Have your say in our forums or by emailing autocar@haymarket.com. In particular, we’d like to know if you’d like to read more technical features along these lines, and whether you found this article too basic or too complex and too long or too short

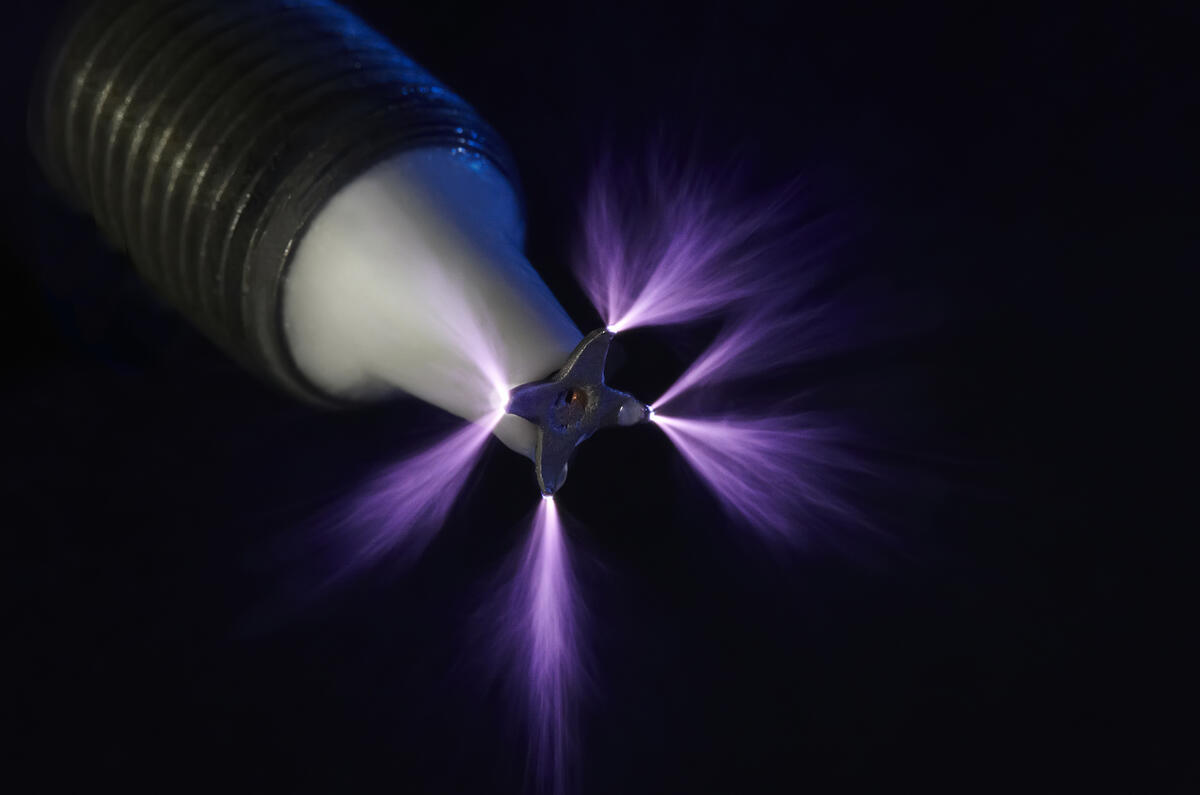

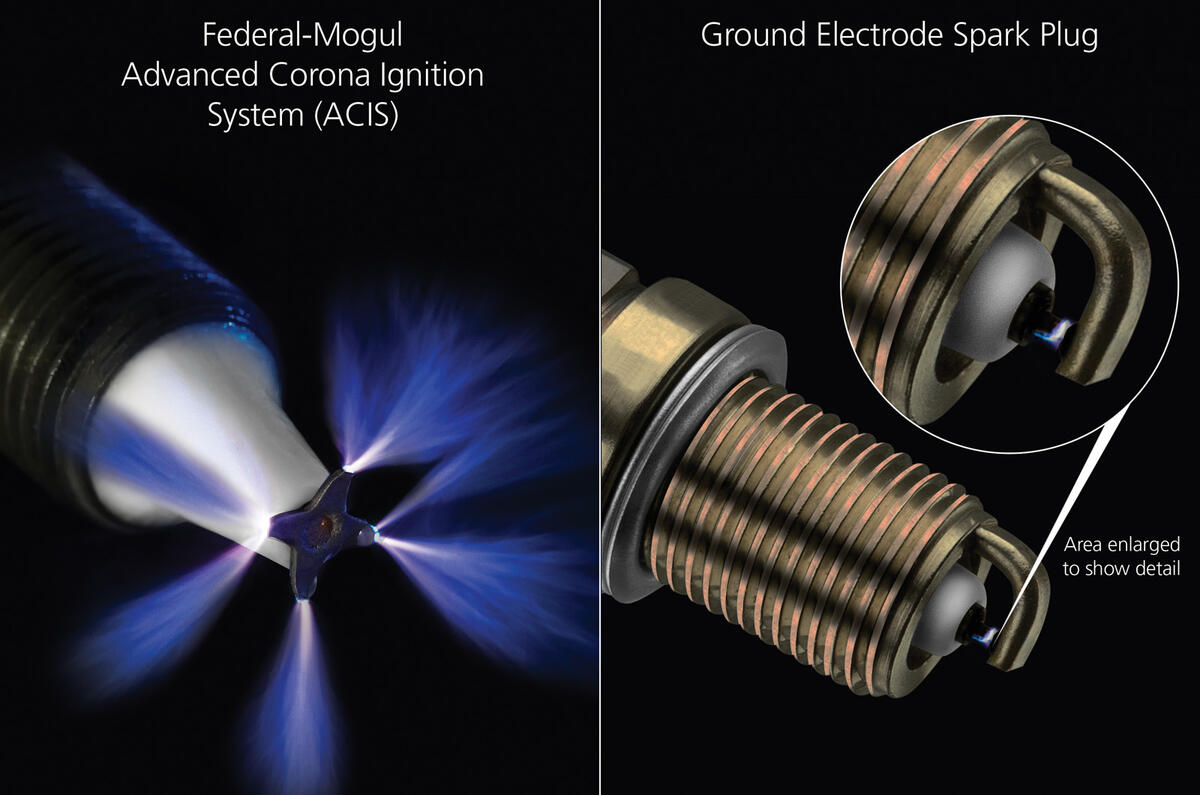

Plasma, ionisation, sparks, coronas… the words read more like a weapons checklist in a sci-fi novel, but in fact they’re all critical factors in the latest invention that promises to reduce fuel consumption.The device you see pictured is an ultra-hi-tech take on the humble spark plug. Called the Advanced Corona Ignition System, or ACIS, it’s a work-in-progress development currently being undertaken by car parts giant Federal-Mogul.Most importantly, it promises a reduction in fuel consumption of up to 10 per cent thanks to the radically more efficient way in which it operates than a standard spark plug.What’s more, if it’s a success it has the potential to give designers the freedom to alter the way they build engines in the future. Here’s how.

The benefitsA conventional spark plug works by igniting the engine’s compressed fuel/air mix from a (usually) single, (usually) central point. Combustion radiates out from the spark, accelerating the piston’s movement down on its power stroke as it does so. ACIS replaces the conventional plug’s spark with a system that creates a larger ignition source in the form of a corona around its tip.This ionises and excites the fuel mixture within the combustion chamber, which initiates combustion more quickly and more efficiently over a wider area. The extremely hot ‘plasma’ that results means that ACIS is able to ignite less easily combustible mixtures, such as those used in more fuel-efficient lean-burn engines, or those laced with recirculated exhaust gas.

Burning fast — and brightThe corona is short-lived but intense. “A conventional spark lasts for two or three milliseconds,” says Kristapher Mixell, director of powertrain energy at Federal-Mogul, “but this is more like 100-200 microseconds.And instead of happening at just one point, the corona can be 30 or 40mm in diameter. There can be combustion initiation sites all over the chamber.” This opens up possibilities of new, more efficient shapes for a combustion chamber, but that’s for the future.

Running lean…Even with current engine designs, the benefits are clear. As the fuel/air mixture burns more quickly, so the expansion energy generated by its combustion can be put to the best, most efficient use, right at the top of the piston’s power stroke.It also means that mixtures which have been leaned out for economy reasons under lighter engine loads can still be ignited easily. That means a gentle motorway cruise could be spectacularly economical.

Join the debate

Add your comment

Role of Spark Plugs