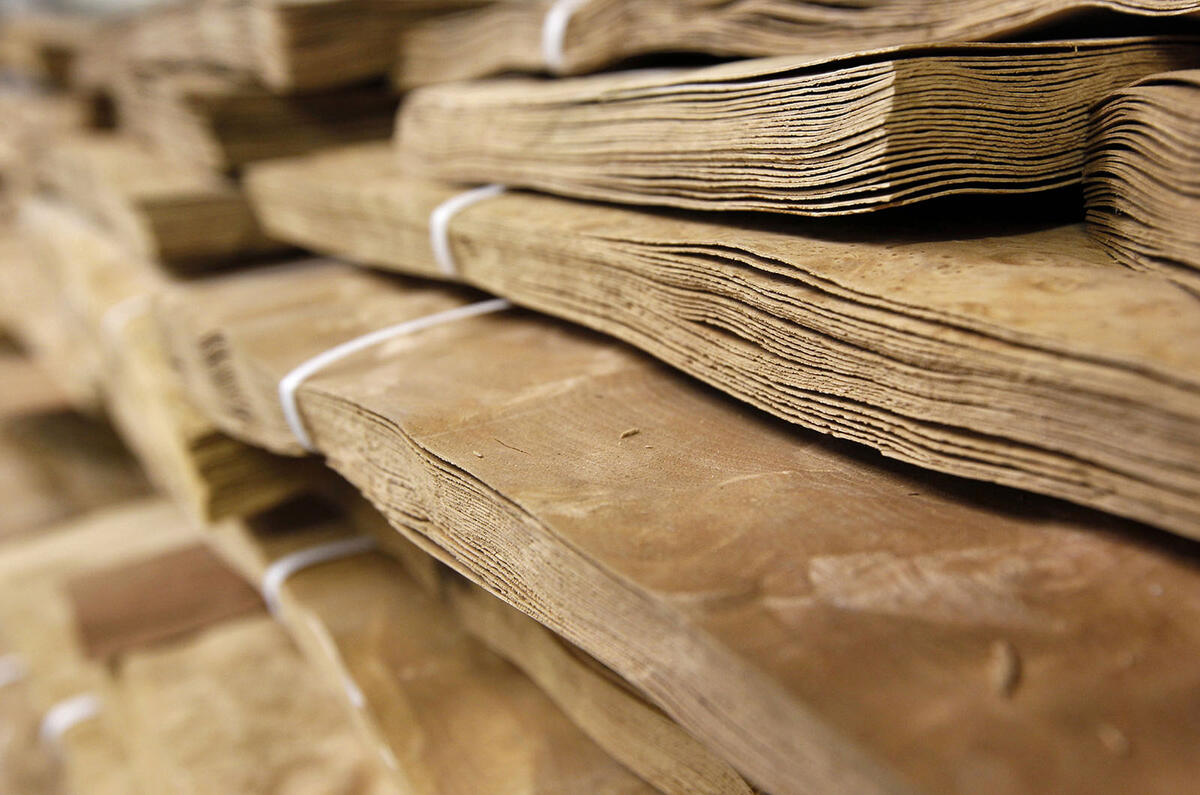

“Veneer is one of our key materials. It comes from a tree’s root ball underground,” he explains. “Our veneer supplier will dig it up, and soak it in a vat of chemicals and water for a number of days. It is then put on a circular lathe and the veneer is peeled off the root ball. The veneer comes off in random sizes. When we get it, it is sold in packs of 24 sheets.

“We use the root ball because that’s where the most decorative bit of the veneer is. So the older the tree is, the better for us. With young trees, you don’t get a lot of decoration and obviously you get less pieces of veneer because the root ball is smaller.

“Out of all the veneer produced in the world, we estimate that we’re selecting from the top five or ten per cent. There’s a lot of time, effort and money spend ensuring that the customer gets the best. When our storeroom is full we could have up to £250,000 worth of veneer in there.”

Bentley’s attention to detail means its craftsmen ‘match’ the patterns of veneer within a vehicle, so the driver and passenger will admire the same pattern in the wood in front of them in the car.

“This is really important in our car because if your eye goes to the centre of the car at the front instrument panel, and you work all the way around the car, you’ll see that there is a match all the way around the car,” says Gent.

The veneer is shaped using a laser cutter, and then bonded with laminates and other layers of veneer onto an aluminium substrate. The piece is then pressed at about 150 bar and a temperature of 140 degrees Centigrade for about five minutes.

Even if you specify a gloss black finish to your Bentley's interior, a layer of veneer is embedded underneath to ensure the thickness of the part is correct.

“After pressing we have a sanding operation,” says Gent. “It’s a little bit rough when it comes out of the press and you can feel the grain. We sand for two reasons: one, so you get a smooth finish and two, because it ensures that when we put the top coat of lacquer on, it sticks to the wood.

“It’s a polyester lacquer and we spray five coats on, which is about a two-hour process. We aim to put about 1mm of lacquer on the part.”

Then the part is sanded to remove any imperfections from the lacquer, polished, and is finally ready for assembly.

Join the debate

Add your comment

You mean its cheap laminate

Not exactly cheap...

I wouldn't call root ball veneer "cheap" myself - walnut root balls can cost the same as a well-specced Ford Fiesta, and higher still if there's demand for a particular pattern or unusual type of wood. It's the same process Rolls Royce use in their cars - what's good for the goose and all that...

"Which goes some way towards