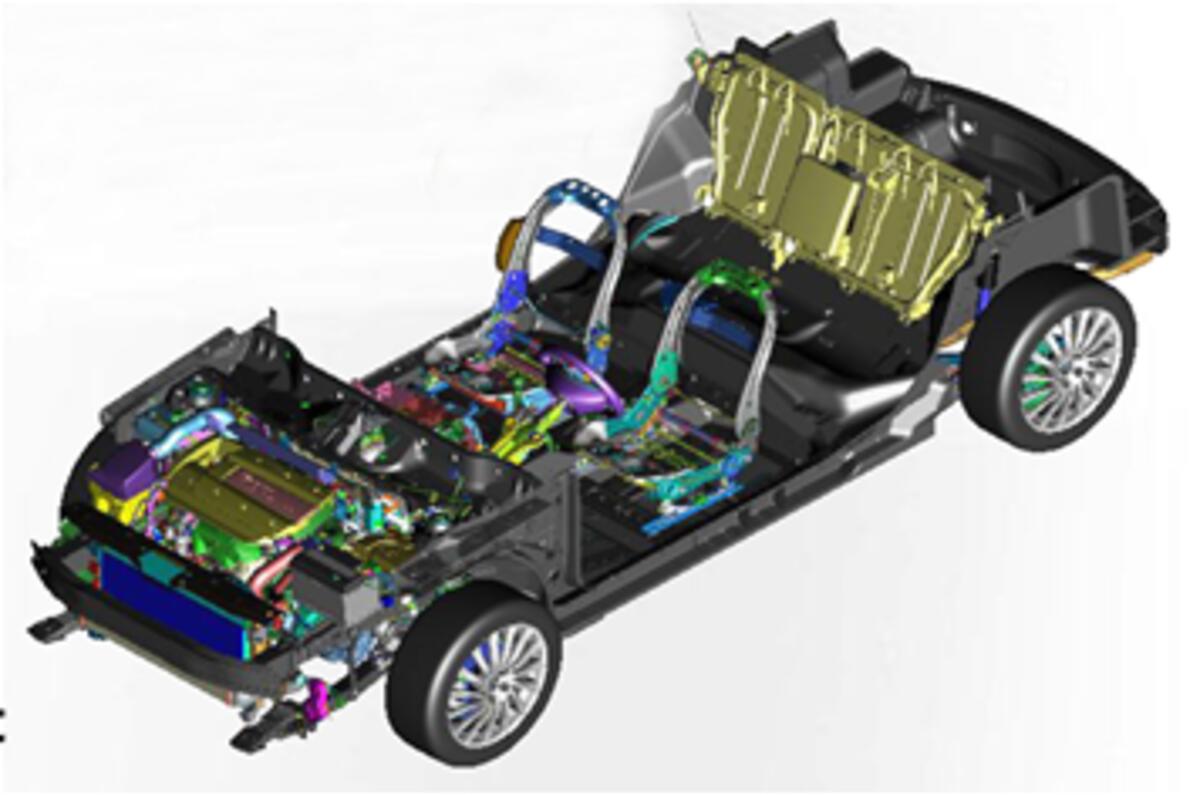

The new Compact Global Modular Architecture - used for the Giulietta and ‘grown’ to form the platform for the Giulia - is key to Fiat, Lancia, Alfa and Chrysler being taken seriously in all market segments above the Fiesta class.

Fiat has designed a modular kit of parts that will enable it to produce highly competitive models, from a new Fiat Bravo hatchback up to upmarket SUVs, all using the same basic building blocks.

The key to the success of the concept is the ability to build the Compact architecture not just in two wheelbase lengths but also in two different widths.

On top of that, Fiat engineers had to incorporate the ability to have two different lengths of front overhang, at least two different heights for the base of the windscreen, and the ability to accommodate larger wheel wells for SUV models.

In effect, the Compact platform has a common front bulkhead and front crash structure, and a common rear floorpan and rear crash structure. To lengthen the wheelbase, there’s an extra pressing that can be inserted between the centre and rear floorpan structures.

Depending on the type of vehicle, a different structure is added on top of the front bulkhead, dictating the position of the windscreen and the front door hinges. The sill structure and rear wheel housing is a single pressing that accommodates different wheelbases and wheel sizes.

According to this Fiat illustration, all vehicles based on the Compact platform will get a front MacPherson set-up, but the rear axle is either a multi-link set-up or a cheaper beam axle, depending on the model’s price point.

Add your comment