Williams Advanced Engineering has developed a new type of lithium ion battery module that could make automotive battery packs up to 30% lighter and 37% more energy dense.

The new module, unveiled at the annual Cenex low-carbon vehicle event in Bedfordshire, could have wide-reaching benefits if the tech is licensed to EV manufacturers.

The innovation means a battery of the same weight as a conventional unit can deliver longer range without compromising power, or higher power without compromising range. A test battery using 16 modules has a storage capacity of 60kWh and produces peak power of 550kW for 20 seconds, with peak regeneration of 550kW for 10 seconds.

The Adaptive Multi-Chem module is in the development phase. Williams Advanced Engineering technical director Paul McNamara says: “We could be manufacturing in a small series of around 50 units in the next six to 12 months.”

The pack is intended initially for use in high-performance premium electric sports cars and the hope is that, as demand grows, the technology will trickle down into the mainstream. The modules could also see service in motorsport and aerospace, where endurance and power combined with low weight are priorities.

Lithium ion battery packs are usually made up of a single type of cell, each with the same chemistry, energy density and power output. Cells are arranged in modules and the modules are assembled into a complete pack.

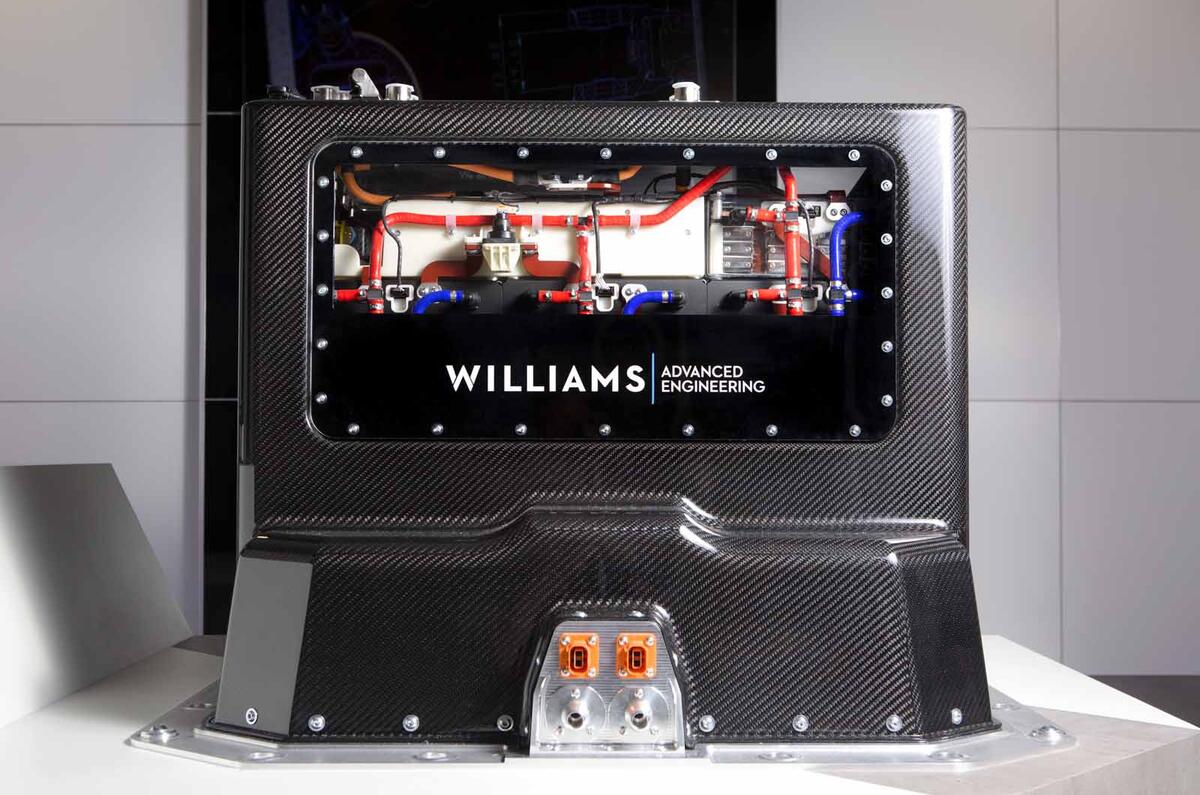

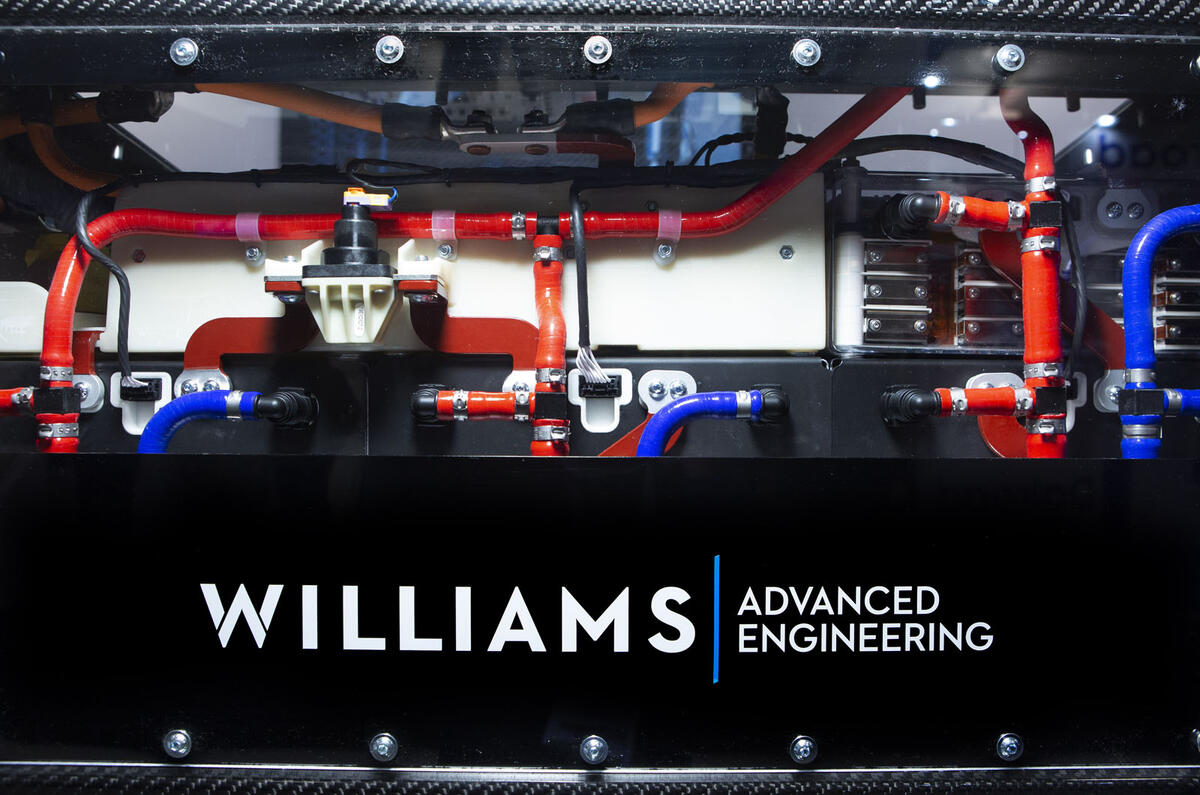

The Williams design uses two different types of cell chemistry, arranged in two separate blocks within the module. Widely used Samsung 21700 30T cylindrical cells provide good energy density and more specialised high-performance pouch cells from A123 systems provide the high power.

The pouch cells provide the fast release of energy needed for strong acceleration and, as they become depleted, are topped up again from the energy stored in the Samsung cells. Each module has its own integrated, bi-directional DC/DC converter to control the process of energy transfer between the two types of cell.

All the control software is written by WAE in-house. Each module has a self-contained liquid cooling circuit and can be supplied to customers ready to assemble into battery packs.

McNamara concedes that, because of the added complexity and integrated electronics, “the cost will be higher than a conventional module, but we hope to get economies of scale as numbers increase”.

The new design draws from experience gathered in developing batteries for the Williams F1 team and latterly as sole supplier to the FIA Formula E race series, as well as involvement in a number of electric vehicle programmes.

Read more

Chinese start-up Seres searching for UK battery partner

Volvo signs multi-billion dollar EV battery supply deal

Under the skin: Why solid-state batteries are a big positive

Join the debate

Add your comment

solid state is the way to go

But probably 5 to 8 years away,I suppose all the so called new tech in Tesla and VW Porche and Jaguar will be soon outdated or at least within a few years.I expect battery cars to depreciate substabtially.

Sounds like

a misleading story to me, I dont think that williams are making any cells themselves it's just a "lash up" of existing technology tailored for racing where the device only has to be reliable for 2 hours at a time.

Agree...

...misleading

The Lotus Evija uses Williams

The Lotus Evija uses Williams tech does it not? Is it getting this battery?

Williams

I can see them dropping out of F1 in the not to distant future. Fast charging is where it's at, you only have to see what Porsche are doing to see where BEVs are heading.