Audi is working on a new bi-turbo engine which uses an electrically-driven turbocharger to completely eliminate turbo lag and markedly increase standing-start performance.

The prototype is based on Audi’s new 3.0-litre V6 TDI Bi-turbo engine, and is described by the company as being in the ‘development phase’. This experimental V6 diesel uses a conventional exhaust-driven main turbocharger with the small motor-driven turbocharger being used exclusively at low speeds.

Reducing turbo lag - the gap between the driver pressing the accelerator and the effect of the turbo’s boost - has been the subject of engineer’s efforts for three decades. The fundamental problem is the need for a sufficient volume of exhaust gasses to be generated by the engine and then directed at the turbocharger, in order to get it running at high speed.

However, when the engine is running at lower speeds, the volume of gas isn’t enough to spool the turbocharger up to its operating speed. Current turbocharged engines get around this problem by using two turbos. The smaller turbo can be brought into action with smaller volumes of exhaust gas and bridges the gap until the bigger turbo can be brought into play.

Audi’s new system, however, totally eliminates lag, greatly boosts low-speed performance and is fundamentally simpler than the twin-turbo and triple turbo set-ups used by the likes of BMW.

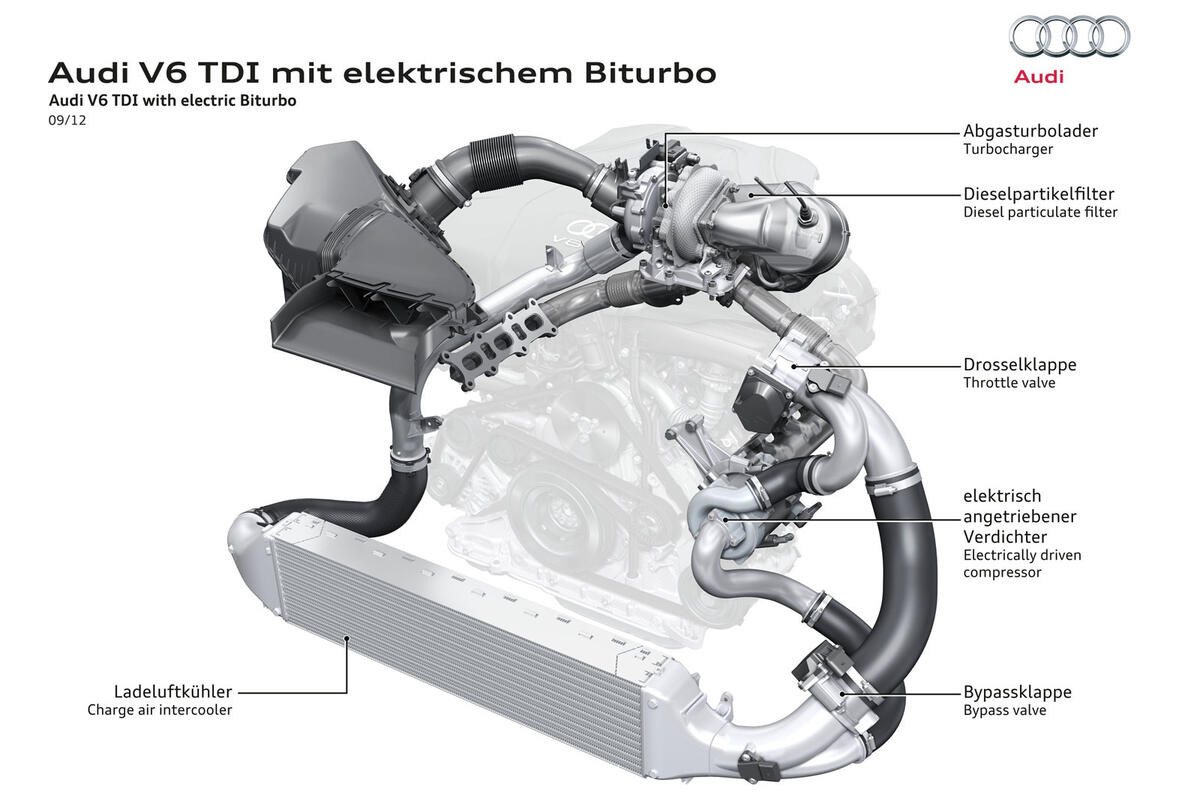

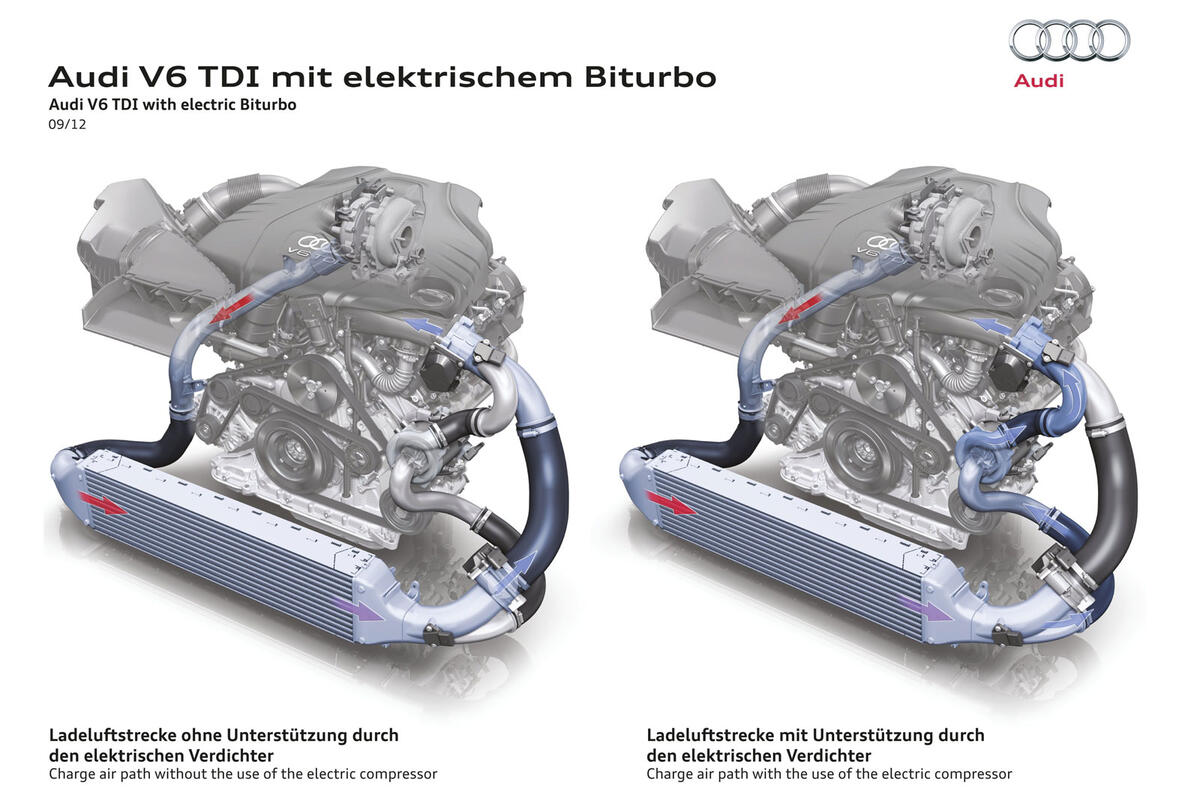

Audi’s electric turbocharger sits in the induction system, downstream of the conventional turbo and the intercooler and is normally not operative. However, at very low speeds - particularly from standstill - the air charged by the main turbo is re-directed through the electric turbocharger, which is already spinning at high speed, and pushed with much greater force into the engine.

A brief drive of a prototype unit in an Audi A6 showed the electric bi-turbo set-up to be dramatically effective. The torque boost from a standing start with the electric turbo in operation delivers what can probably be described as sub-supercar performance. Audi’s own tests claim that, back-to-back with a conventional V6 TDI, the electric Bi-Turbo car was two car lengths further down the road just three seconds after launch.

This early prototype showed there was a just-definable dip in the torque delivery as the electric turbo gave way to main the turbo, but it is clear that electric turbocharging is set to significantly enhance the performance of forced-induction engines and deliver a step-change in the standing-start performance.

There’s no news on when the system will go into production, but the next-generation 2014 Audi A4, bases on the new alloy-steel hybrid MLB platform, looks likely to receive this engine.

Join the debate

Add your comment

Return to sender

Yes agreed. I has to work like that other wise the electric thingy wouldn't be able puff at all !!

My point was that the diagram doesn't show a by-pass mechanism in operation when the input charge is being re-redirected to the electric compressor.

Shhhimple.

Sender back.

Bypass v/v; lower right in image 2.

Low pressure?

At really low speeds the main turbo isn't spinning very quickly at all and hence not generating much input charge pressure.

So how come the electric compressor doesn't just get starved of input charge and generate a low pressure area between the main turbo and its own input?

If the purpose of the electric compressor is to boost input charge pressure, then surely there will be a significant differential between the output of the main turbo and the output of compressor itself.

The diagram shows only a redirection of input charge after the charge cooler, so is there a missing detail that Audi hasn't revealed? A main turbo by-pass perhaps?

Hmmmm. Answers on a post card please.

Post card answer.

The electric blower, (come on lads, it ain't a T/C) takes suction from atmosphere, through the air inlet filter, T/C compressor casing, charge air cooler, etc., and therefore can't be starved.

At low rpm, the bypass valve in the charge air cooler to T/C air inlet pipe will be closed, with the blower in operation. At upper P setpoint the blower stops and the bypass valve opens. At lower P setpoint vice versa.

Easy-peasy! It only takes on mild complication when installed on a 2-stroke diesel crosshead engine with uniflow scavenge air, pulse turbo-charged with cylinder port induction and valve exhaust!

-

These systems have been doing the rounds for a couple of years and major component suppliers like Valeo have acquired the technology for manufacturers to start taking advantage of.

This electric turbo has all the benefits of a supercharger without the CO2/fuel consumption punishing downsides. Seems to work well according to Hilton.