Formula Student racing cars (also known Formula SAE) have become a hugely popular way for students to hone their automotive engineering skills before graduating to work at car makers, race teams or other specialist companies.

Ohio State University (OSU) in the American Midwest is home to one such team. But OSU students have also built something much, much faster.

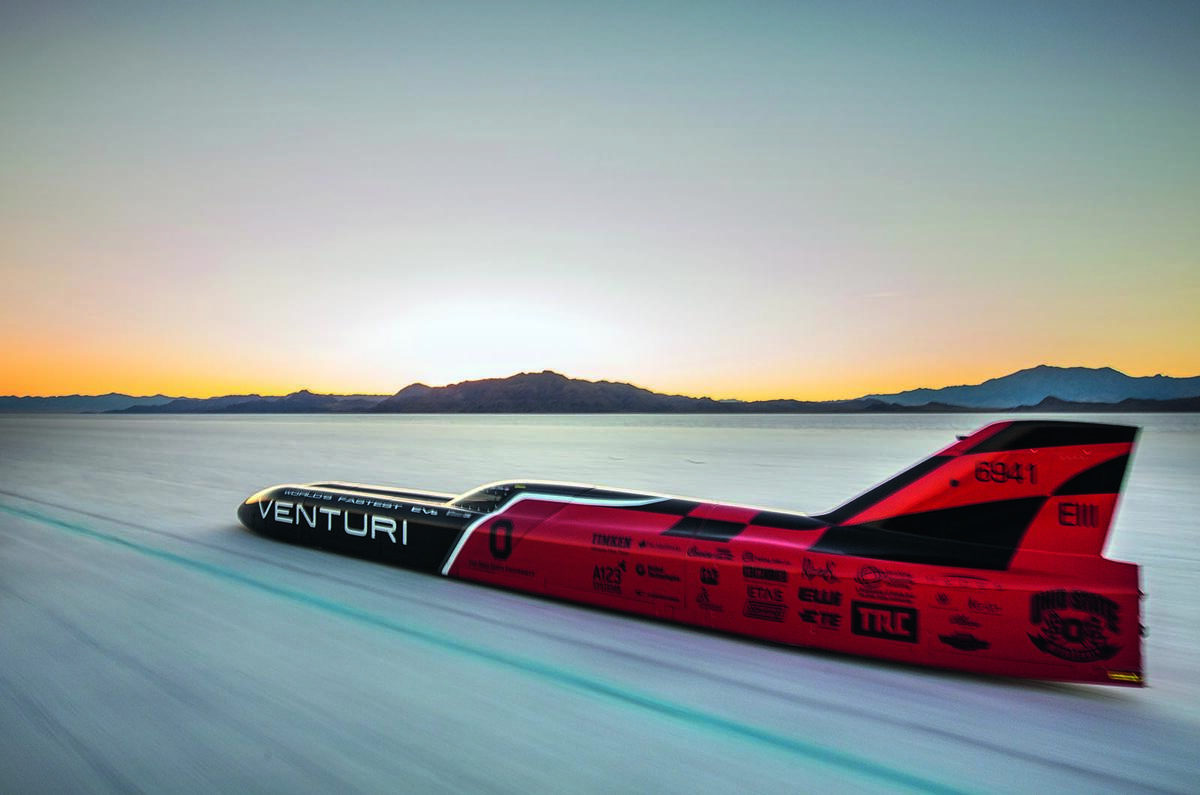

On 19 September, the Venturi Buckeye Bullet 3 (VBB-3) set an electric vehicle world speed record of 341.4mph (subject to FIA ratification) on the Bonneville Salt Flats. Perhaps more remarkable still was that the team broke its own record, set by VBB-2.5 (a battery electric version of the fuel cell-powered VBB-2), which clocked 307.6mph in 2010.

The Buckeye Bullet record programme dates back to 2004, when driver Roger Schroer took Buckeye Bullet 1, which ran on nickel metal hydride batteries rather than VBB-3’s 2000 lithium ion pouch cells, to a national land speed record with a 315mph average.

That year, the team enjoyed the best salt conditions seen at Bonneville for years. But since its debut at the Paris motor show in 2014, VBB-3 had been dogged by poor conditions on the deteriorating salt until a combination of dry and sunny weather, extensive surface grooming and luck – six inches of rain fell on the salt the day after the team packed for home – made this year’s record runs possible.

The students, who range from high-school interns to post-graduate researchers, had used the intervening time since 2014 wisely, making numerous detail improvements to their 11.6-metre-long EV. In particular, extensive work was done in the months leading up to this year’s Bonneville trip to automate and synchronise the gearshift, which is made using a steering wheel paddle.

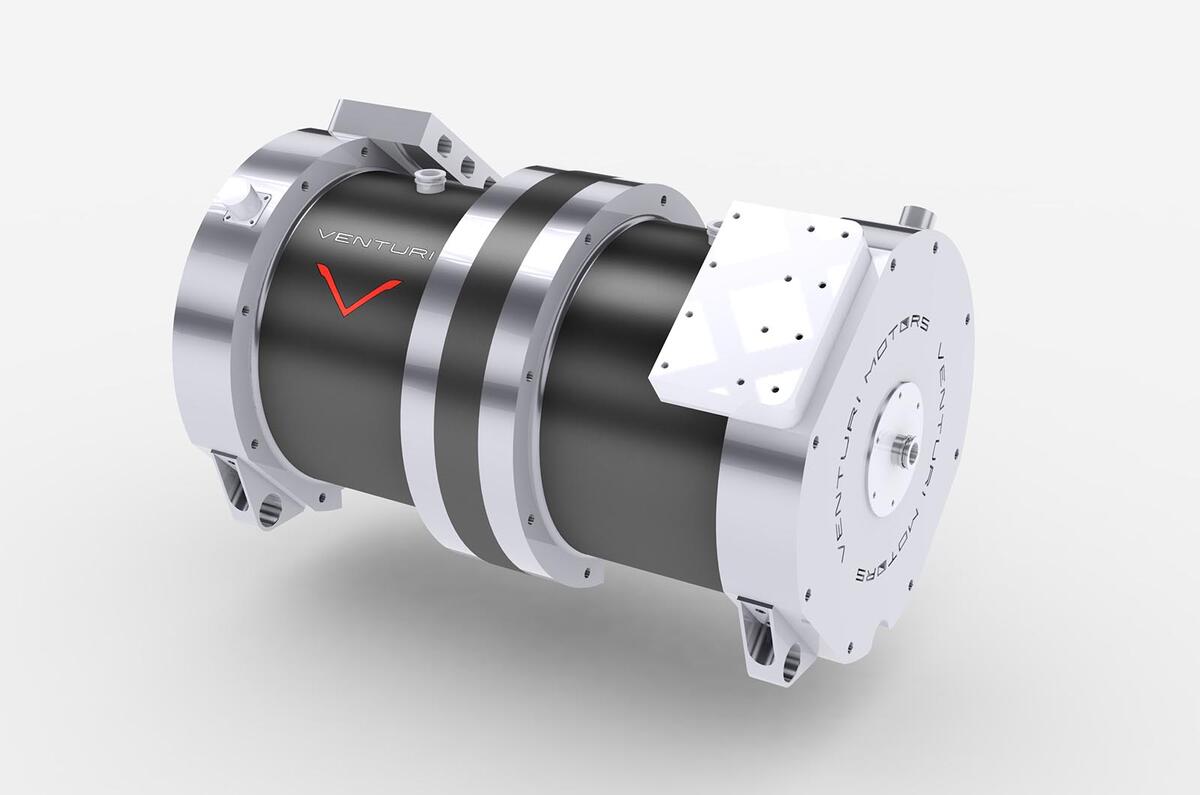

VBB-3 is four-wheel drive, with two identical but independent drivetrains front and rear. Each comprises two electric motors coupled to a common shaft, feeding more than 1000bhp to the axle through a two-speed gearbox that’s made in the UK by Hewland. The torque split between front and rear axles is variable, with a front-biased split preferred in order to avoid 300mph powerslides…

In 2015, all runs were made either entirely in first or second gear, inherently compromising either top-end speed or low-down acceleration. This year, with a full day of test runs behind them, the team got the 3.5-tonne streamliner changing gear without upsetting its stability at the 270mph shift point.

Add your comment