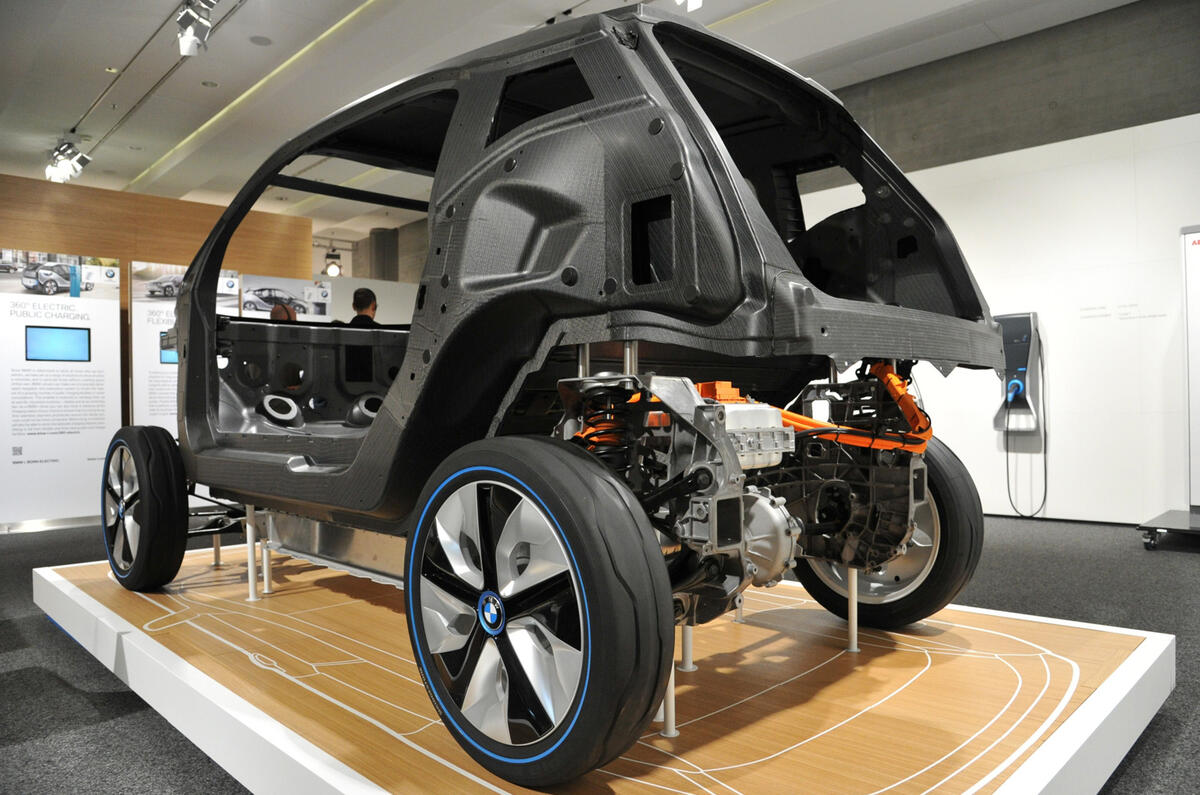

BMW has developed new processing and production techniques that make carbon fibre a viable material for use in large-scale automotive production.

The manufacturer intends for carbon fibre to feature more prominently in its future models as a result. As well as potentially improving safety, by providing a more rigid structure, carbon fibre reduces weight. This can lead to improvements in performance and efficiency.

Due to be launched soon, the new BMW i3 will be the first series production car to extensively feature carbon fibre, with its entire body structure being made from the material. It will be closely followed by the i8 sports car, which also uses carbon fibre in its construction.

Previously, the material was considered too time-consuming, costly and difficult to utilise - in significant amounts - in mass-produced cars.

Over ten years’ worth of research, however, has allowed BMW to acquire the expertise required to reduce the processing time of carbon-fibre components and panels, even complex ones, to a period short enough to allow for high volume production.

"Compared with initial industrial production of carbon-fibre M3 roofs, we have succeeded in lowering manufacturing costs for carbon-fibre body components by as much as 50 per cent", said Harald Krueger, board member of the BMW Group.

"Our manufacturing concept for the M3 roof was the first to reduce production time to minutes and assure the necessary quality in series production. In the BMW i3, we were able to reduce production cycle times for carbon-fibre body components by a further 30 per cent."

Key developments that allow BMW to produce carbon fibre on such a scale include new bonding techniques, allowing carbon-fibre parts to be joined faster, and a new panel processing system that results in shorter manufacturing times.

The use of carbon fibre for body shells, chassis tubs or myriad panels had typically remained exclusive to low volume sports cars and supercars, like LaFerrari.

Join the debate

Add your comment

Watch and learn

I don't know the technicalities involved in the process of making the carbon fibre nor would I pretend to know how it reacts to the daily wear and tear or crash damage.

What I do admire though is that a car maker is investing time and money to develope the stuff that the future cars could be made of. Others are sitting on the sidelines.

A brave move

This shows how different manufacturers come up with different solutions to weight saving .

I dont think carbon fibre is the best solution . Aluminium alloys are easier and cheaper to produce and repair and not much heavier . They are easy to recycle too .

wave goodbye to relatively low repair costs

So what happens when you have a relatively low impact shunt in a steel-bodied car ? Knock it out, pull it out, or push it out. Your local bodyshop will be able to sort it out for you.

What will happen when you have a relatively low impact shunt in a carbonfibre-bodied car ? You get a mortgage to get your car repaired.

One of the many reasons that carbonfibre is inappropriate for high-volume production is the high cost of repair.

Given the high cost of repairing carbonfibre-bodied cars, I believe that it should be illegal for anyone causing an accident with one to be required to pay more than they would have had to pay with a steel-bodied car. The balance should be paid by the carbonfibre-bodied car owner's insurer. If we don't have some such system, then all our premiums will go through the roof.

SpiritOfSenna wrote: Given

I suspect you're a bit mad

Leslie Brook wrote: R.I.P.

Amen, brother!

SpiritOfSenna wrote: So what

I'd suggest the insurer would charge more premiums as matter of course for insuring vehichles that cost more to repair. Basically the current insurance system works like that now. You can't make accidents illegal if there is someone prepared to insure them.