For the past few weeks, and many to come, Aston Martin CEO Andy Palmer has been stopping his day job at 6pm.

He then heads for the Aston Martin production line, just a minute or two from his Gaydon office, walks into a glass room and slides on a pair of white cotton gloves. With these, he will caress certain parts of whichever DB11 happens to be presented to him, devoting a good 40 minutes to the task. He will perform the same ritual with three or four DB11s in an evening, and every 10th car he will take for a short, low-speed test drive around an unusual road laid in Aston Martin’s back yard.

Palmer is fulfilling a promise. Back in July he announced that he would personally inspect the first 1000 DB11s off the production line. If the car passes, he will attach his own name-checked plaque to its engine cover, the Aston’s first owner receiving a letter detailing Palmer’s email and mobile number, should they be unhappy.

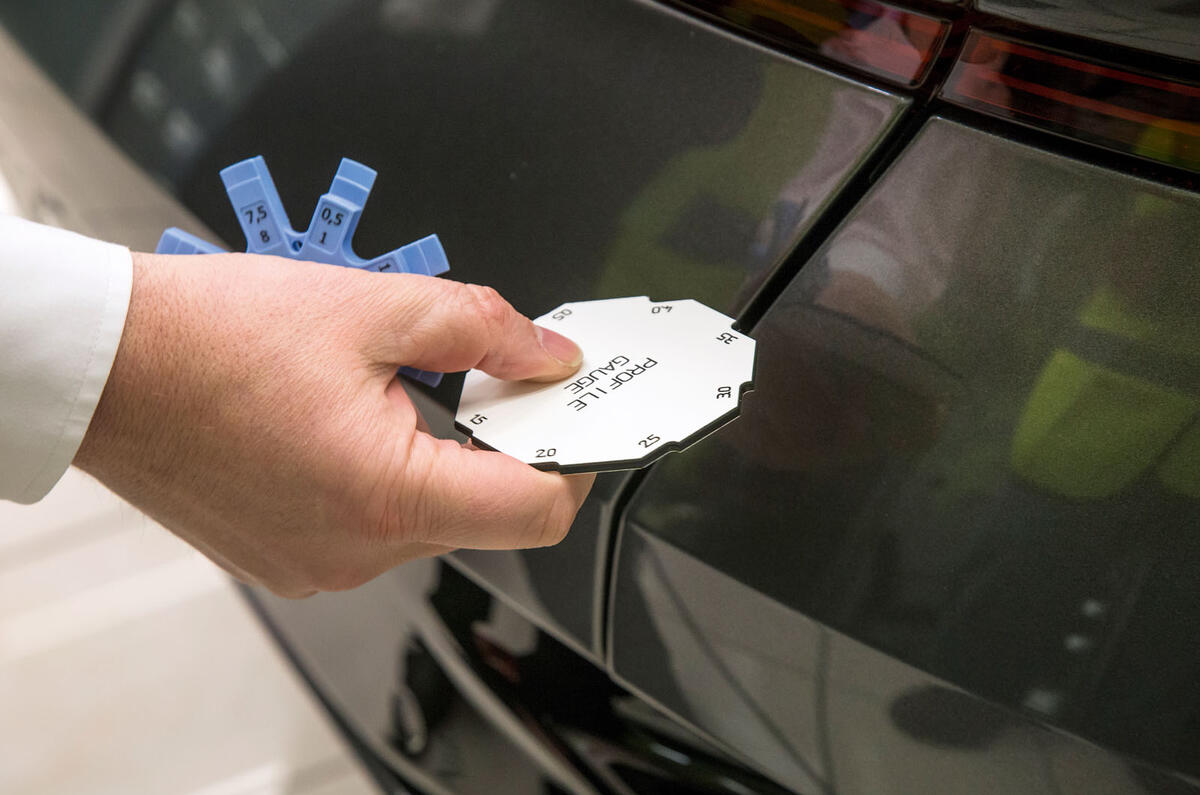

“What I’m looking for,” he says of a visual inspection process supplementing a one-hour test including mechanicals and electronics, “is stuff we’ve had issues with.” He starts by working his way “around the exterior, checking gaps, flush and overflush”. If you’re slightly baffled, gaps are the spaces between panels, while some panels are meant to sit flush with one another and others are arranged deliberately to stand fractionally proud, or overflush.

Palmer starts at the top, his gloves gliding over the roof and its boundary with a pair of strakes. These pieces flow from the base of the A-pillars to flank the roof before flaring to an elegant halt over the rear deck. They’re mounted on their own carriers, early DB11 strakes sometimes betraying small domes where clips met carrier. A cotton-gloved hand will detect these subtle protrusions; that’s why Palmer is “checking the profile of the roof strake”.

Join the debate

Add your comment

BertoniBertone,

Yup, you hit the nail right on the head! When I went sports car shopping, I looked closely at the then-current 997, among others. I bought a V8 Vantage, in large part because the build quality is superb. This has been proven over the 7 years I've owned it, in contrast to the 5 minutes you spent looking at one. It has been completely reliable – unlike the several German cars I’ve owned during those years (from Mercedes and Audi). Porsche quality is very apparent in my wonderful old 993. In contrast, recently we have from Porsche: 996/986 and 997/987 models with CATASTROPHIC engine failures due to intermediate shaft bearing failure, bore scoring problems, bore cracking problems, bore porosity problems, rear main seal failures; 991 RS engines holing their blocks and self-immolating; and Cayenne V8 engines with bore scoring problems… That’s some obsession with quality!

The 911R is a version of a 991, which has been in production for 4+ years and tens of thousands have been made. The DB11 is completely new and just starting production – to make your point by saying that the 991 911Rs didn’t need to be inspected by Porsche’s CEO to is preposterous. Is this PR stuff? Sure, but Andy Palmer is making a personal effort to ensure the quality of a ground-up new product (and providing his contact info to owners (yes, it’s real)) and you conclude that the people who build them aren’t good enough. Glass half-empty...

PR: we make crap into credible

They obviously had to have him "find" a flaw. They chose the paintwork of course. "Oooh, it takes such a long time to fix, doesn't it?"

Thing is, this PR fluff does the whole company seem stupid. What I take away from this article is:

Apparently every suit can become a quality inspector. Sure....

The regular QA (having done their work before the suit stepped in, presumably)must be shit, since they didn't catch that paint flaw.

Or are they trying to tell us there is no other QA going on? Which is silly of course.

The idea that the boss can do a better job at QA is laughable and rather pathetic. This PR piece is crap.

A shame really that Ulrich Bez had to retire. AM made better looking cars then. And they weren't so stupid about PR

What I'm reading about the