If there were a British car company in existence today, with a workforce of 27,000 people in 20 countries, that harboured so much design capability that its expertise were evident in half of the 80 million cars made last year globally, its brand would be a household name, right?

Well, there is a British car company that fits the bill, but for the insertion of one extra word: components. This UK-based global business is actually a car components manufacturer, but because its core products don’t actually roll on their own wheels, it sits somewhat below the radar compared with a Vauxhall, a Land Rover or even an Aston Martin, all of which are puny by comparison.

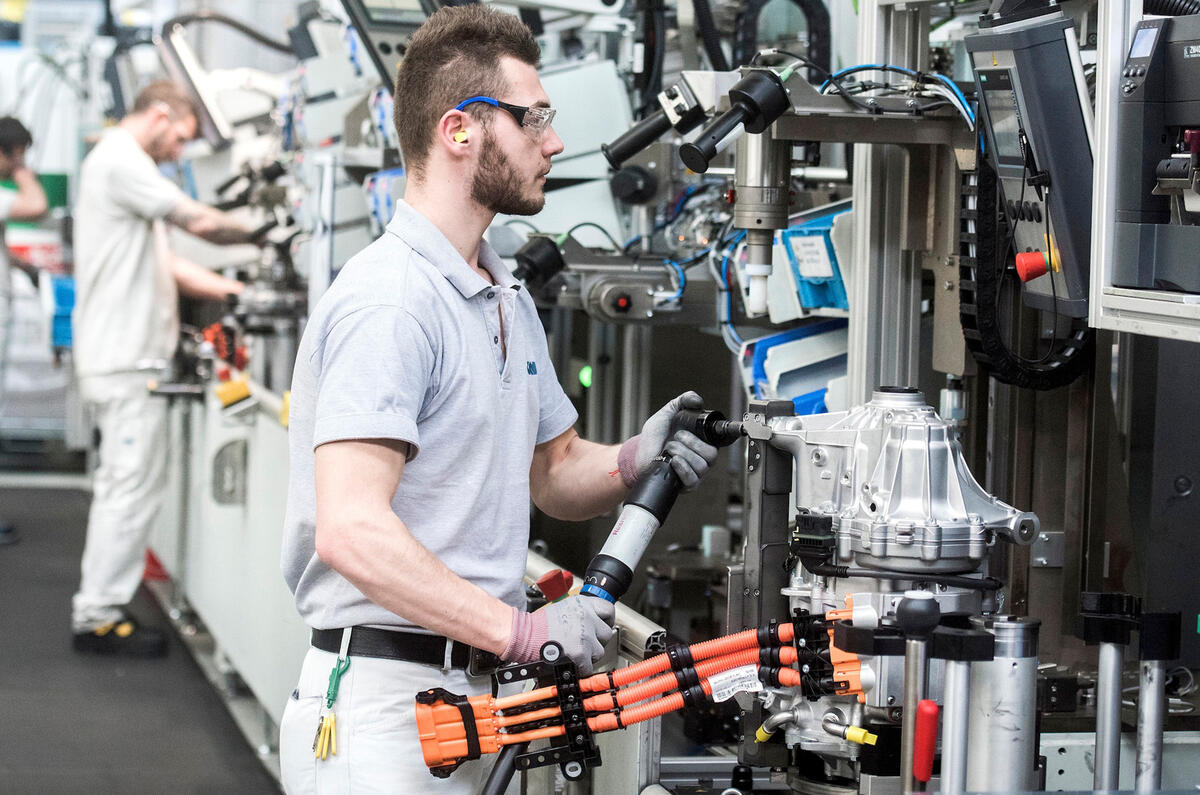

The company is GKN Automotive, a London-based technology group that bills itself as the global leader in automotive driveline and e-drive systems. It has six R&D sites and 51 factories around the world, made 80 million driveshafts last year, is a “trusted supplier” to 90% of the world’s car makers, generated annual sales worth £4.7 billion in 2019 and aims to do even better this year, buoyed by rapid growth in demand for its electric drive systems, which can mean motors, gearboxes, axles, inverters and power electronics.

But even this isn’t enough for GKN’s ambitious CEO of the past three years, Burnley-born Liam Butterworth, who recently unveiled plans to double the firm’s size by 2030 by staying at the leading edge of the rush towards electrification.

Already the leader in integrated e-drive systems (1.5 million EV propulsion systems delivered to date), GKN recently announced a move into advanced 800V tech, honed via a partnership with Jaguar Racing in Formule E. According to Butterworth, this will “create faster-charging cars with improved driving performance, battery range and even greater efficiencies.” Experimental 800V GKN systems are already undergoing advanced development in real-world applications.

Unlike other EV specialist companies whose progress is often geared to the uncertainties of battery progress, GKN’s driveshaft-plus-edrive business promises relatively hassle-free expansion, as long as it can continue to handle the need for rapid change. In 2019, around 90% of GKN’s products went into internal combustion vehicles, but by 2025 the company forecasts that the ICE proportion will have halved, with mild hybrids making up 29% of its market, full hybrids accounting for 11% and battery EVs taking 15%.

Meanwhile, the global car market continues expanding as emerging markets accelerate: GKN believes 102 million cars will be made in 2030, compared with 89 million in 2019.

Join the debate

Add your comment

A great business and Melrose were extremely lucky to capture it.