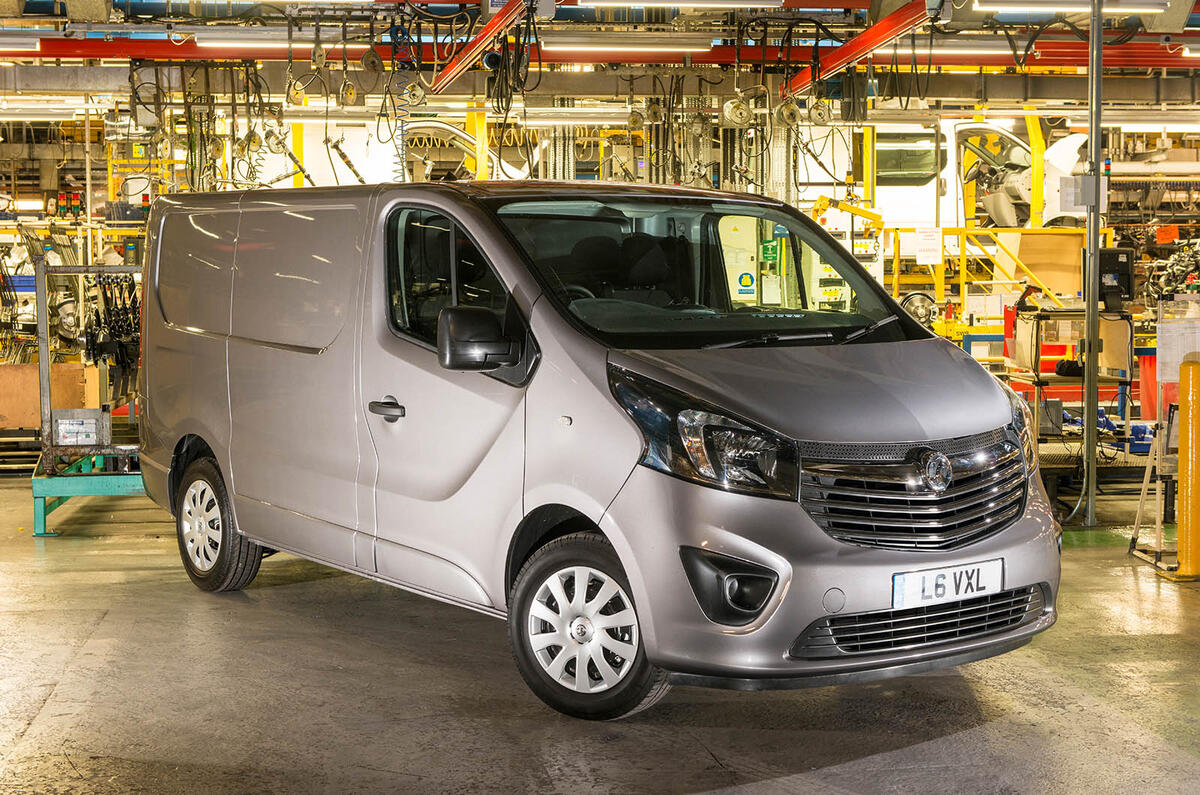

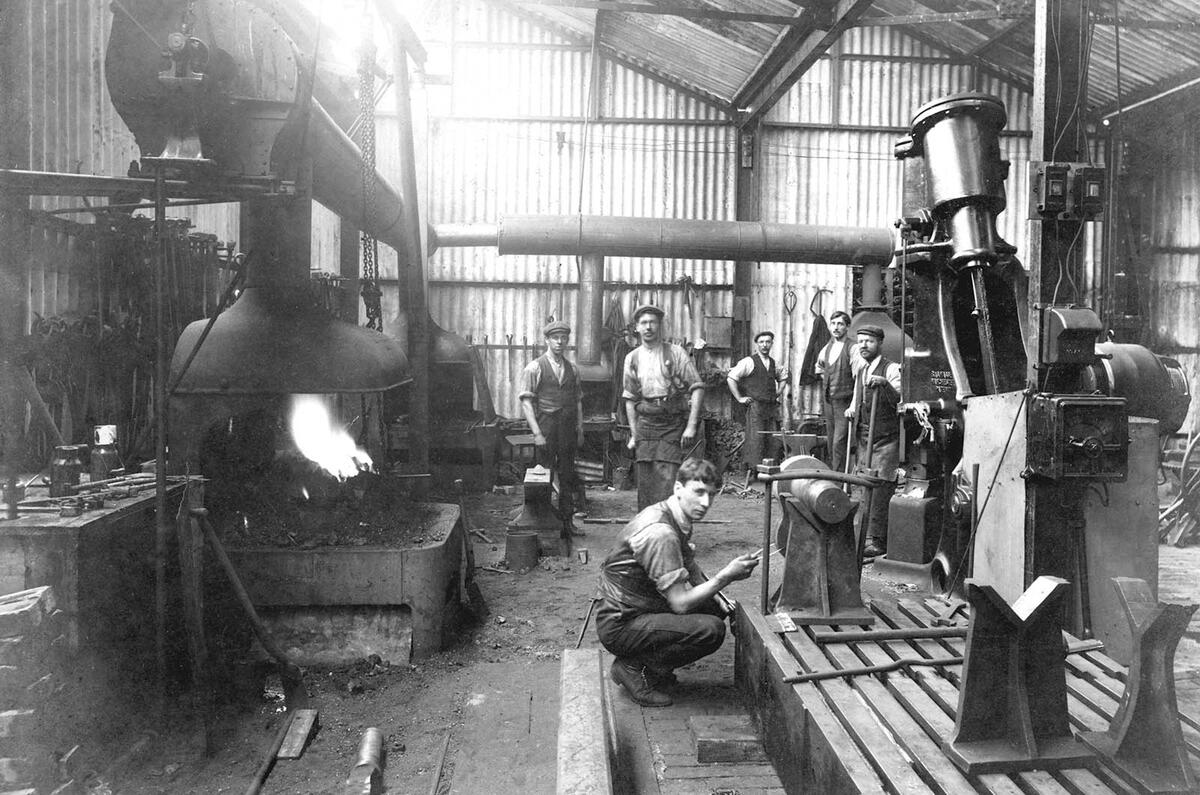

Britain’s longest-running automotive factory is General Motors’ Vauxhall facility in Luton, where vehicles have been built continually since 1905.

It may not build cars any more, but the 35-hectare site is now the jewel in the crown of Britain’s commercial vehicle-making industry.

This comes as the result of a £168 million investment to build a new generation of the Vivaro van, guaranteeing the plant’s future until at least 2025.

Luton, once home to the Viva and Vectra, is now Britain’s biggest commercial vehicle plant since Ford pulled Ford Transit production out of Southampton in the middle of last year.

Significantly, the amount of raw material and parts supplied locally for the Vivaro has also been raised to 40 per cent (up from 25 per cent), boosting the cash spent with UK-based companies by £60m a year.

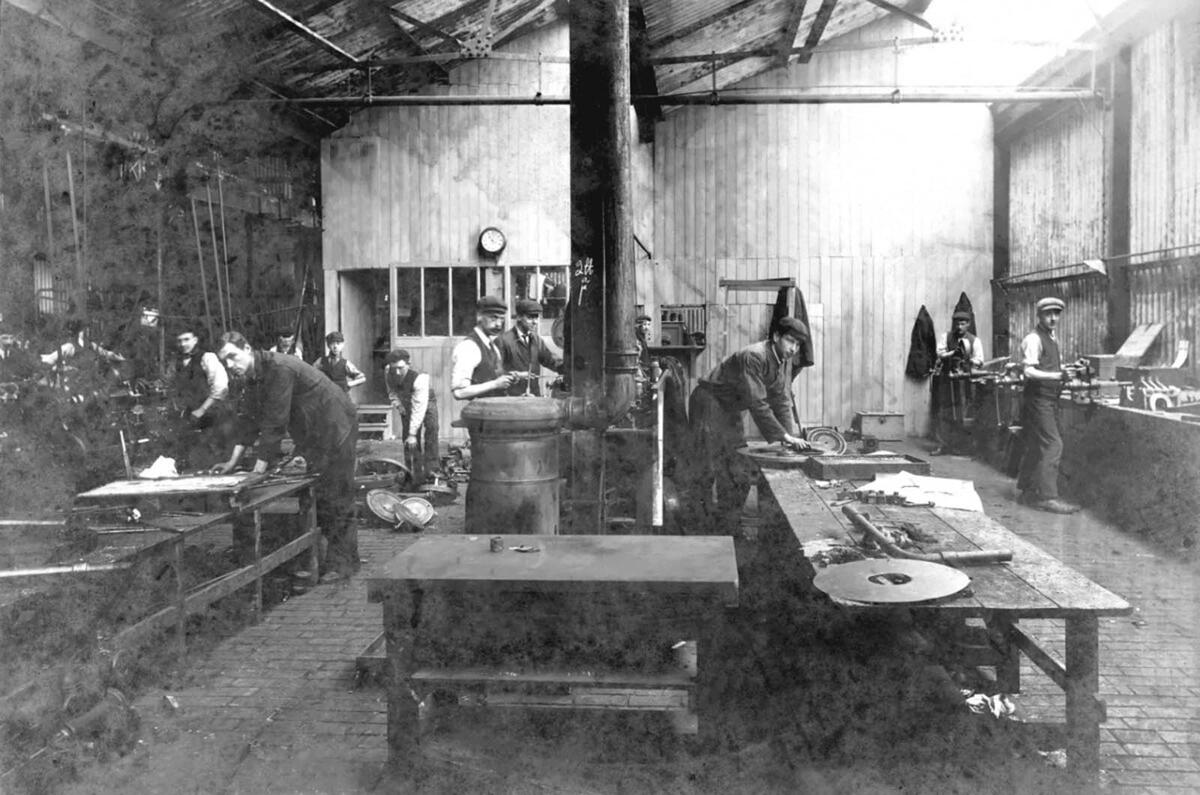

While van making may not sound glamorous, the manufacturing challenges match those of a car. It also requires equal engineering expertise and stretches the workforce in the same ways.

Luton is also a true manufacturing plant, taking raw steel coils from Tata Steel’s British mills into a press shop where panels are bashed out in traditional style before being welded into bodies, painted and assembled into final vehicles.

All this is done to the same quality standards present in any of GM’s global car plants, despite Luton having to be sufficiently flexible to build 102 body variants.

These different versions add up. There are multiple options for long and short-wheelbase platform lengths, van or minibus side panels, van or minibus floor panels, side-loading doors on the right, left or both sides and twin or single rear tailgates.

“We have to cope with considerable variety on our line and deliver a high level of quality that would no doubt surprise many car drivers,” says Mike Wright, the Luton plant manager.

Production tolerances such as panel gaps are catching up with cars, too, which means a higher level of accuracy in the press and body shops, and during final assembly.

“Vans used to have lesser tolerances, such as 6mm, but now we’re talking a fit of 2mm on some panels,” says Wright.

Luton, which employs 1200 workers, is gearing up for increased production ahead of the Vivaro’s launch this month. The initial plan is to build around 45,000 a year on a single shift, with around half of those going overseas.

Expansion plans, however, call for an extra shift of up to 500 people in 2015/16 to lift totals closer to 65,000 a year – a significant boost to UK plc’s overall vehicle production.

The challenges involved in making a van

Line speed

The production line at Luton operates on a two-minute ‘cycle’ – the time allowed at each of the stations where operators screw, clip or bolt on components.

That reflects the greater complexity of the processes at each station and the reduced automation compared to car plants, which are typically timed for a faster one-minute cycle.

Production efficiency

There are fewer parts in a van than in a car, with 2830 in the Vivaro compared to around 4000 in a typical car. Building each Vivaro takes 24 man hours.

That’s less labour-intensive than a mid-size car, which typically takes around 30 hours. A low-cost city car is faster – thanks to increased automation – and might be as low as eight to 10 hours.

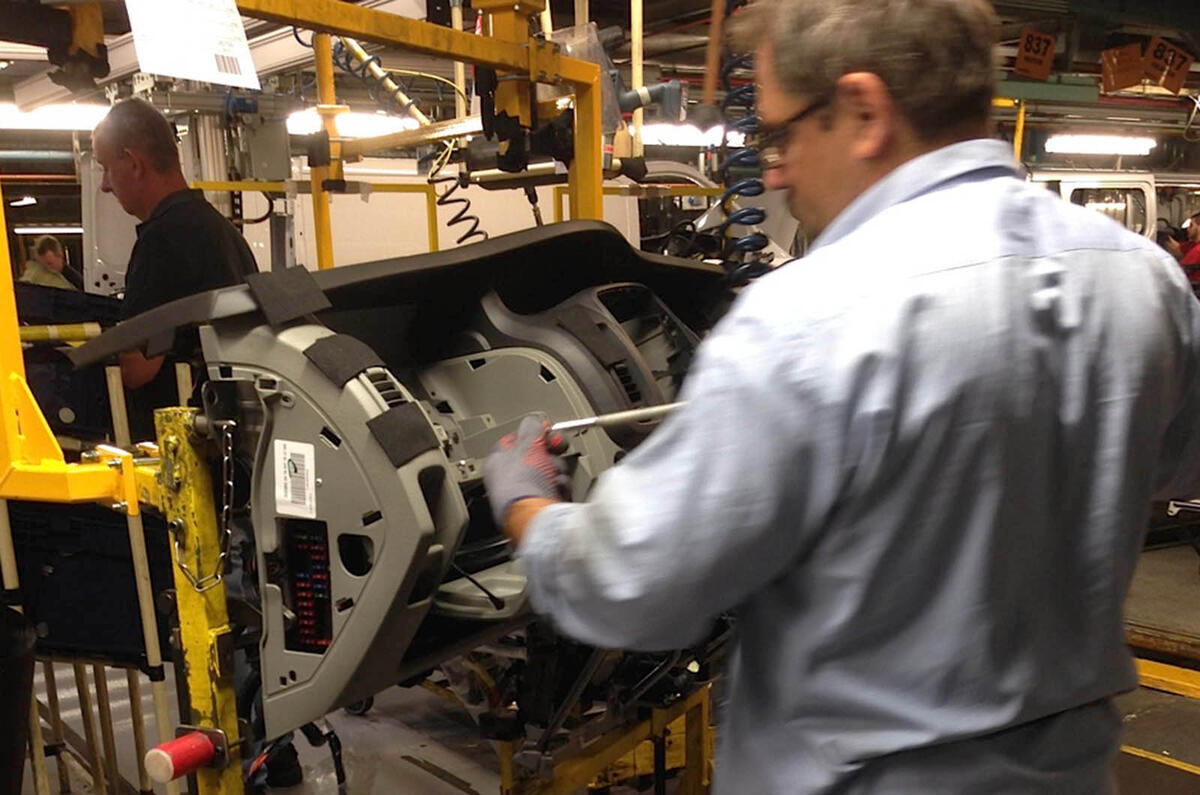

Dashboard

Luton is unusual in having a dedicated dashboard assembly line. Usually, a car dash is supplied as a built-up module ready to plug into the wiring harness.

That’s possible because the higher production volumes in a car factory – typically 250,000 vehicles a year, about five times that of Luton – can justify the tooling costs and outsourcing.

The new model

The new Vivaro is based on a carry-over platform and shares its 3098mm wheelbase with the outgoing model. The rear overhang, however, is longer, which adds just enough load space to accommodate a 6ft x 4ft sheet – addressing a particular criticism from builders.

The floor, meanwhile, has been retooled because, after 13 years of continual operation, the press tools have limited life left.

Body side station

In the framing station, the floor, roof and body sides are welded into the body-in-white (the unpainted bodyshell). The station has one of the most complex tools you’ll ever see in a factory. Each body side is made up of three panels – front door opening, centre section with or without door opening and tail panel.

Each of the three panels has to be held in place with vacuum suckers before flipping through 90deg and being spot-welded into a recognisable side.

The tool is complex because it has to handle such a variety of parts, each requiring its own vacuum sucker.

Renault / Nissan

Luton used to build Nissan and Renault versions of the Vivaro at Luton, but won’t from now on. Nissan has gone its own way, while Renault has concentrated production of the Trafic in France.

The Vauxhall/Opel and Renault versions are still essentially the same vehicle with different badges, however, and Vauxhall says the shared 50/50 cost of the £400m investment in the project is what makes the business plan viable.

Pressed parts are also shipped between Luton and France, which takes 12 hours via the Channel Tunnel.

Press shop

Raw steel coils hundreds of metres long and from British and continental strip mills are delivered to Luton. Coils have to be ‘blanked’ – cut into a shape designed to fit the press tools — before undergoing up to five pressing operations.

The last of the five ‘hits’ finalises the shape and prevents ‘springback’. The process is identical for cars, although faster and more expensive ‘transfer’ presses are typically used to generate the higher production volumes required in car plants.

Workforce versus robots

About 65 per cent of the cost of production at Luton is labour, reflecting the low level of automation. The only robots are in the body framing welding shop, dictated by the size of the panels and the danger of the operation.

Car plants employ more robots because the cost of speeding up production is justified by the higher sales volumes.

Get the latest car news, reviews and galleries from Autocar direct to your inbox every week. Enter your email address below: