A new in-wheel electric motor designed to make it easier and quicker for manufacturers to develop EVs is due to enter production later this year.

The weight-saving technology, called the Protean Drive, has been under development by Farnham-based Protean Electric for the past eight years.

“There are a number of different applications for it,” explained Protean’s Gabriel Donaldson. “It can be used for two-wheel-drive EVs, to hybridise an existing vehicle or to convert a two-wheel-drive vehicle to four-wheel drive.”

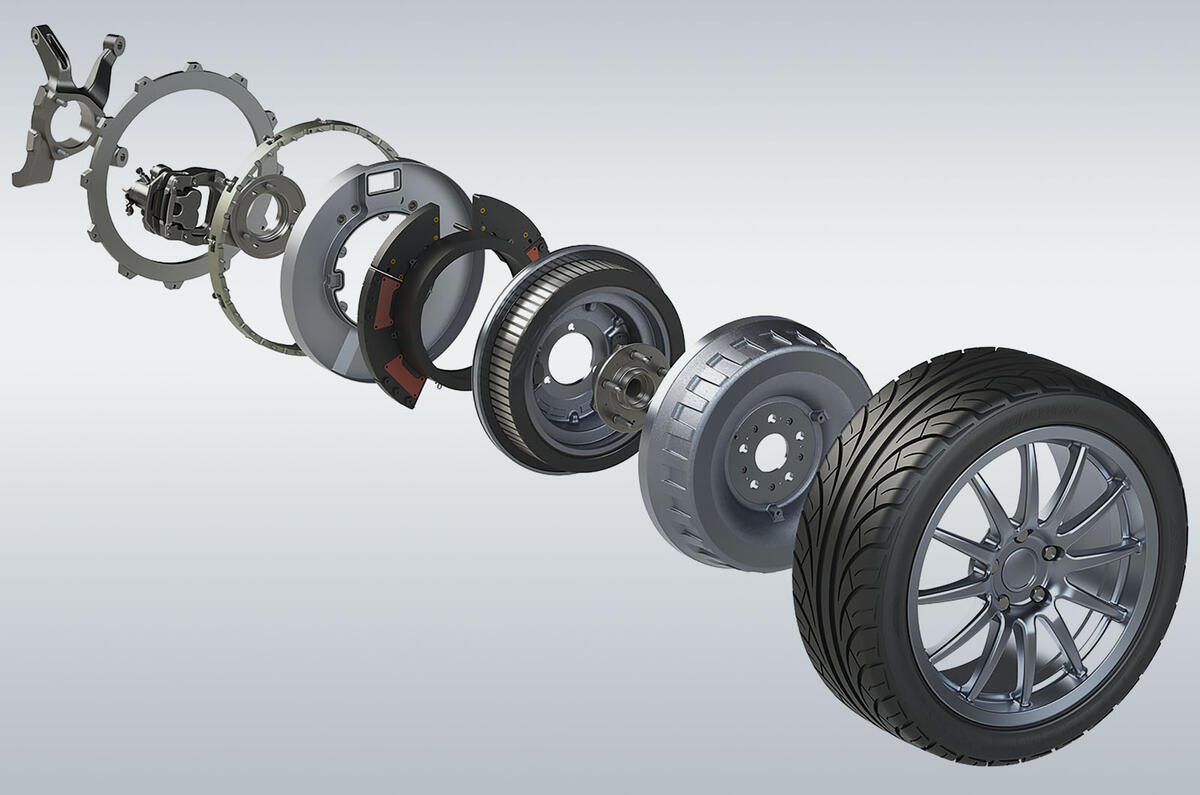

The Protean Drive is a completely self-contained ‘smart actuator’ that includes a permanent magnet and synchronous electric motor, as well as the electronics needed to make it work. Each motor produces 81kW (109bhp) and 922lb ft, so a two-wheel-drive electric vehicle could conceivably produce peak power and torque of 160kW (214bhp) and 1844lb ft.

Using self-contained wheel motors such as the Protean Drive eliminate transmissions and driveshafts and free up space in the centre of the car between the driven wheels. Cabling is minimised – two cables supplying power and another smaller one used by the main vehicle computer to control the motor.

Donaldson says that, at 72kg, a pair of the motors weighs 30kg less than the electric drivetrain of a BMW i3 (102kg). However, the wheel motors still weigh more than a conventional wheel.

With that in mind, the Protean Drives were fitted to a Volkswagen Golf, the suspension of which was tuned by an independent vehicle dynamics expert. According to Donaldson, the additional unsprung weight was managed successfully and the test car was made to handle as well as a standard VW Golf GTE.

Eliminating transmission reduces friction losses by 6-8% compared with a conventional two-wheel electric drive system. The extra efficiency is a benefit during both acceleration and deceleration, so more energy is recovered during regenerative braking.

The Protean Drive can be produced to fit wheel sizes from 14in to more than 20in. It is currently in pre-production and will be built in China, initially at the rate of five to ten units a week.

Although there are significant packaging and efficiency benefits, the technology is more expensive than a conventional electric drivetrain and work is continuing to make it more price-competitive. “Although there are commercial benefits in using it,” says Donaldson, “nobody will pay more for it.” A Chinese vehicle manufacturer will be the first to adopt the technology this year.

Join the debate

Add your comment

A little late to the party?

For all of you claiming that additional 35 kg is no go, that is not true, because those 35 kg are not rotating around the axis, so it doesn't matter that much where they are.It is the same as if you would split ICE's mass and put two halves on the farmost left and right sides of the car.

in-wheel.com

in-wheel.com

For all of you claiming that additional 35 kg is no go, that is not true, because those 35 kg are not rotating around the axis, so it doesn't matter that much where they are.It is the same as if you would split ICE's mass and put two halves on the farmost left and right sides of the car.

tnx for the info!

tnx for the info!