Work has started on a package of aerodynamic innovations for the next generation of Volkswagen Golf, according to company sources.

The Mk8 Golf, which is due in 2019, will have to be one of the most economical mainstream cars ever built. VW engineers and designers have already started to investigate ways of reducing the average CO2 output of the next range of Golf models to well below 90g/km.

It is understood that VW will be using the lessons learnt from the radical two-seat XL1, which makes extensive use of aerodynamic innovation to help it achieve 313mpg.

The fact that early work is already under way on a car that is still at least five years from the showroom indicates the hurdles that face all car makers in meeting the European Union’s rigorous fleet-average CO2 emissions standards, which come into force in 2020.

Although VW sells proportionally far more Golfs and Polos in Europe than it does bigger and less economical vehicles such as Volkswagen Passats and Volkswagen Tiguan SUVs, figures supplied by the EU suggest that VW – along with most other European car makers – will still have to reduce the average CO2 output of its future fleet by between 22 and 27 per cent.

Given the need for such a significant reduction in average fuel consumption, VW engineers are unlikely to be able to just bet on another round of engine improvements, instead, they are likely to need to exploit every new trick in the book, including the most advanced aerodynamic treatment yet seen on a production vehicle.

According to a VW insider, “a number of aerodynamic solutions are being investigated [for the Golf Mk8]”. However, according to the source, a fundamental difficulty facing the engineers and designers is that, proportionately, the Golf is quite a short car.

The XL1 has been shaped primarily for aerodynamic efficiency so it is both low and long. However, the Golf, by definition, is a family-size hatchback and that effectively sets the car’s proportions.

VW also has to consider that mainstream buyers may not want a car that loses its character to the demands of cutting-edge aerodynamics.

For example, the sharp-edged rear corners of cars such as the Toyota Prius and Chevrolet Volt improve the way that the airflow ‘breaks off’ the body, but they could probably not be used for the Golf Mk8. However, one solution could be to extend the hatchback’s rear spoiler further over the rear window, along with deep blade-like extensions along the upright sides of the window.

The Golf Mk8 will be based on the MQB platform and be built from conventional stamped and welded panels. This means that the car will be no wider or longer than today’s Mk7 Golf. However, VW will have to find further weight savings in the new car, bringing the base kerb weight under 1100kg.

It seems unlikely that VW will invest in aluminium for any of the Golf 8’s exterior panels, because cost control will also be a major issue for the new car. With the likely addition of complex new technology, keeping the factory build cost down is of paramount importance.

Meeting the impending CO2 regulations, which will almost certainly add hundreds of euros to the cost of building a car, could prove devastating for many mainstream car makers that are surviving on very slim profit margins.

New Golf's fuel-saving tech

Flywheel

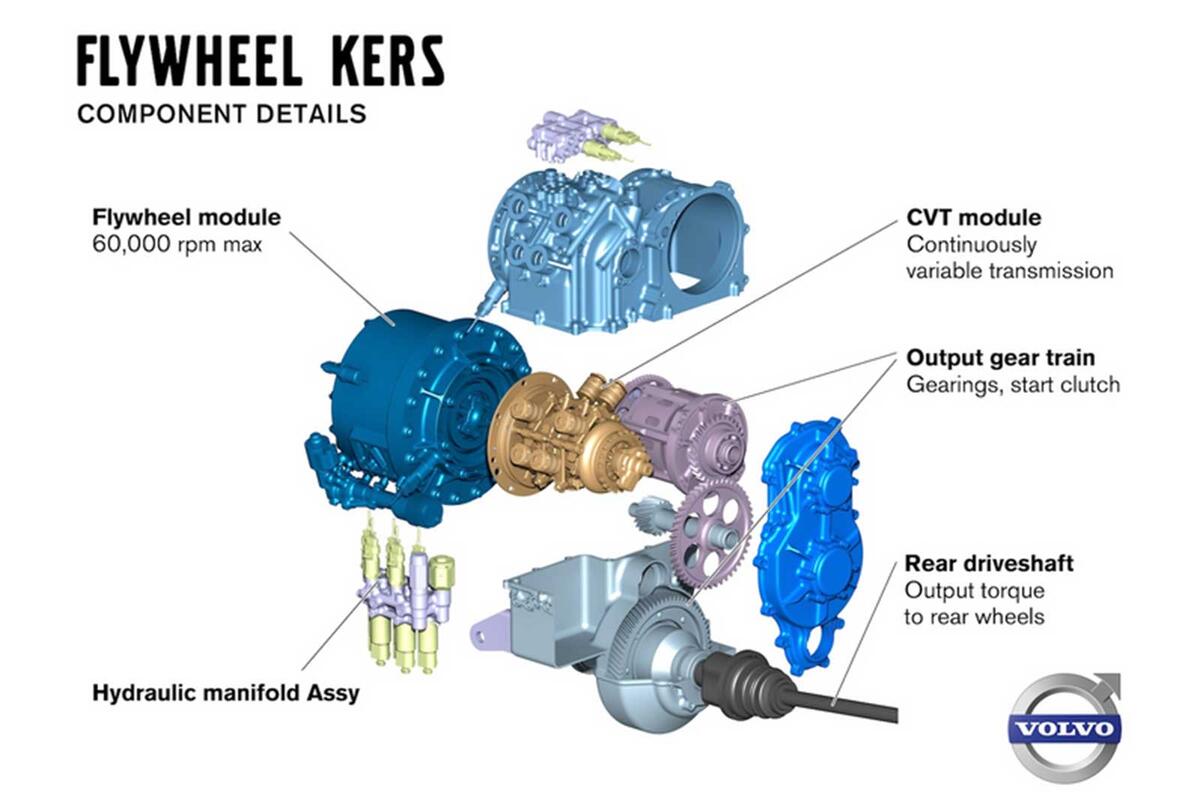

Volvo is already testing a British-designed flywheel system, which is used to drive the rear wheels of a front-drive car.

Flywheels could become familiar on mainstream cars in the next decade because they can store waste energy and release it like an electric motor and battery. Flywheel systems are about a quarter of the cost of a hybrid set-up, far less complex and far lighter.

Volvo’s system takes 8.0sec of braking to recharge and offers 10sec and 80bhp of drive assistance. A future Golf would likely use a unit good for 40bhp or so.

Variable compression ratio engines

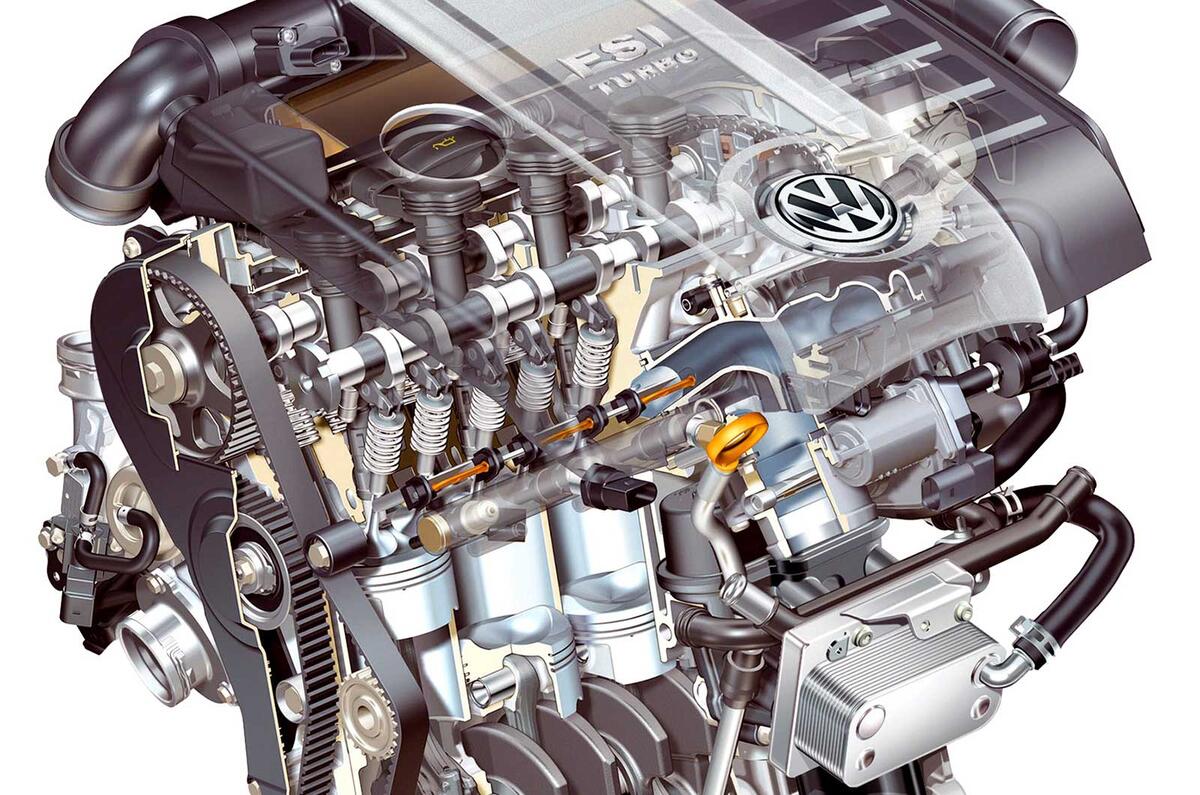

Earlier this year, Audi technical chief Ulrich Hackenberg announced that the Volkswagen Group was developing engines with variable compression ratios.

Hackenberg didn’t reveal any details about how this will be executed, but the principle has long been an important goal for engine designers. Being able to vary an engine’s compression ratio depending on the demands being placed on it should lead to significant advances in efficiency.

Coasting

Audi’s Ulrich Hackenberg also said that coasting technology would be used in future VW Group models. Coasting technology is expected to be rolled out in three stages. The first stage – coasting at speed – is already featured on some VW dual-clutch ’boxes.

The next version is expected to function when the car is travelling below 4mph. The ultimate version will allow transmission decoupling and engine shut-down when cruising at speed, travelling downhill or approaching traffic lights that are about to turn red.

Electric turbochargers

Audi has already previewed its own version of electric turbocharging, which uses a powerful fan in the engine’s induction system.

This blows air through the turbo when the engine is decelerating, spinning the turbo fan up to speed, so that full boost is available as soon as the driver gets back on the accelerator.

Such a system is especially useful for downsized engines, which generate little exhaust gas energy, especially at low speed. A future Golf with, say, a 1.0-litre three-pot would have much improved driveability characteristics.

Get the latest car news, reviews and galleries from Autocar direct to your inbox every week. Enter your email address below:

Add your comment

Coasting?

XL1 tech in the Golf

For far too long now cars